Counter current cooling roots vacuum pump

Counter current cooling roots vacuum pump factory direct sales, enterprise management through ISO9001-2008 quality system certification

Steam suction pump (scientific name: air cooled roots vacuum pump)

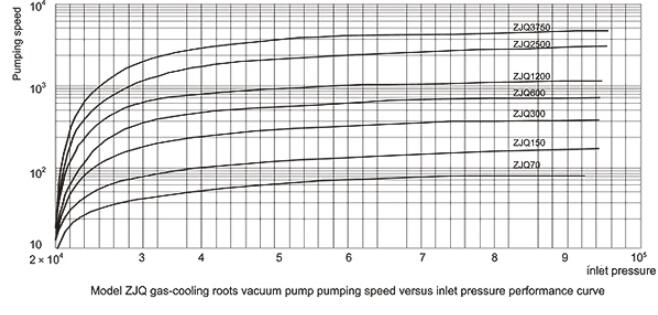

Roots pump is a non-contact double rotor rotary positive displacement pump, which is mainly composed of rotor, pump shell, pump cover, sealing device and synchronous gear. Roots pump is widely used because of its simple structure, reliable work and convenient maintenance. The position of counter current cooling port has an important influence on the performance of roots pump, and its position should not be too high or too low.

When the position is too high, due to the relationship between the pressure difference, the flow rate of the suction port may be reduced, and the reverse flow may be caused seriously. When the position is too low, it will reduce the effect of counter current cooling, although it has little effect on the air outlet. In addition, the location of the counter flow cooling port will also have a certain impact on the pulsation coefficient of the flow at the suction port, the leakage between the pump cavities, and the vibration and noise during operation.

1) Through the analysis of the velocity vector diagram and streamline diagram of the fluid in roots pump at different positions, it is concluded that the position of the counter flow cooling port has a great influence on the flow condition in the exhaust chamber. With its position moving up, the vortex flow in the exhaust chamber will be increased, and finally the flow condition in the exhaust chamber will be affected, which will cause the vortex to produce large noise. Moreover, the air leakage in the inner gap of roots pump increases gradually with the upward displacement of counter flow cold gap, which reduces the working efficiency of roots pump.

2) Under the same working conditions, with the upward movement of the counter current cooling port, the extraction flow of roots pump gradually decreases, while the exhaust flow of the exhaust port increases. The fluctuation coefficient of the flow rate at the outlet decreases with the upward movement of the counter flow cooling port, and there will be a wave fluctuation section in the descending process.

3) Through comparative analysis, it is found that when the countercurrent cooling port is between 60mm and 80mm, there is less vortex in the roots pump than that in the original position of the counter flow cooling port, that is, when the counter flow cooling port is in the original position (80mm), the speed of the leakage gas between the internal cavities is also smaller; the exhaust capacity of the suction port is improved while the exhaust volume is reduced, which can reduce the heat generation in the pump; The pulsation coefficient of the exhaust port is in the lowest position of the five cases. Therefore, when the counter flow cooling port is between 60mm and 80mm, the performance and safety of roots pump can be improved.

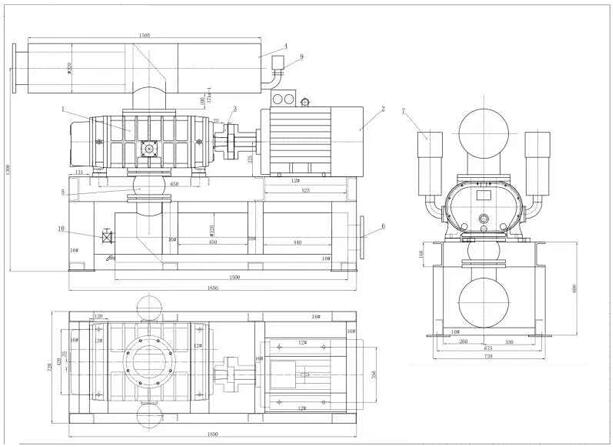

ZJQ air cooled direct exhaust roots vacuum pump series of dimension drawing