Jet vacuum pump in Industrial industry

Water jet vacuum pump is widely used in conveying, compression of mixed gas and steam, liquid and solid equipment, gas or liquid is often used as the power medium. Water jet vacuum pump is another very important application to produce vacuum.

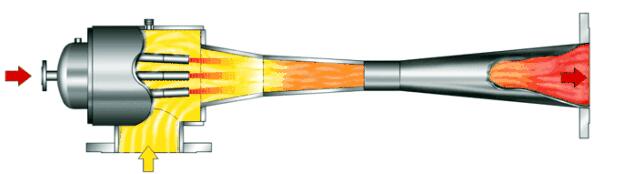

1、 water jet vacuum pump main working principle:

The main principle of water jet vacuum pump is that the power nozzle drives and accelerates the surrounding liquid, gas or solid with the liquid or gas ejected at high speed. This movement results in the mixing of the driven and driven materials. The jet velocity decreases at the diffusion point and the pressure increases. Unlike the traditional pump, water jet vacuum pump has no moving parts.

Water jet vacuum pump can be made of various materials, such as cast iron, steel, stainless steel, Hastelloy, titanium, enamel, glass, plastic and graphite, and can be made into various sizes. When the suction capacity is 1-2000000m3 / h and the suction pressure is 10-2mbar, the size can be from several centimeters to more than 30 meters.

2、 water jet vacuum pump application:

water jet vacuum pump working principle and application

(1) Because of the diversity of water jet vacuum pump, it has been widely used in various fields, such as chemical reactor, exhaust system, water treatment equipment, mixing tank, storage tank, wastewater treatment equipment, heating system, heating air supply system, power plant, swimming pool, salmon plant water supply, etc. And the formation of vacuum in different industrial fields.

(2) It is an important application field that water vapor is used as power medium to form vacuum by water jet vacuum pump. The high-speed jet transport is several times the speed of sound, so the water jet vacuum pump can easily deal with large capacity materials in vacuum.

(3) Because the single-stage water jet vacuum pump can only overcome the extremely limited compression ratio, when the suction pressure is low, several water jet vacuum pumps must be installed in series. The suction pressure of multistage steam jet vacuum pump can reach as low as 0.01mbar. In order to condense most of the power water vapor and minimize the suction of the next stage, a condenser is usually arranged between two water jet vacuum pumps. Depending on the application, use direct contact condenser or surface condenser.

(4) In the water jet vacuum pump, steam is the main power medium. In most industries, water vapor is produced in large quantities as the basic energy, so it is very easy to obtain. In the condensation process of power water vapor, more or less waste water will be produced. Although the amount is very small, and even if the cost of wastewater discharge is taken into account, the steam water jet vacuum pump is still the most economical vacuum pump, but there is always a certain negative impact on the vacuum water jet vacuum pump.

(5) Therefore, as an option, product steam is more and more used in the operation of water jet vacuum pump. For example, solvent vapor, chlorobenzene, toluene, butanediol, ethylene, glycol, furan.

(6) In this case, the power steam condenses and evaporates again to be used as the power medium. Due to the low evaporation temperature of organic steam, in most cases, this operation mode is more conducive to energy saving than using water steam operation.

(7) Another important operation range of water jet vacuum pump using product steam as power medium is that water is not allowed to be mixed in process materials. In order to obtain the best efficiency, the water jet vacuum pump using product steam as the power medium still needs to be studied in detail.

(8) Advantages of water jet vacuum pump: in terms of structure and function, this kind of water jet vacuum pump has no big difference with the vacuum water jet vacuum pump using water steam as the power medium, and has the same advantages: simple structure; safe and reliable operation without maintenance; long service life and wear resistance; corrosion resistance can be achieved by proper material selection; all materials can be manufactured. In addition, due to the recycling of condensate, there is no emission pollution.

3、 Jet vacuum pump vacuum pump is used in various industrial fields, as follows are several important application fields.

(1) The combined pump has been developed and widely used in chemical industry. The remarkable features of the pump are compact shape and double design structure. The two parallel pumps can operate alternately or independently, so it is possible to carry out maintenance without stopping.

(2) In the chemical industry, if stainless steel can not meet the requirements of corrosion resistance, ceramic / graphite vacuum water jet vacuum pump can be used to remove corrosive gas and water vapor. The water jet vacuum pump is made of ceramic and the surface condenser is made of graphite. The surface condenser is composed of a compact condenser. This structure has the advantages of small size, less space and simple field assembly.

(3) In the refinery, steam vacuum water jet vacuum pump and liquid ring vacuum pump are combined to be used in the vacuum distillation tower system of the refinery. The combination of the two pumps keeps the consumption of steam, water and electricity very low. The water vapor vacuum pump is very suitable for this purpose because it can transport a large amount of gas (in the range of 104-106m3 / h). At the same time, the operation is safe and reliable, and is not prone to failure.

(4) Similarly, the case involving gross build-up is in the vacuum generation of steel degassing. In order to produce a certain quality of steel, some processing of raw steel needs to be carried out under vacuum. This vacuum pump “vacuum pump must have two functions. One is to quickly evacuate the operating vessel to achieve the required pressure. This means that the initial pumping capacity of vacuum water jet vacuum pump must be very large (several thousand kg / h). The other is to keep the low pressure and remove a large amount of inert gas (about equivalent to several hundred kg / h at 0.6mbar).

(5) In addition, vacuum water jet vacuum pump is also used for deodorization of edible oil, polymer production of chemical compounds, desalination of sea water, dehydration of oil, conditioning of food, beverage and tobacco, suction of spinning bath and many other application fields.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)