How to Choose Roots Blower for Multi-air Pulverized Coal Burner

At present, our country’s industrial kiln industry is enduring and becoming more and more important. The operation process in the kiln industry will use multi-air pulverized coal burners such as three-air ducts or four-air ducts. In order to cooperate with the work of the pulverized coal burner with multiple air ducts, we will choose the Roots blower to supplement the work, which has reached the high efficiency of the work. The pulverized coal fan no longer uses a centrifugal fan, but chooses the current advanced three-lobe Roots blower.

The reasonable choice of Roots blower is particularly important. Everyone has an unclear understanding of the main performance parameters of a single Roots blower, resulting in the selected blower’s air volume being too large, or the booster selection is too high, or both, the motor power is too large, resulting in a serious waste of electricity , Be cautious when choosing a fan. If the actual operating current of the motor is less than 50% or about 50% of its rated current, it means that the Roots blower is selected too much. Excessive selection of Roots blowers will not only increase capital investment, but some will also waste water resources, increase operating costs, accelerate the damage to the burner nozzle, shorten the service life, and especially limit the main technical and economical aspects of the firing system The normal use of the potential of the indicators has seriously affected the economic and environmental benefits of the enterprise, and it is very unfavorable to the increase in production and consumption reduction, energy conservation and emission reduction that the country vigorously advocates. Many companies now turn a blind eye to this loss or just let it go, and haven’t paid enough attention to it.

The air volume and boost pressure of Roots blower are the two most important technical parameters. The product of air volume and boost pressure determines the power of the motor. The volume of air increases with increasing temperature and decreases with increasing pressure. When the air passes through the extrusion and friction of the Roots blower, not only the pressure will increase, but the temperature will also increase, and the volumetric flow rate will also change at this time.

The pressure increase of a Roots blower refers to the pressure that the air with a standard atmospheric pressure is sucked by the Roots blower from the inlet and then squeezed, which is the pressure difference between the outlet of the Roots blower and the inlet air, in kPa Said. Two issues must be clarified here: one is that the pressure of the Roots blower is determined by the resistance of the conveying system; the other is that the pressure of the Roots blower is used to overcome the resistance of the conveying system. For the pulverized coal conveying system, its resistance mainly includes various metering equipment, conveying pipelines and burner nozzles of the Roots blower outlet silencer.

If the air volume and pressure of the Roots blower are selected too large, it will inevitably lead to an increase in the model of the Roots blower, a waste of infrastructure investment, and an increase in power consumption; if the selection is too small, it will affect normal production.

The correct choice of the air volume of the roots blower-the determination of the secondary air volume is that the total air volume of the two or three roots blowers supplied by the pulverized coal burner should be basically the same as the required primary air volume.

The coal air volume is generally about 1/3 of the primary air volume, and its value varies in design, some are slightly larger, and some have 45%-50% of the primary air volume; some are slightly smaller, and some Choose 20%-25% of the primary air volume. If the coal air volume is selected too large, the pipeline specifications will increase accordingly. Because the air contains pulverized coal during transportation, the pipeline needs to be thickened to extend its service life and increase infrastructure costs. Therefore, the author believes that it is more appropriate to design the coal air volume as 1/3 of the secondary air volume, which can be determined according to the formula:

In Lco = 1/3, m3/min

Lco coal air volume, m3/min

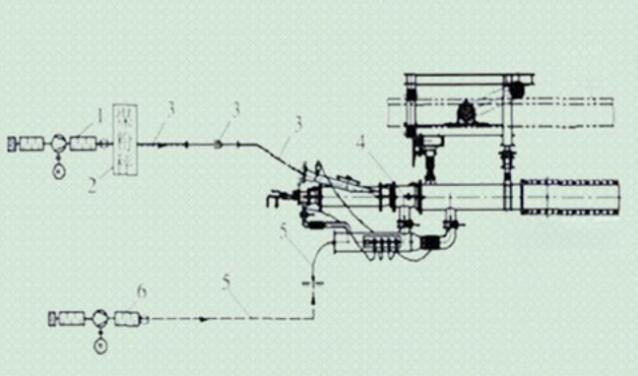

1 —A kiln head burner coal blower Roots blower outlet silencer;

2 —Pulverized coal weighing scale;

3—Pulverized coal transportation pipeline;

4 —A kiln head pulverized coal burner injection pipe;

5—Clean air delivery pipeline;

6—Kiln head burner Roots blower outlet silencer

Sketch of coal and net air conveying system for pulverized coal burner with four air ducts in the kiln

After clarifying the role of Roots blower boosting and the relationship with the resistance of the conveying system, the pressure boosting of Roots blower can be selected.

