vacuum pump for lithium mining

Lithium has the highest electrochemical potential among all metals, and it and its compounds exhibit a wide range of beneficial properties. Our vacuum pumps and compressors are ideal for dehydration and also contribute to the production of technical grade lithium concentrates.

Three common mineral processing methods for lithium ore

Spodumene, pyroxene and lepidolite can be used in many ways after beneficiation and concentration. The cut-off grade and industrial grade of lithium deposit are divided into manual ore and mechanical ore, and the grade index is determined respectively. According to the production practice experience, if the particle size of spodumene in the ore body is larger than 3cm, and the ore grade is more than 2% ~ 3%; if the particle size of beryl is greater than 0.5cm, and the ore grade is above 0.1% ~ 0.2%, it is suitable for manual separation, and it is divided into manual ore and the reserves of manual beneficiation are calculated. The tailings of manual ore with mechanical separation value and not suitable for manual separation belong to mechanical separation ore.

The mineral processing methods of lithium ore include manual separation, flotation, chemistry or chemistry_ Among them, the first three methods are commonly used.

The vacuum pump for lithium ore is introduced below. For more information, please click to contact us.

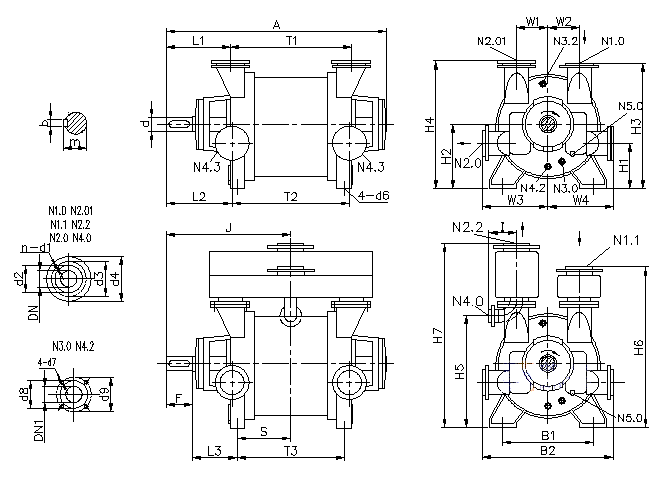

2BE1 pump head of installation dimensions

N1.0 inlet flange n1.1 connecting pipe flange n2.0 exhaust end flange n2.01 upper exhaust flange

N2.2 separator flange n3.0 working fluid interface n3.2 stuffing box sealing liquid interface

N4.0 separator drain n4.2 flushing, drain n4.3 leakage discharge n5.0 automatic relief valve

|

Codename

|

A

|

B1

|

B2

|

b

|

DN1

|

d

|

d6

|

d7

|

d8

|

d9

|

F

|

H1

|

H2

|

H3

|

H4

|

H5

|

H6

|

|

|

2BE1 303

|

1580

|

670

|

1010

|

28

|

25

|

100

|

35

|

M12

|

68

|

85

|

165

|

335

|

475

|

910

|

935

|

825

|

1185

|

|

|

2BE1 305/306

|

1690

|

670

|

1010

|

28

|

25

|

100

|

35

|

M12

|

68

|

85

|

165

|

335

|

475

|

910

|

935

|

825

|

1185

|

|

|

2BE1 353

|

1745

|

800

|

1160

|

32

|

32

|

120

|

35

|

M12

|

78

|

100

|

165

|

395

|

560

|

1050

|

1080

|

930

|

1370

|

|

|

2BE1 355/356

|

1885

|

800

|

1160

|

32

|

32

|

120

|

35

|

M12

|

78

|

100

|

165

|

395

|

560

|

1050

|

1080

|

930

|

1370

|

|

|

Codename

|

H7

|

I

|

J

|

L1

|

L2

|

L3

|

m

|

S

|

T1

|

T2

|

T3

|

W1

|

W2

|

W3

|

W4

|

N3.2

|

N4.3

|

|

|

2BE1 303

|

1360

|

205

|

875

|

430

|

443

|

315

|

106

|

395

|

890

|

864

|

790

|

230

|

230

|

480

|

505

|

G1/2″

|

G1/2″

|

|

|

2BE1 305/306

|

1360

|

205

|

930

|

430

|

443

|

315

|

106

|

450

|

1000

|

974

|

900

|

230

|

230

|

480

|

505

|

G1/2″

|

G1/2″

|

|

|

2BE1 353

|

1570

|

245

|

955

|

430

|

455

|

335

|

127

|

455

|

1050

|

1000

|

910

|

285

|

285

|

555

|

580

|

G1/2″

|

G1/2″

|

|

|

2BE1 355/356

|

1570

|

245

|

1025

|

430

|

455

|

335

|

127

|

525

|

1190

|

1140

|

1050

|

285

|

285

|

555

|

580

|

G1/2″

|

G1/2″

|

|

|

Codename

|

DN

|

d1

|

d2

|

d3

|

d4

|

n

|

Codename

|

DN

|

d1

|

d2

|

d3

|

d4

|

n

|

|||||

|

2BE1 303

2BE1 305 2BE1 306 |

N1.0

N2.01 |

150

|

22

|

212

|

240

|

285

|

8

|

2BE1 353

2BE1 355 2BE1 356 |

N1.0

N2.01 |

200

|

22

|

268

|

295

|

340

|

8

|

|||

|

N1.1

N2.2 |

200

|

22

|

268

|

295

|

340

|

8

|

N1.1

N2.2 |

250

|

22

|

320

|

350

|

395

|

12

|

|||||

|

N2.0

|

125

|

18

|

188

|

210

|

250

|

8

|

N2.0

|

150

|

22

|

212

|

240

|

285

|

8

|

|||||

|

N4.0

|

100

|

18

|

158

|

180

|

220

|

8

|

N4.0

|

125

|

18

|

188

|

210

|

250

|

8

|

|||||

Vacuum pump equipment selection of understand the knowledge

From the aspect of production, we can notice that the vacuum pump is often a very important equipment, and when we pay attention to this kind of equipment, we can notice that only when we choose the right product in production, can we give better guarantee to each part of the production. Therefore, we hope that every friend can better grasp these basic information, and only in each part can we have a clear understanding Only after that can we find the right answer.

When paying attention to the selection of vacuum pump equipment, it is very important whether the vibration will affect the environment and process in the specific working process, and people should better understand these contents. In the case of air evacuation, the specific gas composition is also very important, and has a direct relationship with the use of safety. Of course, in the case of strengthening the working pressure, it is very important to be able to exhaust all the gas in the process.

Of course, it is also very important in the combination. More appropriate scheme should be adopted in combination. The specific pollution requirements should also meet the relevant national safety standards. Of course, the price of the pump itself, the cost of maintenance in the process of use and the consumption in the process of operation are very important, so we should better grasp these contents.

I hope that when purchasing vacuum pump, we can know clearly from each part. Only when we can master each factor better, can we finally find a more ideal answer. The specific removal of gas is also very important for whether there is pollution in the environment, because the overall environmental protection requirements in the production process should also become very important information, which should be better grasped in the production process.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)