CX-100A turbo blower

Impeller in the body running without friction, do not need lubrication, so that the exhaust gas does not contain oil. It is an ideal air source for chemical industry, food industry and so on. Aluminum alloy material is used to greatly reduce the weight and achieve the purpose of lightweight; when using, the flow rate changes little with the change of pressure. Special blade design, medium pressure, medium air volume, low noise, long service life. In terms of material selection, the rotor, casing and gear ring have sufficient mechanical strength. Safe operation and long service life.

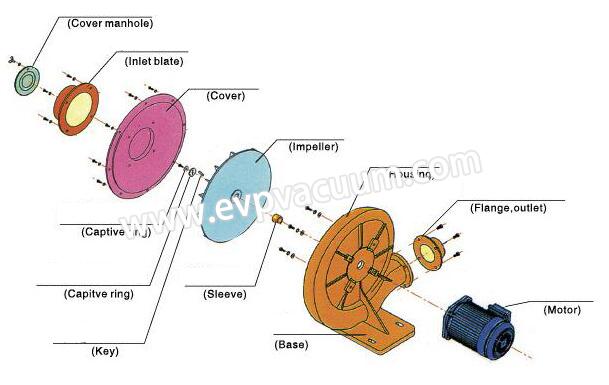

Structure

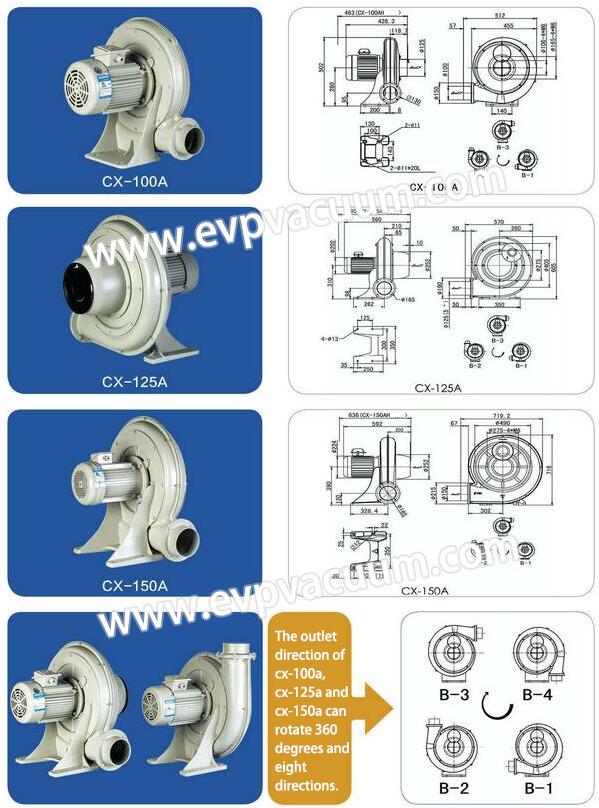

Size

CX-100A turbo blower configuration:

Motor: made according to European CE specification

Standard: use IP54, F class insulation 2-pole motor direct drive

Oil seal: use maintenance free shaft seal to separate motor from blower body

Shell: the blower and motor shell are separately cast with smooth surface and no defects.

Muffler: exhaust and suction pipes are equipped with mufflers to reduce noise

CX-100A turbo blower features:

1. High pressure, large air volume, low noise and lightweight.

2. Aluminum alloy material is used to reduce the weight and achieve the purpose of lightweight.

3. The motor is designed by i.e.c. (above 1 HP). The motor is aluminum frame motor with closed outer blower and special shaft design, which can be used for a long time.

4. Special blade design, high pressure, large air volume, low noise and long service life.

5. Special air volume regulating damper, high stability of air volume control and easy operation( CX.TB.HTB Applicable).

6. The machine type is complete, the stock is large, and the delivery is fast.

CX-100A turbo blower of application:

1, suction function: screen printing machine adsorption, welding waste gas absorption, weaving machine suction wire, photographic plate making, powder transportation, printing adsorption, industrial vacuum, vacuum dehydration, book making machine, residual cloth processing, milk carton filling machine, tofu machinery, processing material maintenance, work site, hot cloth machine, gas decomposition.

2. Blowing function: gas heavy oil spray, bottle washer blow dry, paper and cloth blowing, air knife for drying, air cushion of cutting machine, explosion gas of animal manure fermentation, auxiliary material transportation, electrolyte mixing, oxygen supply of breeding pool, taking molding products after punch press convenient stamping, powder conveying, incinerator waste discharge, flue gas blowing and drying, washing and drying, forced drying of printing machine, and drying after cleaning.