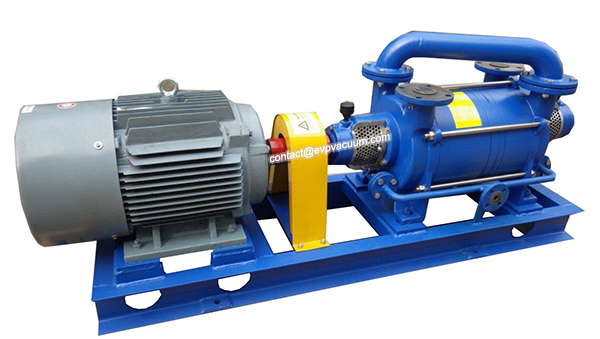

Liquid Ring Pump for Chemical Vacuum Degassing

We sell the best SK / 2SK liquid ring pump, high quality water / liquid ring vacuum degassing pump for chemical industry of Chinese manufacturer. Choosing a suitable vacuum pump for degassing may be a challenge. Used to eliminate power, semiconductor, chemical and pharmaceutical industry systems, liquid ring pumps meet these requirements.

Liquid ring pump working principle and three stages

It is necessary to fill a certain amount of working water in the pump before operation. When the pump is filled with water, when the impeller rotates, the water is driven to rotate to form a liquid ring which is tightly attached to the inner wall of the pump shell. The liquid ring and the inner surface of the impeller form a crescent shaped working space between the surface of the impeller wheel and the ends of the two sides of the cover. The space is divided into several chambers which are not connected with each other by the blades of the impeller. The volume of these chambers will increase and decrease periodically as the impeller reverses. Obviously, when the volume of the chamber becomes larger, the fluid will be inhaled, and when the volume of the chamber becomes smaller, the fluid will be kneaded and discharged. Three working stages of suction, contraction and discharge constitute a working cycle of liquid ring pump.

Take transporting gas as an example:

1) Inhalation process – when the lobes turn the right half in the figure, because the distance between the outer end of the blade and the pump shell with the pain increases, the liquid between the lobes will be thrown out, the volume of the cavity between the lobes will gradually increase, and the gas will be inhaled through the suction inlet on the side.

2) Tightening process – when the inter blade turns around the suction inlet and enters the left half turn shown in the figure, because the distance between the pump casing and the outer end of the blade gradually shrinks, the high-speed flow outside the impeller in the circumferential direction will squeeze into the inter blade. In this way, when there is no communication between the leaves and the discharge port, the gas in between is compressed.

3) Discharge process – when the inter blade turns to be connected with the discharge port, the pressure in the inter blade chamber will be balanced with the discharge pressure in an instant, and in the subsequent rolling process of the impeller, because the liquid outside the blade constantly pushes into the inter blade, and then exhausts the gas.

It can be seen that the operation principle of liquid ring pump is very similar to that of vane pump, that is to say, both of them rely on the volume change of operation chamber to attack suction and discharge, but they have important differences. The stator in the liquid ring pump is composed of a rotating liquid ring, which is composed of the kinetic energy given by the impeller to the working water. The liquid in the liquid ring gets a certain amount of energy by the impeller driving it to reverse in the right half turn shown in the figure, and is thrown into the flow channel outside the blade; and after it enters the left half turn, it can only squeeze into the inter blade and compress the gas by the kinetic energy it has obtained. In this way, the flow rate of the liquid outside the impeller must decrease with the increase of the pressure. When the discharge pressure increases to a certain value, the speed of the liquid outside the impeller will also drop to a very low level, and then it can not enter between the blades to compress the gas. That is to say, the increase of the pressure energy of the gas in the liquid ring pump in the tightening stage is completely due to the conversion of the kinetic energy obtained from the impeller by the operating water. Therefore, the discharge pressure of the liquid ring pump will not increase to the risk level with the increase of discharge load like other positive displacement pumps, that is, the operation pressure of the liquid ring pump (the pressure when the discharge valve is fully closed) is limited.