Positive displacement vacuum pump

The positive displacement vacuum pump is a large class of vacuum pumps. The liquid ring vacuum pump which is the main product of EVP vacuum pump manufacturer is one of the positive displacement vacuum pumps. At the same time, it also includes 2BV liquid ring vacuum pump, 2be liquid ring vacuum pump, DVL liquid ring vacuum pump, Cl liquid ring vacuum pump and other vacuum pumps. What are the principles and characteristics of so many vacuum pumps? Let EVP vacuum pump manufacturer tell you.

Liquid ring vacuum pump is called liquid ring pump for short. Because the working medium is mostly water, it is also called water ring vacuum pump directly in many times. It is a kind of crude vacuum pump. For users, the limit vacuum degree of liquid ring vacuum pump is not very important, it is related to the working fluid of liquid ring vacuum pump. Isothermal compression and extractable flammable and explosive gas are the most important characteristics of liquid ring vacuum pump.

liquid ring vacuum pump basic types and structure:

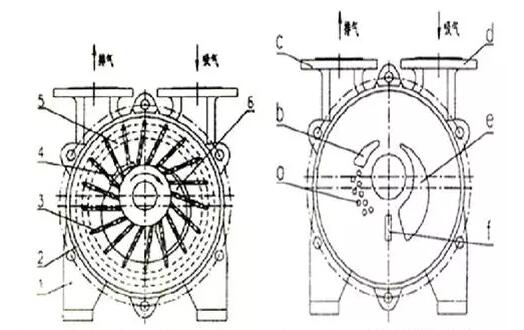

Liquid ring vacuum pump can be divided into single-stage single action, single-stage double action, double-stage liquid ring vacuum pump and gas injector + liquid ring vacuum pump unit according to different structures, which are mainly several types. The two-stage vacuum pump is mainly composed of a single-stage vacuum pump in series. We take the single-stage single acting liquid ring vacuum pump as an example to illustrate that its main structure consists of pump body, end cover and impeller. In details, it is composed of impeller, rubber ball, liquid ring (water ring), pump body, suction port, exhaust port, etc.

liquid ring vacuum pump working principle:

Liquid ring vacuum pump is equipped with working liquid in the pump body. When the impeller rotates in a clockwise direction, the working fluid is thrown around by the impeller. Due to the centrifugal force, the liquid forms a closed ring of approximately equal thickness, which is determined by the shape of the pump cavity, namely the liquid ring. The upper part of the liquid ring is tangent to the impeller hub, and the lower inner surface is in contact with the top of the blade (the blade has a certain insertion depth in the liquid ring). Due to the eccentric installation of the impeller, a crescent shaped space is formed between the impeller hub and the liquid ring during the working process. This space is divided into several small cavities with the same number of blades by the impeller. The volume of each cavity changes periodically with the rotation of the impeller.

If the upper 0 degree of the impeller is taken as the starting point, the volume of the small cavity will increase from small to large when the impeller is 180 degrees before rotation, and it is connected with the suction port at the upper end. At this time, the gas will be sucked in, and the small cavity will be isolated from the suction port when the suction is finished. When the impeller continues to rotate, the small cavity will be reduced from large to small, so that the gas will be compressed. When the small cavity is connected with the exhaust port, the gas will be excluded from the pump. Such a periodic cycle completes the process of pumping gas.

liquid ring vacuum pump characteristics:

After the introduction of EVP vacuum pump manufacturer, I think you have a preliminary understanding of the structure and principle of liquid ring vacuum pump. What are its characteristics?

Liquid ring vacuum pump was first used as a self-priming pump, and then it was widely used in many fields, such as petroleum, chemical industry, because of its isothermal compression, as well as its ability to pump out flammable, explosive, dust containing and water containing gases. Its advantages include:

1. The structure is simple, the manufacturing accuracy is not high, and it is easy to process;

2. With compact structure and high revolution, it can be directly connected with the motor without any reduction device, so it can obtain large displacement with small size. The pumping speed range of liquid ring pump is 10-25000m3 / h;

3. The compressed gas is basically isothermal compression;

4. There is no metal friction surface in the cavity, so there is no need to lubricate the pump, so the wear is small;

5. Suction uniformity, stable operation, simple operation and convenient maintenance;

However, the liquid ring vacuum pump also has its limitations:

1. Low efficiency, high power consumption, generally around 30%, better up to 50%.

2. High limit pressure and low vacuum. The vacuum degree of liquid ring vacuum pump is not only limited by its structure, but also by the saturated vapor pressure of working fluid. The vacuum degree of water medium is between 2000-4000pa, and that of oil medium is 130pa.

3. Pollution. The working liquid of liquid ring vacuum pump (water is common) will be discharged out of the pump together with the gas in the working process, causing pollution, and it must be continuously supplemented.

This is the introduction of liquid ring vacuum pump in positive displacement vacuum pump. I believe that under the introduction of EVP vacuum pump manufacturer, you have a direct understanding of liquid ring vacuum pump. If you want to know more about positive displacement vacuum pump, please feel free to consult us.

Positive displacement vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)