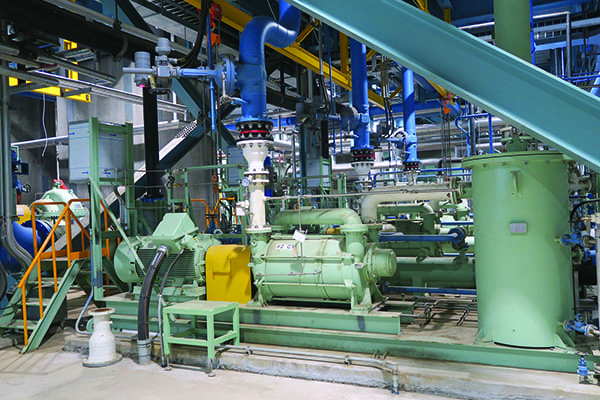

Mechanical vacuum pump system in steel making industry

Abstract: in the process of high-quality steel smelting, vacuum refining technology is widely used in the steel-making process. Due to the constraints of environmental protection and production cost, the mechanical vacuum pump system has the characteristics of low operation cost, temperature control and excellent effect, so the steel industry began to prefer the mechanical vacuum pump system. Therefore, this paper studies the application of vacuum pump system in steel-making industry, trying to provide effective feasible suggestions for it.

1. Vacuum pump for refining

At present, the main vacuum pumps used in the refining furnace of steel-making production line are steam jet pump and mechanical vacuum pump. The steam jet pump is a kind of device which uses the steam fluid as the extraction medium to obtain the vacuum. When the steam flows through the Laval nozzle, the pressure energy is converted into kinetic energy, and then a negative pressure area is formed. The extracted gas is sucked into the mixing chamber, and the kinetic energy of the working steam converted from the pressure energy is transferred to the extracted gas. The steam jet pump system has been widely used because of its large pumping capacity, high reliability and low cost. In recent years, the phenomenon of electricity price and steam price inversion has appeared in the domestic market, and the mechanical vacuum pump system has gradually entered the field of vision of the steel plant. Common mechanical vacuum pumps include reciprocating mechanical pump, roots mechanical pump, turbine mechanical pump, etc.

2. Introduction to mechanical pump

The mechanical pumps commonly used in steelmaking process are oil seal vane vacuum pump, roots mechanical vacuum pump and screw mechanical pump. Roots mechanical pump is generally used as the main pump of vacuum system. The utility model uses a pair of 8-shaped rotors to maintain a certain clearance in the vacuum pump shell and to rotate in the opposite direction at the same speed to produce the effect of suction and exhaust. The two rotors are supported in the rolling bearings of the two side end caps in the vacuum pump housing. Depending on a pair of adjustable synchronous gears, the two rotors always maintain a certain mutual position when rotating in reverse direction at high speed, thus completing the process of suction and exhaust.

Screw pump is a variable volume vacuum pump which uses the change of vacuum pump cavity volume to achieve suction, compression and exhaust. The pump body is sensitive to the temperature of the pumped gas, so it needs to be equipped with an efficient gas cooler before the vacuum pump. At the same time, the vacuum pump body has a high requirement for the cleanliness of the extracted gas, so it needs to be equipped with an efficient dedusting system in front of the pump. The function of the dedusting system is to reduce the dust content of the high temperature dusty gas produced by the vacuum tank or the molten steel in the vacuum tank by about 80%, so that the large particle dust can be effectively removed, so as to meet the requirements of the vacuum pump group for the dust concentration. The first stage pump can be started under normal atmospheric pressure to complete the function of pre vacuum pumping. After reaching a certain degree of vacuum, the second stage pump and the third stage pump can be started respectively to gradually reach the second and third stage vacuum degrees, so as to achieve the purpose of vacuum pumping.