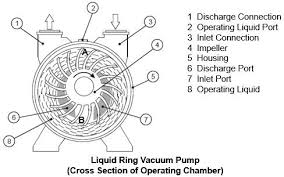

liquid ring vacuum pump disassembly and assembly

Liquid ring vacuum pumps and compressors are used to pump or compress air and other gases which are non corrosive, insoluble in water and do not contain solid particles, so as to form vacuum and pressure in closed containers. It is widely used in machinery, petrochemical, pharmaceutical, food, sugar industry and electronic fields. Liquid ring vacuum pump in the working process, gas compression is isothermal, so in the compression and suction of flammable, explosive gas, not easy to occur danger. Therefore, the application of corrosion-resistant submerged pump is more extensive.

liquid ring vacuum pump disassembly notes :

The disassembly of liquid ring vacuum pump is divided into partial disassembly, inspection and cleaning, complete disassembly, repair and replacement of parts. Before dismantling the pump, the water in the pump should be drained from the drain hole, and the pipe should be removed. All gaskets should be carefully removed during disassembly. If damaged, new gaskets with the same thickness should be replaced during assembly. The pump should be disassembled from the end without coupling in the following order.

1. Loosen and remove bearing cover.

2. Loosen the rolling bearing, screw off the round nut with hook wrench, and remove the nut on the packing gland.

3. Loosen the bearing frame from the side of the left side cover, and at the same time, turn the two removal screws (square head and cylindrical end screws) to remove the bearing and bearing bracket from the shaft.

4. Disconnect the water inlet pipe and pipe on the side cover, and loosen the connecting screw between the pump body and the side cover and the stud bolt outside the pump foot.

5. Add a cushion under the pump body, then make the side cover and the pump body away, and take down the side cover from the shaft (the shaft should be supported after the side cover is removed).

6. Make the pump body away from the cover on the other side and remove it from the shaft.

7. At this time, the working parts and parts of the pump can be inspected and cleaned. Further disassembly should be carried out in the following order.

8. Cut off the connection between the motor and the circuit, loosen the connection between the motor and the base, and separate it from the pump.

9. Remove the coupling from the shaft with a wrench and other disassembly tools.

10. Remove the key of the coupling from the shaft.

11. Remove the bearing cover. Remove the locating ring or round nut to loosen the rolling bearing.

All the above contents are about the disassembly and assembly steps of liquid ring vacuum pump. It seems that there are not many steps, but they are all closely connected. I hope this article can help you. Liquid ring vacuum pump is a kind of crude pump which uses liquid as working medium, among which water is called liquid ring vacuum pump, Other can also use oil, sulfuric acid and acetic acid as working medium, industrial liquid ring vacuum pump is mostly used.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)