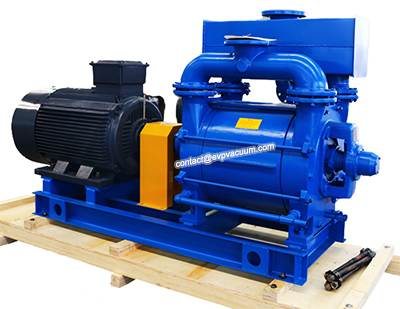

Interchangeable water ring vacuum pump

EVP vacuum pump manufacturers have successfully redesigned and developed interchangeable water ring vacuum pumps (with the same overall dimensions and connection structure, but excellent internal design) to meet customers’ increasing requirements for pump replacement (including 2BE1, 2BE3 and Cl Series).

EVP vacuum pumps and compressors are made in China. The pump does not match in size and efficiency. Each pump is assembled by hand and tested for performance, mechanical and electrical integrity. We guarantee that the manufacturing defect of the pump is 3 years, and the guarantee of vacuum, volume and horsepower is 18 months, as shown in the certified performance curve attached to each pump. Our most common pump is cast iron with a nodular iron rotor. We also manufacture 304 and 316 stainless steel and titanium and Hastelloy pumps.

EVP design improvements add years to the life of our water ring vacuum pumps and compressors. Many of our design features are unique to the industry.

The water ring vacuum pump unit is separated for easy installation and vacuumized to prevent leakage of sealing water.

The secondary bearing is a unique function of the pump and is located in the sealing area to support the shaft in the event of bearing failure and to prevent rotor / cone contact.

In order to improve efficiency, the pump has a covered pump body. This design function allows double vacuum service from a single pump. We also have 20 blade rotors that move air more efficiently than 16 blade rotors.

In order to provide maximum installation and parts inventory flexibility, water ring vacuum pumps and compressors can be directly interchangeable with other family series.

EVP has extensive experience in vacuum applications in the process industry, including the chemical, environmental, food, pharmaceutical and plastics industries. We will review your application and requirements and explain the advantages and disadvantages of each type of vacuum pump so that you can understand our recommendations. We focus on providing vacuum pump reliability for your application at a reasonable cost.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)