Diffusion Vacuum Pump Types

Diffusion vacuum pumps use high-speed steam direct injection pumps at the bottom of the pump exhaust, where the gas molecules in the throat are decomposed. In 1915, Wolfgang Gade hosted and used mercury vapor, which is a high vacuum free molecular flow in which gas molecules move better than traditional hydrodynamic diffusion understanding, regime operates pump type I. Gade used the name diffusion pump design because he found that the gas could not diffuse on the basis of the vapor flow, but would carry on with it the exhaust gas. However, the working principle may more accurately describe the gas jet pump, because diffusion plays an important role, and in other high vacuum pumps. In modern textbooks, diffusion pumps are classified as momentum transfer pumps. Diffusion pump is widely used in industry and research applications. Most modern diffusion pumps are used as working media. Cecil Reebergh discovered the possibility of using silicone oil silicone oil in 1928.

oil diffusion pump

The operation of the oil diffusion pump is a low vapor pressure oil. Its aim is to achieve higher vacuum (low pressure) by positive displacement pump only than using it is possible. Although its use is mainly related to the high vacuum range (down to 10-9 millibars), the pressure generated by today’s diffusion pumps is close to 10-10 millibars when appropriate with modern fluids and accessories. To make the diffusion pump high, ultra-high vacuum attractive is its high pumping of all gases and pumping speed per unit of low cost, speed than other types of pumps in the same vacuum range. Diffusion pumps can not be directly discharged into the atmosphere, so the front-stage mechanical pumps are usually used to maintain about 0.1 MB outlet pressure.

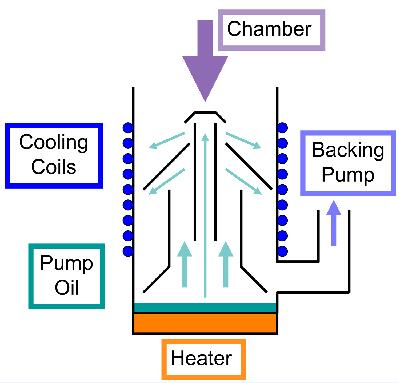

Oil Diffusion Vauum Pump Working Principle :

Boiling liquids produced by high-speed injection and guide the assembly through steam injection. In the nozzle, changes from laminar flow to supersonic speed and molecules. Usually used in fighter planes to enhance pumping operations. Diffusion vacuum pump uses external cooling or air flow or water line. Due to the influence of steam jet cooling, the diffusion pump shell outside, the working fluid is concentrated, recycled and instructed to return to the boiler. Pumping gas continues to flow into the pressure is increasing, the basis of the pump, where to compress the auxiliary front mechanical pump and exhausted environmental pressure through the outlet of the diffusion pump.

Compared with turbomolecular pump and cryopump, diffusion pump has no moving parts, so it is durable and reliable. They can operate at a pressure range of 10-10 to 10-2 millibars. They can only drive convection, which is very inefficient for energy.

One of the main drawbacks of diffusion pumps is the trend towards oil entering the vacuum chamber. Contact with hot wires or discharges on the oil-contaminated surface or inside the back chamber may result in carbon and silicon deposits. Because of reflux, oil diffusion pumps are not suitable for highly sensitive analysis equipment or other applications requiring a very clean vacuum environment, but mercury diffusion pumps may be mercury deposited in the high vacuum chamber of super cases. Usually cold traps and baffles are used to minimize backflow, although in some cases the loss of pumping capacity results.

A common mistake in operating an oil diffusion pump is in the hot oil contact atmosphere. If this happens, the burned oil will be replaced. A system should always be cooled to the atmosphere before contact at room temperature.

Steam jet vacuum pump:

Steam ejector is a popular drying method for diffusion vacuum distillation and refrigeration pumps. A steam jet pump believes that it must be removed from the steam vacuum chamber. Steam ejectors can have one or more stages, and there is no condenser inch between stages.

Compressed air jet vacuum pump:

Diffusion vacuum pumps are multi-stage compression driven jet air. This is a very popular application where the objects used are local and vacuum sucker lines moved out.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)