Difference between vacuum pump and air compressor

Recently, always received a message from customers asking about the difference between air compressor and vacuum pump? Take this opportunity to analyze the difference between them.

Air compressor

1. The air compressor is the main part of the air source device, which converts the mechanical energy of the prime mover into the gas pressure energy, and it is the air pressure generating device of the compressed air.

2. There are many kinds of air compressors, which can be divided into positive displacement compressor, centrifugal compressor and piston compressor.

The working principle of positive displacement compressor is to compress the volume of gas, so that the density of gas molecules in unit volume is increased to improve the pressure of compressed air;

The working principle of centrifugal compressor is to improve the movement speed of gas molecules, so that the kinetic energy of gas molecules can be converted into the pressure energy of gas, so as to improve the pressure of compressed air.

The working principle of piston compressor is to directly compress the gas and discharge it when the gas reaches a certain pressure.

3. Now commonly used air compressors include piston air compressor, screw air compressor, centrifugal compressor, slide air compressor and scroll air compressor.

Relevant people said that the selection of air compressor is mainly based on the working pressure and flow of pneumatic system. The working pressure of the air source should be about 20% higher than the maximum working pressure in the pneumatic system, because the loss along the way and local loss of the air supply pipeline should be considered. If the working pressure in some parts of the system is low, the pressure reducing valve can be used to supply air. The rated discharge pressure of air compressor is divided into low pressure (0.7-1.0mpa), medium pressure (1.0-10mpa), high pressure (10-100mpa) and ultra-high pressure (above 100MPa), which can be selected according to the actual demand. The common pressure is generally 0.7 ~ 1.25mpa.

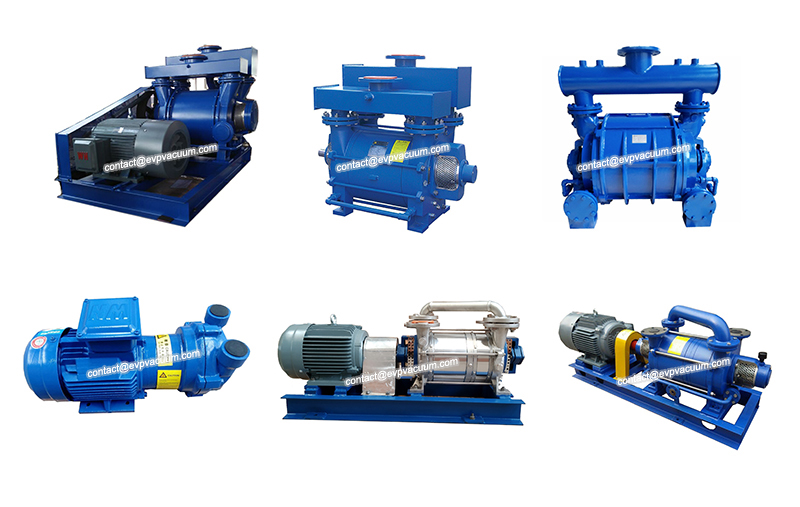

Vacuum pump

vacuum pump structure and principle:

“Vacuum” refers to the gaseous space with pressure less than 101.3kPa. Any device that can extract gas from the container and reduce the gas pressure can be called a vacuum pump. The vacuum pump commonly used in the inspection room is the oil seal mechanical vacuum pump, and the vacuum degree is generally 101 ~ 1pA. This kind of pump has a steel cylindrical stator, in which there is an eccentric steel solid cylinder as the rotor, and the rotor diameter is embedded with a sliding piece with spring. When the motor drives the rotor to rotate, the sliding piece operates in the cylindrical cavity, so that the pump cavity is separated into two areas, and its capacity cycle expands and shrinks. After the gas container to be pumped is connected to the air inlet of the pump, when the space of the pump cavity increases, the gas to be pumped is sucked in. As the rotor rotates, the gas is compressed and discharged from the exhaust port. The rotor is constantly rotating, and the process of suction, compression and exhaust is continuously repeated. The gas in the container is constantly reduced, and the air pressure is constantly reduced. The whole machine is immersed in the box containing the lubricating oil. The vapor pressure of the lubricating oil is very low, which plays the role of lubrication, sealing and cold movement.

Theoretically, the difference between vacuum pump and compressor is very small. This is different in function from the actual function in practice, because the use of pumps in industrial practice is quite different from the home use in large shopping centers. Although they depend heavily on application and usage, their efficiency is also very different and they are designed to meet different needs.

The first difference between compressors and vacuum pumps is their vacuum strength. In operation, the strength of the vacuum pump is measured by the absolute output pressure, and the smaller the result, the stronger the output power. On the other hand, the strength of the compressor is measured by the ability of the compressor to achieve high compression requirements in the fluid.

Another key difference between a compressor and a vacuum pump is the flow rate of the fluid. The flow rate of the vacuum pump depends on the pressure at both ends of the pump, and the operation principle of the compressor is to reduce the volume. Conventionally, the vacuum compressor pump allows the combined compression and discharge of the compressed fluid. An intermediate option is to use a vacuum compressor pump, which combines the two results.

Finally, the energy consumption of vacuum pump is lower than that of compressor. In terms of system functions, this helps define its efficiency. However, it should be noted that only the power consumption of the corresponding vacuum pump and compressor can be compared.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)