Dry vacuum pumps

1、Dry vacuum pumps introduction:

Oil free dry mechanical vacuum pump (also referred to as dry mechanical pump) refers to a mechanical vacuum pump that can start pumping from atmospheric pressure, and can discharge the pumped gas directly to the atmosphere. There is no oil or other working medium in the pump cavity, and the limit pressure of the pump is the same magnitude or close to that of the oil seal vacuum pump.

At present, most mechanical vacuum pumps used in the vacuum industry use oil, water or other polymer as the working medium of the pump, which plays a variety of roles such as cooling, sealing, lubrication, etc. With the development of science and technology and the expansion of vacuum application, there are two urgent problems to be solved in the original mechanical vacuum pump and its pumping system

First, the working medium back flow of the pump pollutes the pumped container, which in many cases affects the quality and quantity of the product and increases the maintenance cost of the equipment. Secondly, due to some reaction substances in the process of vacuum pump, the medium is seriously deteriorated, so that the pump can not work normally.

Dry mechanical vacuum pump is widely used, mainly in the following aspects:

1) Low pressure chemical vapor deposition in the polysilicon preparation process;

2) Semiconductor etching process. In these production processes, corrosive gas and abrasive particles are often used or generated;

3) In addition to the semiconductor process, some processes that produce particles do not want particles to be mixed into the pump oil. In addition to the particle discharge pump, a certain type of dry mechanical vacuum pump can meet the requirements;

4) In chemical industry, pharmaceutical industry and food industry, the distillation, drying, defoaming, packaging and so on, to prevent organic solvent pollution, suitable for dry vacuum pump;

5) It is used as the front pump of general oil-free cleaning vacuum system to prevent oil pollution.

2、 Dry vacuum pumps classification:

There are two main types of dry vacuum pump:

1) Dry screw vacuum pump

2) Oil free scroll vacuum pump

3、 Dry vacuum pumps principle:

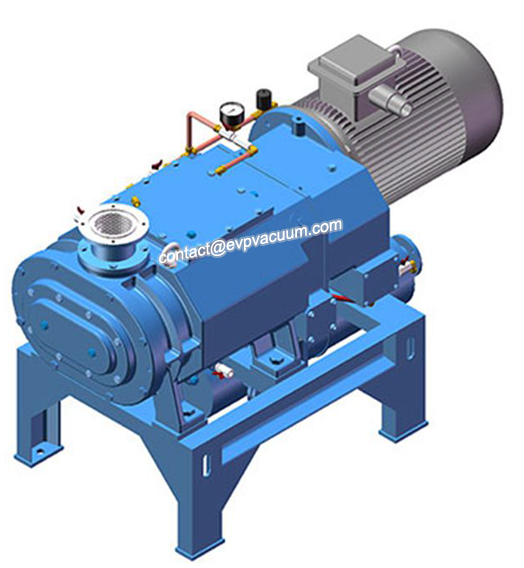

1) Dry screw vacuum pump

The dry screw vacuum pump is a suction and exhaust equipment which uses a pair of screws to make synchronous and high-speed reverse rotation in the pump housing. The two screws are supported by bearings after fine dynamic balance correction and installed in the pump housing. There is a certain gap between the screws and the screws. Therefore, when the pump is working, there is no friction between them, the operation is stable, the noise is low, and the working chamber does not need to be moistened Oil, therefore, dry screw pump can pump out gas containing a large amount of water vapor and a small amount of dust, with higher limit vacuum, lower power consumption, energy saving, maintenance free and other advantages. It is an updated product of oil seal / water ring / jet vacuum pump.

2) Oil free scroll vacuum pump

The scroll plate of a scroll oil-free vacuum pump is a scroll like structure formed by one or several involute helices connected with a plane at one end. A pair of scroll plates, composed of a static scroll plate and a dynamic scroll plate, constitute the basic suction mechanism of a vortex oil-free vacuum. for example, in a two stage scroll oilless vacuum pump, there are two fixed corresponding scroll plates, a rotating scroll plate between two scroll plates. The dynamic and static vortices move relative to each other to form a crescent shaped real cavity with constant volume change, which makes the gas inhale from the suction port, discharge from the exhaust port and complete the exhaust cycle.

4、 Dry vacuum pumps performance comparison:

1) Vacuum degree: the limit vacuum degree of dry screw vacuum pump and oil-free scroll vacuum pump is very high, and the maximum limit vacuum can reach 1-2pa;

2) Air extraction: due to internal structure problems, the oil-free scroll vacuum pump has small air extraction, which is only applicable to the process of small air extraction; the dry screw vacuum pump has complete models, which can be applied to the process of large air extraction, and can meet the needs of different customers with the help of roots vacuum pump.

3) Stability: dry screw vacuum pump has stable performance, low noise and low failure rate;

4) Special treatment: due to the flammable, explosive and corrosive gases in the process gas of chemical industry and pharmaceutical industry, the dry vacuum pump needs special treatment. The internal structure of dry screw vacuum pump is simple, two rotors and pump cavity can be treated with anti-corrosion treatment, and two kinds of coating, nickel phosphorus coating and Teflon coating, can be selected. The oil-free scroll vacuum pump is only suitable for pumping clean gas, and it can’t pump inflammable, explosive and corrosive gas.