Oil refining large capacity vacuum booster pump

Refining is a process that distills crude oil or other oils and fats without changing the molecular structure. In the process of petroleum refining, crude oil must go through a series of processing processes to obtain various useful petroleum products. It generally refers to petroleum refining, that is, cracking crude oil into kerosene, gasoline, diesel oil, heavy oil and other fuels that meet the requirements of internal combustion engines, and produce chemical raw materials, such as olefins and aromatics. Nowadays, refineries are generally oil-chemical combined refineries.

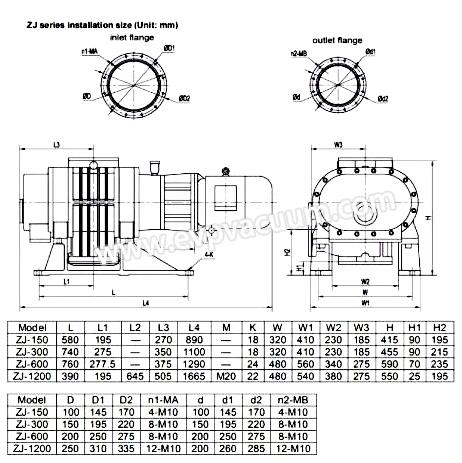

The following is to introduce the large capacity vacuum booster pump used in oil refining:

|

Model |

ZJ-150 |

ZJ-300 |

ZJ-600 |

ZJ-1200 |

|

|

Pumping speed(L/s) |

150 |

300 |

600 |

1200 |

|

|

Ultimate pressure(Pa) |

5×10-2 |

||||

|

Max. allowable diff. pressure(Pa) |

8×103 |

5×103 |

|||

|

Motor rotary speed(RPM) |

3000 |

||||

|

Suitable motor power(kW) |

2.2 |

4 |

7.5 |

11 |

|

|

Flange size |

Inlet(mm) |

100 |

150 |

200 |

250 |

|

outlet(mm) |

100 |

150 |

200 |

200 |

|

|

Cooling water consumption(L/h) |

120 |

150 |

|||

|

Allowable temperature(℃) |

100 |

||||

|

Vacuum pump oil |

100# |

||||

|

Weight(without motor)(kg) |

195 |

250 |

760 |

860 |

|

Size:

Components:

Vacuum booster pump is composed of vacuum system and hydraulic system, which is the pressurization device of hydraulic braking system. Usually, the auxiliary cylinder, the vacuum servo chamber and the control valve are assembled into one component, which is the core component of the vacuum booster servo braking system. The difference between the vacuum booster pump and the vacuum booster pump is that the vacuum booster pump is located between the brake pedal and the brake master cylinder, which is used to increase the driver’s stepping on the master cylinder; while the vacuum booster pump is located in the pipeline between the brake master cylinder and the slave cylinder, which is used to increase the output oil pressure of the master cylinder and increase the braking effect. A kind of

Fault analysis:

Simple test method for performance of vacuum booster pump:

① Step on the brake pedal when the engine is not working. When the brake system has a certain pressure, that is, when the brake height is relatively stable, start the engine. At this time, the vacuum booster pump starts to work, and the vacuum chamber appears empty. The pressure difference between the two chambers of the afterburner cylinder causes, the foot should move forward slightly, and the pressure in the hydraulic braking system is increased. If the pedal does not move forward, it indicates that the vacuum is in There is a problem with the booster pump.

② Start the engine for about one minute, step on the brake pedal, and then stop the engine. The pedal height rises within half a minute, which indicates that the pressure difference between the two chambers of the afterburner cylinder disappears too quickly. The sealing performance of the vacuum booster pump is poor. It should be overhauled.

③ When starting the engine, the air valve in the control valve of the vacuum booster pump should still be closed when the brake pedal is not stepped on, and the vacuum valve is open. Use a thin piece of paper close to the air filter. If the paper is attracted, it means that the air valve is not closed tightly and should be overhauled

④ Remove the vacuum pipe from the vacuum booster pump and cover the pipe orifice with a piece of paper. Start the engine. If the vacuum pipe orifice has little or no attraction to the paper, it indicates that the vacuum pipe is leaking or blocked.