dry vacuum pump in space simulation

Because the volume of the container to be pumped varies from thousands of cubic meters to tens of thousands of cubic meters, the vacuum degree changes from tens of thousands of PA to several PA, and the extracted gas contains a lot of water vapor or part of nitrogen oxides, the first problem encountered in this vacuum system is the pre pumping true empty problem. If the traditional slide valve pump is used as the front stage pump, the following problems will exist:

Firstly, the slide valve pump operates for a long time under high inlet pressure. Because of the effect of air flow, the phenomenon of fuel injection is very serious; Because the extracted gas contains a lot of water vapor or nitrogen oxides, once these gases enter the pump, the vacuum pump oil will be rapidly emulsified and deteriorated, and the sealing property of the oil will be damaged, resulting in the decline of vacuum function and even the pump damage; the number of pumps required to be equipped is large, and the vibration and noise of slide valve pump are also large;

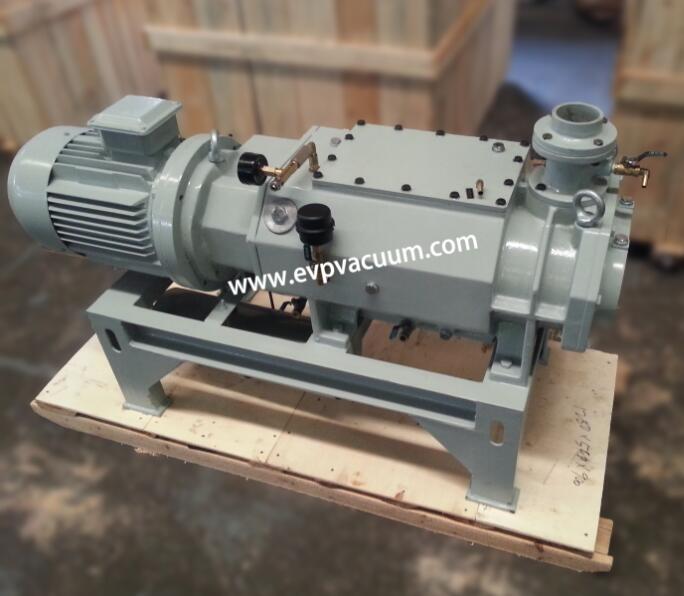

Because of its advantages of clean, oil-free, high pumping speed, small oscillation and low noise, dry-type vacuum pump has become the first choice of large-scale space simulation vacuum system at that time. In addition, in order to improve the pumping speed and limit vacuum of vacuum unit and reduce the size of screw vacuum pump, generally, a two-stage unit composed of a Roots vacuum pump and a screw vacuum pump or a three-stage unit composed of two roots vacuum pumps and screw vacuum pumps in series are selected. In order to avoid the particles from entering the pump, the inlet of the vacuum unit is equipped with an inlet filter with an accuracy of 50 μ M.

In order to avoid the particles from entering the pump, the inlet of the vacuum unit is equipped with an inlet filter with an accuracy of 50 μ M. The raw materials of solvent crystallization process are generally filtered after crystallization, which not only can not fully recover this part of solvent, but also increase the operating cost of enterprises, which will bring challenges to health, safety and environmental protection; The dry vacuum condensation system can make the organic solvent in the drying process condense at the exhaust side, complete the solvent recovery, and zero discharge of waste water and waste liquid. Because there is no other process medium in the cavity of screw pump, the internal surface adopts the anticorrosion method of coating, which is energy-saving, environmentally friendly and dry. So the dry vacuum pump is more popular in space simulation.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)