Coal blower roots blower of correct choice

If the coal is milled at the kiln head and the pipe diameters are selected to match the air volume, the resistance of the conveying system will not exceed 49kPa, no matter how large the production line is; The pipeline to be transported to the kiln head is longer, and the resistance of the transport system increases, but it will not exceed 58.8kPa. That is to say, if the coal is milled at the kiln head, it is more correct to choose 49kPa for the boost or pressure of the coal-air Roots blower. It is not appropriate to choose a high value; if the coal mill is at the kiln end, the pressure of the coal-air Roots blower is selected as 58.8. kPa is reasonable.

Clean wind roots blower boost of correct choice

There is no metering equipment in the conveying system of the clean air Roots blower, and there is no pulverized coal in the air. In addition, the reasonable design places it near the burner and the pipeline is shorter. Therefore, the resistance of the clean air conveying system is much smaller than the total resistance of the coal conveying system. In the clean air conveying system, if the motor does not use frequency conversion speed regulation, or although the frequency conversion speed regulation is installed, but does not slow down during operation, the resistance of the roots blower outlet silencer and pipeline is basically unchanged. Only the nozzle of the pulverized coal burner has different resistance due to different design schemes. The resistance of any type of pulverized coal burner will change during operation. But in any case, the resistance of the clean air Roots blower conveying system will not exceed 34.3kPa. For pulverized coal burners with an external air ejection speed of <200m/s, the resistance is smaller. Therefore, it is reasonable to select 29.4kPa for the boost pressure of the clean air Roots blower. For pulverized coal burners with an external air ejection velocity> 250m/s, the resistance will be larger. Therefore, it is reasonable to select 34.3kPa for the boost pressure of the clean wind Roots blower. In the case of a certain air volume, the higher the boosting choice of the Roots blower, the greater the power of the motor used. The smaller the ratio of actual operating current/to rated current during operation, the more unreasonable the boost selection. When the boost is too small, the power of the motor will be reduced, and overcurrent will occur during operation. If the motor has overcurrent protection, it will trip frequently. If there is no protection, it will burn the motor if it is not found in time.

In most cement production lines in my country, the choice of Roots blowers for the pulverized coal burners of rotary kilns is unreasonable. Some have a large air volume, some have a high pressure rise, and most of them have both, resulting in electrical energy. A lot of waste. However, many companies have not paid enough attention to the losses caused by this.

-Excessive secondary air volume (including coal air) is not only a waste of electricity, but more importantly, it seriously affects the main seven technical and economic indicators of the entire firing system (clinker output, quality, heat consumption, coal consumption, electricity consumption, fire Brick life, operating rate and harmful gas NOx emissions, etc.).

-The main reason for the excessive air volume of secondary air and coal is directly related to the designer and metering equipment supplier. According to the design regulations, the surplus of coal injection should be controlled within 30%. However, many designers have not designed the maximum coal injection according to the design regulations. In order to avoid liability, metering equipment suppliers often provide designers with the required air volume according to the maximum coal injection volume and the material-to-gas ratio of their own equipment. The designer also considers the principle of “Ning big, not small” when choosing Roots blower, which makes the coal blower Roots blower purchased by the user have a particularly large air volume.

-The secondary fan booster selection is too large, mainly due to the inaccurate calculation of the resistance of the conveying system of the two Roots fans for coal air and net air. If the air volume is selected reasonably, the delivery pipe specification should match the air volume of the Roots blower, and the wind speed in the pipe should not be too high. Since the local resistance of the system and the frictional resistance of the pipeline are proportional to the square of the wind speed, the coal wind speed should be controlled at 21-22m/s at 20°C, so that the coal powder will not be deposited in the tube. The reasonable wind speed of the net wind should be controlled within 15-20m/s.

This shows how important a reasonable choice of boost and air volume is.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)