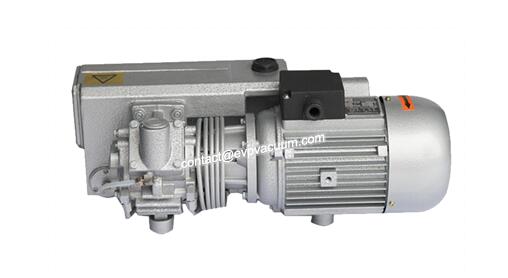

Rotary vane vacuum pump water absorption process

Rotary vane vacuum pump is used for vacuum water absorption process in concrete construction

The rotary-vane vacuum pump suction is a kind of concrete mechanical dewatering method, rotary vane vacuum pump in the practical application of concrete construction can effectively control the surface shrinkage crack, improve the frost resistance, reduce the water cement ratio, shorten the leveling, plaster, hair, ripping process clearance time, accelerate the template turnover, improve construction efficiency, reduce labor intensity, to create conditions for concrete mechanical construction. Road engineering asphalt concrete, cement concrete and other types of pavement work is calculated by multiplying the design length by the design width (including turning area), not deducting the area occupied by various Wells.

At present, high-rise concrete pumping is widely used in civil construction, pumping concrete collapse degree, cement slurry, construction often appear cracks, civil construction period requirements are very tight, high quality requirements, in order to meet the requirements, the project, the use of rotary vacuum pump water absorption process, can achieve good results.

What is the forming principle of rotary vane vacuum pump used in vacuum water absorption process?

Vacuum water absorption and absorption process, is to use more fluidity of commercial concrete, pouring into the mold, and then use rotary vacuum pump for water absorption, with the help of atmospheric pressure and vacuum chamber pressure difference, the discharge of commercial concrete mix in the excess water and gas.

In the process of vacuum treatment, a vacuum is formed in the vacuum chamber on the surface of commercial concrete. The degree of vacuum is expressed by vacuum, with pa as the unit. With the extension of the time of vacuum treatment, part of the excess water and air in the commercial concrete are discharged, the solid particles are close to each other, the water continues to be squeezed and filtered, the cement slurry is concentrated, the water-cement ratio is reduced, and the density of commercial concrete is continuously improved. The residual water-cement ratio of commercial concrete treated with vacuum water absorption is no less than 0.3, which will not affect the normal hydration of cement.

Through the application of water absorption technology of rotary vane vacuum pump in engineering, it is found that this technology has the following characteristics:

1. Speed up construction. The vacuum absorbent commercial concrete adopts the mixture of fluidity commercial concrete with large collapse rate, and its pouring, spreading and vibration time is short and easy to operate. Vacuum water absorption can be immediately wiped smooth, shorten the quiet time, reduce the influence of season and climate conditions, can shorten the construction period.

2. Improve the quality of floor components. Adopting the floor slab with vacuum water absorption technology, the commercial concrete is compact, high strength, uniform material, beautiful appearance and quality assurance. In addition, the ultimate flattening, compaction and pulping have greatly improved the wear resistance, permeability and crack resistance of the surface of commercial concrete.

3. Improve working conditions. The machine is used to smooth, compress and smooth, instead of manual operation, which reduces labor intensity and improves efficiency. Because of the use of mobile commercial concrete, avoid long time strong vibration, reduce noise, improve the working environment and operating conditions.

4. Save raw materials, reduce engineering costs. Compared with ordinary production process, the cost of vacuum water absorption equipment is increased, but the cost of template rental is reduced. Fast construction speed, can greatly reduce the production cost.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)