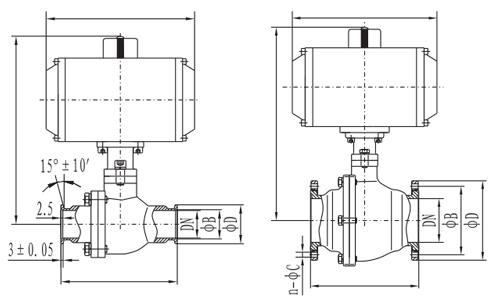

Flange ball valve

What is the operation method of flange ball valve?

Before the operation of flange ball valve, we need to be familiar with the specific use method, so how to do it? Let’s take a look at the operation of flange ball valve.

Size:

1. Make sure that the pipeline and valve have been washed before operation;

2. The operation of stainless steel ball valve drives the valve stem to rotate according to the input signal of the actuator: when the forward rotation is 1 / 4 turn (900), the valve is closed. When the reverse rotation is 1 / 4 turn (900), the valve is opens;

3. When the direction indicator arrow of the actuator is parallel to the pipeline, the valve is in the open state; when the indicating arrow is vertical to the pipeline, the valve is in the closed state.

Through the above content, I believe that we all know the operation and use method of flange ball valve.

Flange ball valve of trouble check method

Flange ball valve in the use of the process, we need to understand the failure inspection method of flange ball valve, so how to operate specifically? Let’s learn about it.

1. Inner wall of valve body. For pneumatic ball valve used in high pressure difference and corrosive medium, the inner wall of valve body is often impacted and corroded by medium, so the pressure resistance and corrosion resistance must be checked.

2. When the valve seat and pneumatic ball valve are working, the internal surface of the thread used to fix the valve seat is easy to be corroded and the valve seat is loose due to the medium penetration. Attention should be paid during inspection. For the valve working under high pressure difference, check whether the sealing surface of the valve seat is damaged.

3. The valve core is the movable part of the pneumatic ball valve when it is working. It is most seriously corroded by the erosion of the medium. During the maintenance, it is necessary to carefully check whether all parts of the valve core are corroded and worn. Especially under the condition of high pressure difference, the wear of the valve core is more serious (due to cavitation). The valve core should be replaced when it is seriously damaged. In addition, attention should be paid to whether the valve stem has similar phenomenon, or loose connection with the valve core.

4. Whether the “O” type sealing ring and other sealing gasket are aged and cracked.

5. Pay attention to whether the PTFE packing, sealing lubricating grease is aging, and whether the mating surface is damaged, and should be replaced when necessary.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)