Oil-free rotary vane vacuum pumps

Product details:

The 6p motor is used with low speed of 965r / min

More stable operation, low noise and longer service life

Large flow design, exhaust capacity up to 1500 L / min

Motor power: 2.2kw

Displacement: 700L / min

Limit vacuum degree: 90kpa

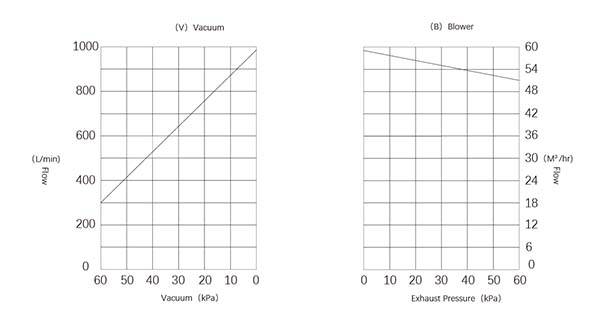

Performance curve

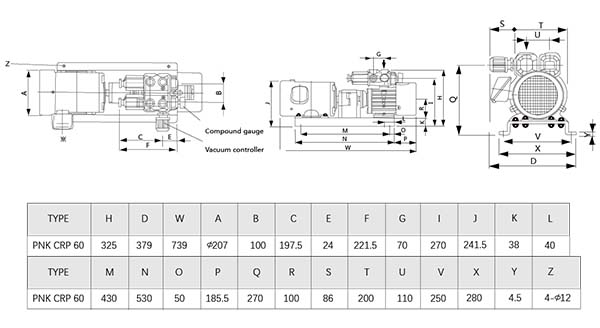

Installation dimensions

Oil free rotary vane vacuum pump features:

1. Because it is oil-free, it does not contain oil when using vacuum and exhaust, which will not cause oil pollution to the working environment and products.

2. Low operating noise (low harsh sound even at the same decibels due to the elimination of the annoying high cycle Boeing) and long service life. At the same time, it is equipped with vacuum pressure gauge and pressure regulating control valve.

3. Because the composite pump is a double cylinder, it has dual functions (vacuum pump and blower are in parallel). It can be used as a vacuum source with a vacuum degree of 60kpa and an air source with an exhaust pressure of 60kpa at the same time.

4. Compared with other similar vacuum pumps, the pump has the advantages of small volume, light weight and easy operation.

5. 50 Hz / 60 Hz universal, suitable for most parts of the world power supply and voltage.

Oil-free rotary vane vacuum pump of installation and use

1. The vacuum pump should be installed in a solid place with sufficient space around for inspection, maintenance and maintenance.

2. Under the base of the vacuum pump, the foundation level should be kept. At the four corners of the base, cushion rubber or bolt should be installed to ensure that the vacuum pump works smoothly and vibrate.

3. The connecting pipe between vacuum pump and system shall be sealed reliably. Metal pipeline connection can be used for small vacuum pump, oil resistant rubber shall be used for sealing gasket, and vacuum rubber pipe can be used for small vacuum pump connection. The pipe diameter shall not be less than the suction diameter of vacuum pump, and the pipeline shall be short with few elbows. (the welding slag in the pipe should be removed when welding the pipeline, and it is forbidden to enter the vacuum pump cavity.)

4. In the connecting pipeline, the user can install a valve and a vacuum gauge above the air inlet of the vacuum pump to check the limit pressure of the vacuum pump at any time.

5. Connect the power supply and ground wire according to the motor label, and install fuse and thermal relay with appropriate specifications.

6. When the vacuum pump is put into operation, the vacuum pump must be turned on in order to prevent the vacuum pump from being turned on. (turn in the direction indicated by the shield)

7. For the vacuum pump with cooling water, connect the cooling water according to the regulations.

8. If a solenoid valve is installed at the vacuum pump port, the valve and the vacuum pump should act at the same time.

9. When the gas discharged from the vacuum pump affects the working environment, the pipeline can be installed at the exhaust port to lead away or install the oil mist filter.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)