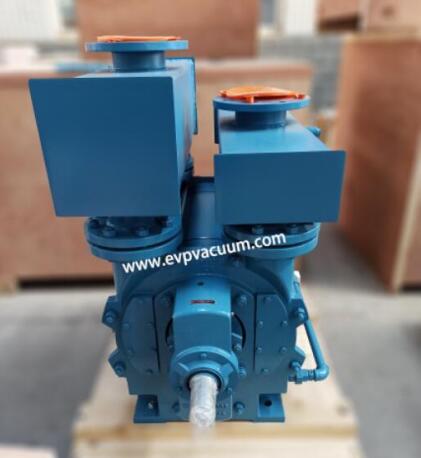

Liquid ring compressor used in coalbed methane recovery application

CBM recovery compressor (natural gas recovery)

The products provide independent solutions according to the customer’s requirements (flow/purity/pressure, use environment, main purpose and customer special requirements), from design to product tailored to customers.

Please send an email to: contact@evpvacuum.com, or click to contact us to inquire about product solutions and quotations.

Liquid ring compressor selection depends on product parameters

1.2BE series: displacement: 200m3 / h to 14400m3 / h; working pressure range: to 1.6Mpa G; (choose according to actual needs)

2.SY/2SY series: displacement: 90m3 / h to 2100m3 / h; working pressure range: 0.3Mpa G to 0.6Mpa G; (choose according to actual needs)

3.LRC series: Displacement: 90M3 / H to 2400M3 / H; Working pressure range: to 0.7 Mpa G (choose according to actual needs)

Liquid ring compressor application

Mainly used for pressurized transportation of coalbed methane (natural pipeline extraction, recovery of combustible gas and canning)

It can also be used for mixing in the pharmaceutical and brewing industries, pressurized transportation of gases in the chemical industry, blow-molded bottles in the food industry, dust removal of parts in the machine manufacturing industry, etc.

Liquid ring compressor of features

1.The product has the characteristics of low noise, low vibration, compact structure, stable operation, safe and reliable, and high level of automation. It can also be equipped with a digital remote display and control system according to customer requirements.

2.The compressor has low oil pressure, low water pressure, high temperature, low intake pressure, high exhaust pressure and other alarm and shutdown functions, which make the compressor run more reliable.

Liquid ring compressors of introduction to the structure

The unit consists of a compressor host, an electric motor, a coupling, a flywheel, a piping system, a cooling system, electrical equipment, and auxiliary equipment.

Lubrication method

The above products are all non-oil lubricated compression medium compressors

Cooling method

1.Water cooling 2. Air cooling 3. Mixed cooling (choose according to actual needs)

Overall structure

Fixed type, mobile type, skid-mounted type, soundproof cubicle type (choose according to actual needs)