liquid ring vacuum pump in oil field

With the continuous development and progress of modern industrial technology, vacuum technology has gradually been widely used in a variety of production processes. Liquid ring vacuum pump has the characteristics of compact structure, simple operation and strong adaptability to the environment, so it has a wide range of applications in actual production, whether it is mining, mineral processing, petroleum, or pharmaceutical, papermaking, power, food, or alumina plant, etc., we can see the figure of liquid ring vacuum pump in these industries.

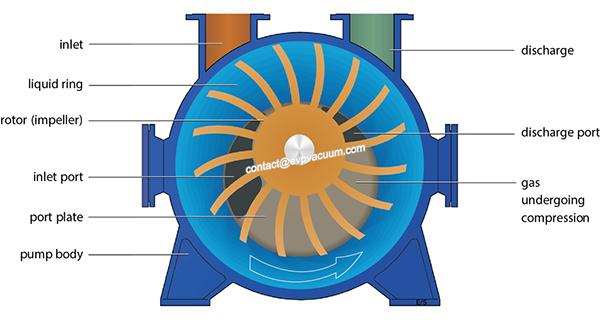

liquid ring vacuum pump working principle:

Liquid ring vacuum pump belongs to positive displacement pump, as shown in the figure below. In contrast, when the impeller is installed in the pump cavity, the gas ring will rotate along the pump cavity, so that the liquid pressure inside the pump cavity will be increased The volume of the air chamber in the exhaust area is gradually reduced, and the internal pressure rises, so as to discharge the gas.

The working fluid of liquid ring vacuum pump has two functions: one is for sealing and the other is for cooling. The commonly used working fluid is water, and other liquids suitable for the process medium, such as low viscosity oil and glycol, and other process solvents such as toluene, xylene, methanol, ethanol, propanol, butanol and ethylbenzene, can also be used.

Application of liquid ring vacuum pump in oil field

In the process of oil preparation, the process of total negative pressure evaporation is generally used to remove the solvent from the mixed oil in the leaching workshop. In recent years, the negative pressure of mixed oil evaporation and stripping in newly built oil plants is formed by liquid ring vacuum pump. The initial design of negative pressure in evaporation and stripping section of some old oil extraction plants is extracted by steam jet pump, and now it has been gradually transformed into liquid ring vacuum pump.

The limit vacuum ratio of single-stage liquid ring vacuum pump is small (up to 0.092mpa ~ 0.097mpa). The vacuum degree of the first and second evaporator is 0.040 ~ 0.053mpa, and the vacuum degree of stripper is 0.053mpa ~ 0.080mpa. Therefore, a liquid ring vacuum pump can meet the process requirements in the leaching workshop.

Decolorization and deodorization are essential sections in primary soybean oil refining. In order to avoid oxidation side reaction of oil at high temperature, decolorization and deodorization are completed under negative pressure. At present, the negative pressure of drying tank and decolorizing tower in most refining workshops is realized by liquid ring vacuum pump.

In order to save energy and reduce consumption in refining workshop, liquid ring vacuum pump has been applied to deodorization vacuum system. The residual pressure of deodorization tower is generally 133pa ~ 399pa. The single-stage liquid ring vacuum pump (up to 0.092 ~ 0.097mpa) can not meet the requirements of deodorization vacuum, and two-stage vacuum jet pump and chilled water are also needed.

With the increasing demand of energy saving and consumption reduction in oil plant, liquid ring vacuum pump is gradually applied to the vacuum system of oil plant to reduce steam consumption. However, it should be noted that in the application of liquid ring vacuum pump, on the one hand, to meet the requirements of process vacuum, on the other hand, more attention should be paid to the safe operation of liquid ring vacuum pump, especially in the leaching workshop.