liquid ring vacuum pump classification

Liquid Ring vacuum pump classification and function

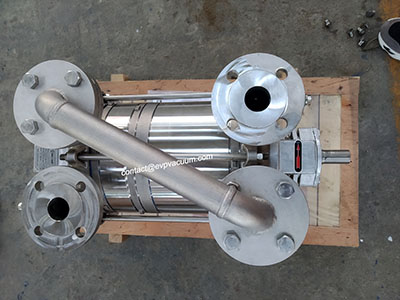

Liquid ring vacuum pump and Naxi pump are commonly used in liquid ring vacuum pump, which are mainly used for gas suction, especially when pumping corrosive gas. The water ring vacuum pump mainly rotates in the circular shell by an eccentrically installed impeller. Because there is a certain amount of water in the shell, when the impeller rotates, the water is thrown to the shell wall to form a water ring due to the action of centrifugal force.

The upper inner surface of the liquid ring is tangent to the hub, and in the front half of the rotation, the inner surface of the water ring gradually leaves the hub, so the space between the blades gradually expands, forming a vacuum and inhaling gas. In the second half of the rotation, the inner surface of the water ring is gradually close to the hub, so the gas between the blades is compressed and discharged by the water ring. Every time the impeller rotates, the volume of the blade changes, and the water between the blades moves repeatedly like a piston, pumping gas continuously.

Liquid ring vacuum pump is a wet vacuum pump, the structure is simple, compact, no valve, durable, the highest vacuum degree can reach 85%. In order to maintain the liquid seal in the pump and cool the pump body, it is often necessary to constantly fill the pump with water.

The principle of the Naxi pump is the same as that of the liquid ring vacuum pump, but because the impeller rotates in an oval shell, a two-crescent space is formed between the liquid ring and the impeller in the direction of the long axis, and the impeller repeatedly approaches and leaves the liquid ring when it rotates, and the space shrinks and expands repeatedly. In this way, the liquid can be constantly pressed out and sucked.

The liquid ring vacuum pump can make the extracted gas not in direct contact with the pump shell, so as long as the impeller is made of corrosion-resistant material when pumping corrosive gas. However, the liquid injected into the pump must not react with the gas. In this paper, water can be used when pumping air, and concentrated sulfuric acid can be used when pumping chlorine, for example, water can be used by Zade water pump in Xinjiang. It should also be noted that the liquid used should not contain solid particles, otherwise, the impeller and shell will often be worn and the pumping capacity will be reduced.