Vacuum Pump Made in China

EVP Vacuum CompanyThe Co., Ltd. is a vacuum pump made in China.It is located in Shanghai and has a production base in Zhejiang province.Is a collection of all kinds of water pump research and development, production, sales, service in one of the well-known enterprises.The main products are centrifugal pumps, chemical pumps, vacuum pumps, water supply systems, etc. We have obtained import and export licenses, and have an independent foreign trade department, with an excellent professional team, to provide first-class services.To provide efficient services to foreign businessmen.At present, we have 70 pumps exported to more than 40 countries including Southeast Asia, the Middle East, Africa and Europe.

The company introduced the world‘s advanced fluid flow analysis, three-dimensional CAD, CAM, FMS and other research and development software systems, and the implementation of ERP management. It has more than 200 advanced production and testing equipments, such as the leading pump testing center, laser forming equipment, coordinate measuring machine, 12M vertical CNC lathe, etc. The products cover dozens of categories, such as construction, municipal administration, electric power, petroleum, chemical industry, mining and so on, with annual production capacity of 10 million units/set.The company has domestic first-class production equipment and precision testing equipment.Every step of the product is strictly tested to ensure that it meets the highest standards of the factory.

With the steady development of the company, the company has established a sound sales and service system to provide customers with professional technical support and services.

Main product line:

Vacuum pumps are divided into the following two categories.

Liquid ring vacuum pump

2BE series water ring vacuum pumps and compressors are high-efficiency and energy-saving products based on years of production experience and scientific research, combined with advanced international technology.They are usually used to pump solid-free particles that are insoluble in water and non-corrosive gases, thus creating pressure in vacuum or sealed containers.

It can transport corrosive gases or liquids by replacing materials.It is widely used in paper, chemical, petrochemical, light industry, pharmaceutical, food, coal, mineral processing and other industries.

Features

1.one. Imported bearings are used to ensure the accurate positioning and stable operation of the impeller.

2. The material of impeller is cast iron or welded steel, which can ensure the stability of impeller under various unfavorable conditions and greatly improve the service life of pump.

3. The pump body is made of steel to extend the service life of the vacuum pump.

4. Shaft sleeve is the most easily damaged part, made of high chromium stainless steel, the service life has been increased 5 times.

5.five. The pulley (belt drive) has the characteristics of high precision, reliable operation, long service life, convenient disassembly and so on.

6. The couplings (direct transmission) adopt standard high-strength elastic couplings, and the flexible parts adopt polyurethane materials, which are stable and reliable in operation and have long service life.

7. ‘Unique overhead air – water separator saves space and reduces noise.

8.eight. All castings are cast with resin sand.The pump has good surface quality and good cooling performance.

9. Import mechanical seal(optional) to ensure no leakage in long term operation.

10. The inner wall of the cartridge is similar to the ellipse to ensure the best exhaust effect.

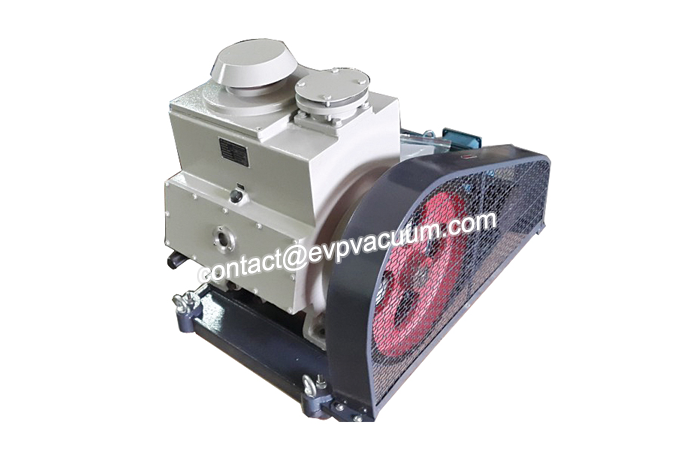

Rotary vane vacuum pump

Applications and features:

1. Start evacuation directly at atmospheric pressure.

2.two. It can not only be used as a raw oil pump, but also can be used as a support pump with other high vacuum pumps.

3.They are widely used in metallurgy, chemical, light industry, medical, electronics and LSI industries.

4. They can not be used to discharge oxygen, toxic and explosive gases and gases, and are easy to react with pump oil.Nor can it be used as a compressor or sensor pump.

5. progressive vacuum pump is one of the indispensable equipment for light industry, food, fine chemicals and plastic products.