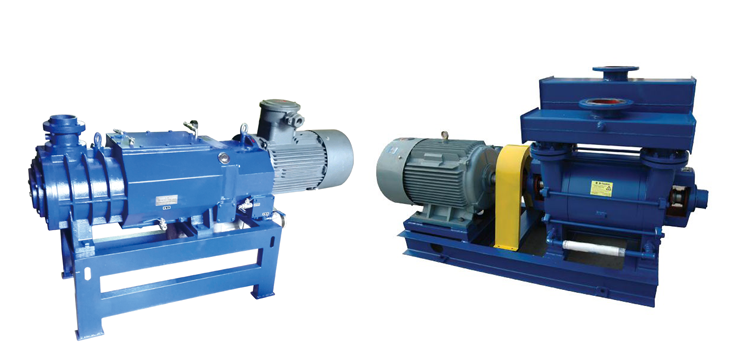

Screw vacuum pump and liquid ring vacuum pump comparison between

| Pump type | Dry screw vacuum pump | Liquid ring vacuum pump |

| The working principle | The two rotors and the housing form several Chambers and realize gas compression. The rotor rotates inward in opposite directions, and these Chambers “move” from the inlet of the pump to the exit side in a regular manner, so that the gas is transported out in the form of low whirlpool flow, realizing the process gas extraction process | The pump body is driven by the liquid ring, and the inhaled gas at the gas inlet is mixed with the liquid ring |

| Structure | Screw vacuum pump by the rotor, housing, gear box, water – cooled sleeve and other parts | Liquid ring vacuum pump by the pump shaft, impeller, impeller, shell, vapor-liquid separation tank, heat exchanger, pipeline pump and other parts |

| Vacuum | Screw vacuum pump no matter how much steam content in the process gas, can maintain a good vacuum (suction working pressure level: atmospheric pressure ~1Torr) | Due to the temperature change of working fluid in summer, the vacuum is unstable, and the suction working pressure level is 60Torr |

| Extreme pressure | Ultimate pressure of single screw vacuum pump: 5~50Pa | The limit pressure of a single liquid ring pump is about 3300Pa earlier, which is related to the type of working liquid medium and working liquid temperature.

If you want to achieve a better limit vacuum needs to be used with roots pump |

| Swept volume | The working pressure is allowed to be high (atmospheric pressure is 10Pa), the pumping volume is large up to 2700 cubic meters per hour, the relative pumping volume is wide, and the pumping speed can be maintained from atmospheric pressure to 1Torr pressure | The pumping range is wide, and the curve fluctuates greatly from the atmospheric pressure. The pumping speed of the liquid ring vacuum pump decreases significantly when it is below 50Torr, and it is easy to produce gas corrosion when it works for a long time under low pressure |

| Common cooling water | Vacuum pump jacket needs a small amount of cooling water to cool the compression heat, and the cooling water can be recycled cleanly:

Screw pump if the use of water cooling, cooling water is only 28L/Min |

The working medium of liquid ring vacuum pump is water or other liquid |

| Power | Under the same suction pressure, power consumption is lower than other types of vacuum pumps: power consumption is relatively constant:

The 1500 screw vacuum pump is equipped with 37KW motor and the shaft power is 22KW |

The power consumption varies with the temperature, flow rate, type of process gas and vacuum degree of the coolant, and the power consumption of the large oil and gas recovery liquid ring pump shaft power 75KW |

| Daily maintenance

maintenance |

Simple operation, easy maintenance, less wearing parts, low maintenance cost; Compact structure, small footprint, small water consumption | The operation is more complicated and the maintenance cost is higher, so it is necessary to replenish or replace the working liquid and clean the working liquid pipeline regularly |

| The price | higher

One-time investment, cost-effective |

The lower |

| Application | Solvent recovery, vacuum drying, chemical medicine, oil and gas recovery, aerospace, etc | Petroleum, chemical, machinery, mining, light industry medicine and food |

| Oil and gas recovery | Generally, there is no cooling water resources in oil and gas recovery plant, and the screw vacuum pump can use gasoline as jacket cooling medium, and the use of gasoline injection, professional technology to greatly reduce the pump chamber and exhaust temperature | Liquid ring vacuum pump needs to use additional working liquid medium, and should be equipped with vapor-liquid separation tank, pipeline pump, heat exchanger and other accessories |

Screw vacuum pump and liquid ring vacuum pump comparison between

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)