Air blower for soil remediatiom

Although the soil remediation event has gradually subsided, people’s attention to the remediation and utilization technology of toxic land has not decreased. What we want to introduce today is the technology of soil remediation and reuse.

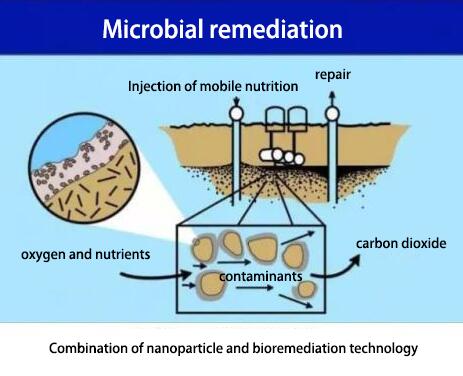

1、 Microbial remediation technology:

Equipment: mixing system, blower system, exhaust system, nutrients, exogenous microorganisms.

Treatment object: organic pollutants.

Treatment method:

(1). At least two wells should be drilled on the polluted soil, and blowers and exhausters should be installed to force air into the soil. At the same time, nutrients should be added to improve the biodegradation activity of microorganisms to decompose the pollutants, and then be pumped out.

(2). Bacteria, fungi, actinomycetes, algae and other microorganisms are dug into the soil or sprayed on the surface to produce microbial enzymes, which can promote the degradation of pollutants by mineralization and co metabolism.

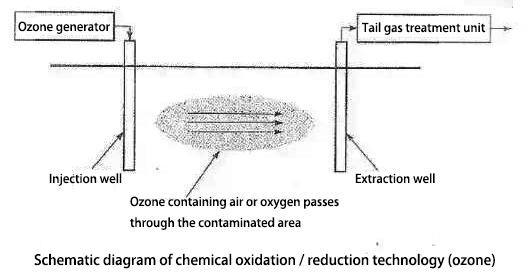

2、 Chemical oxidation / reduction technology:

Equipment: crushing and screening equipment, excavator, mixing system, persulfate and zero valent iron.

Treatment objects: heavy metals and organic pollutants.

Treatment method:

The chemicals are injected into the contaminated area, the contaminated soil is mixed with the chemicals, and the distribution and migration of pollutants and chemicals in the process of remediation and after remediation are monitored by the monitoring system.

3、 Chemical leaching technology:

Equipment: crushing and screening equipment, excavator, washing equipment, water and soil separation and dehydration equipment, sewage treatment system.

Treatment object: heavy metal or compound pollutant.

Treatment method: use a large amount of water or water solution mixed with washing AIDS, acidic or alkaline solution, surfactant and other eluent solutions to mix with the contaminated soil to elute the pollutants, and then separate the water and soil to treat the sewage.

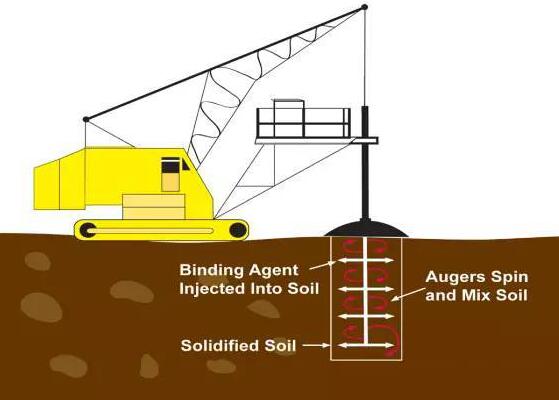

4、 Curing / stabilization technology:

Equipment: crushing and screening equipment, excavator, mixing system, soil moisture regulation equipment, adhesives, additives.

Treatment object: heavy metals.

Treatment method: the soil is pretreated and crushed (generally, the particle size of the broken soil should not be greater than 50 mm), fully mix and contact with chemicals, fix the pollutants or seal them with inert base materials.

5、 Desorption and desorption technology

Equipment: drum type thermal desorption system, composed of feed system, thermal desorption system and tail gas treatment system.

Treatment object: volatile and semi volatile organic pollutants.

Treatment mode: direct heating or indirect heating can be selected as heating mode. The soil temperature of direct heating treatment was 150-650 ℃, and that of indirect heating treatment was 120-530 ℃.

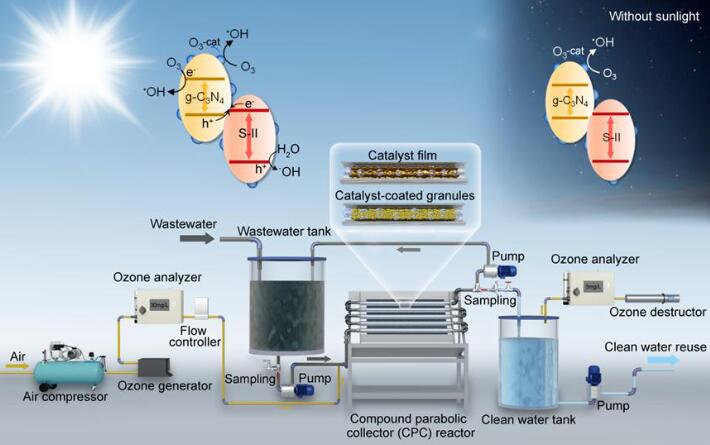

6、 Photocatalytic degradation technology:

It is used for the remediation of soil polluted by pesticides and other organic pollutants. Volatile organic compounds (VOCs) are decomposed into CO2, H2O and inorganic substances by photosensitizers (TiO2, Fe2O3, humus, etc.). It is suitable for remediation of sites with less polluted area.

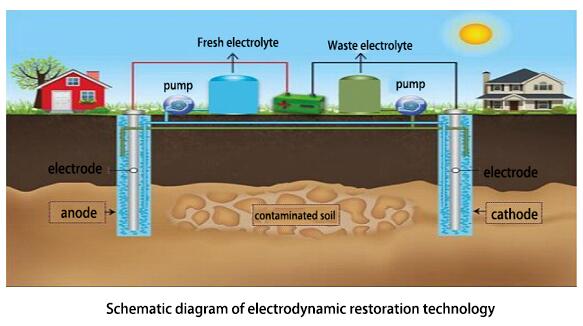

7、 Electrodynamic repair technology:

For the remediation of small-scale clay soluble organic matter contaminated soil, the combined action of electrochemistry and electrodynamics is used to drive the pollutants to accumulate in the electrode area, and then centralized treatment or separation process is carried out. No chemical input is required, and there is almost no negative impact on the environment during the restoration process.