Dry screw vacuum pump

Dry screw vacuum pump is mainly using a pair of screw, characterized by two screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the dry screw vacuum pump is working, no friction between each other, smooth running, low noise, working cavity without lubricating oil, dry screw pump can pump in addition to containing a large amount of water vapor and a small amount of dust gas occasions, limiting vacuum is higher.

The dry screw vacuum pump, which USES a pair of screws, is used in the pump case for the synchronous high-speed reverse rotation of the suction and exhaust gas extraction equipment. Its advantages make up for the shortage of oil sealed vacuum pump, we all call it the upgrade version of oil sealed vacuum pump. But the cost of dry screw vacuum pump is also its deficiency. Next, I will introduce its advantages and disadvantages.

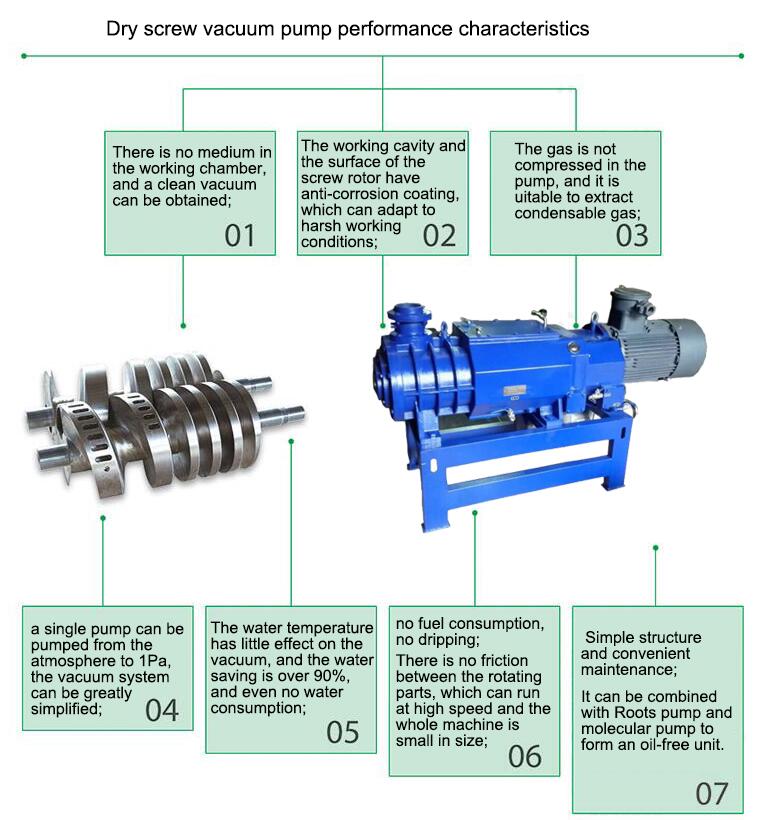

The advantages of dry screw vacuum pump:

1. The working chamber and screw rotor surface have anti-corrosion coating, which can adapt to the bad working conditions.

2. The gas is not compressed in the pump, suitable for extraction of condensable gas.

3. No oil, no drip.

4. Simple structure and convenient maintenance.

5. The pumped gas directly educates the pump body, does not pollute water, has no environmental pressure, and gas recovery is more convenient.

The disadvantages of dry screw vacuum pump:

1. Since the screw pump is difficult to process and is a new product, the price is very high.

2. Not suitable for extraction of explosive gases.

3. It is not suitable to extract gas containing excessive oxygen.

Product display

Technical Parameters

| Model | Unit | LG50~LG350 | |

| Suction Capacity | 50 Hz | m³/hr | 180~1260 |

| 60 Hz | 216~1512 | ||

| Ultimate Pressure | 50 Hz | mbar | 0.02 |

| 60 Hz | 0.01 | ||

| Motor power | 50 Hz | Kw | 5.5~22 |

| 60 Hz | 7.5~ 26 | ||

| Rotary Speed | 50 Hz | RPM | 2900 |

| 60 Hz | 3550 | ||

| Inlet diam | mm | 50~100 | |

| Outlet diam | mm | 40~ 65 | |

| Lubricating oil consumption | L | 0.85~2 | |

| Cooling water consumption | L/min | 2.5~4 | |

| gal/min | 0.67~1.07 | ||

| Weight | Kg | 295~850 | |

| Noise | dB(A) | 68~84 | |

| Working temperature | ℃ | 5~40 | |

| Max. Permissible humidity | / | 90% | |