Steam jet vacuum pump in oil refining process

Steam jet vacuum pump product description

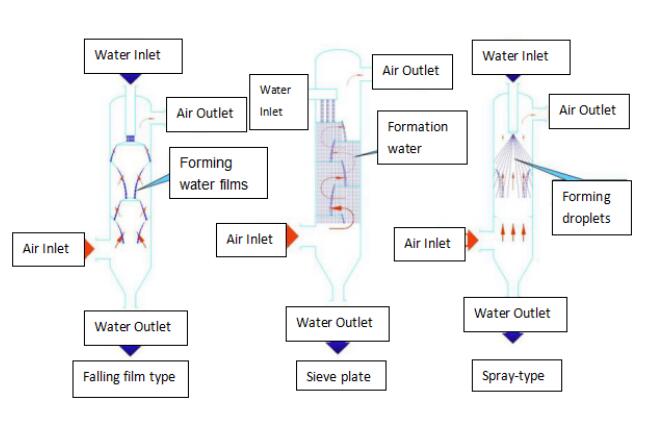

Vacuum equipment for oil refining is generally divided into one-stage jet pump (for leaching), two-stage jet pump (for dehydration), three-stage jet pump (for decolorization), and four-stage jet pump (for deodorization). It is composed of an indirect condenser. The condenser can be divided into direct spray and indirect condensation. Each has its own advantages, depending on the specific process conditions.

Condenser form 1: direct condensation type

Advantages and disadvantages of direct condensation

Advantages: low manufacturing cost

Good condensation effect

Low pressure loss

Disadvantages: pollute the environment when removing harmful substances and increase processing costs

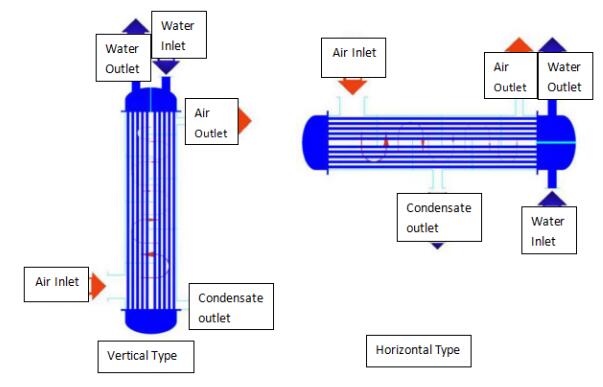

Condenser form two: indirect condensing type

Advantages and disadvantages of indirect condensation

Advantages: No pollution, environmental protection

Recyclable by-products

Cooling water can be recycled

Disadvantages:High manufacturing cost

Poor condensation effect

Easy to scale, not easy to clean

Steam Ejector vacuum pumps of requirements for the use

The quality of the power steam should be dry saturated or slightly overheated, and a filter should be added before entering the nozzle to prevent foreign matter such as welding slag from blocking the nozzle

The pressure of the cooling water should be greater than 0.2Mpa(A). If the condenser is sprayed, a filter should be installed in front of the water inlet valve to prevent hard particles from blocking the spray hole: if it is an indirect condenser, the return water pipeline should be under negative pressure Or no back pressure.

Steam ejector vacuum pump of solution

In the process of using steam jet vacuum pump, sometimes the vacuum is too long, the vacuum degree is unstable or the vacuum degree is not up to the requirements, and the cause of the fault must be found, analyzed and processed. The following failure analysis is usually performed:

(1) Whether the vacuum measuring device (including vacuum gauge, vacuum gauge, test cover) is faulty or invalid;

(2) Whether the working steam supply is normal, including pressure, temperature, dryness, hydrophobicity, fluctuations, etc., especially to check whether the reading of the pressure gauge is accurate after long-term use;

(3) Whether the circulating cooling water supply is normal, including water temperature, water pressure, water volume, water quality, etc.;

(4) Whether there is any abnormality in the production system, including system leakage, excessive gas generation in the system, performance degradation of process equipment, etc.;

(5) Whether the vacuum pump system itself is faulty, including pump system leakage, nozzle blockage or damage, increased throat diameter wear, expansion tube shrinkage section and discharge outlet fouling, atmospheric leg leakage or fouling blockage, condenser fouling blockage, Liquid accumulation in the suction pipe, etc.

The steam jet vacuum pump has large pumping capacity, wide working range, simple structure and no relative moving parts. It is a kind of vacuum equipment with a wide range of uses, mainly used in degassing, decoloring, drying, deodorizing, distillation, refrigeration and transportation. In particular, it has no selectivity for inhaled gas. It shows excellent advantages compared with mechanical vacuum pumps (oil pumps) in food production, petrochemical, oil processing, polyester production, and concentration of materials containing organic solvents.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)