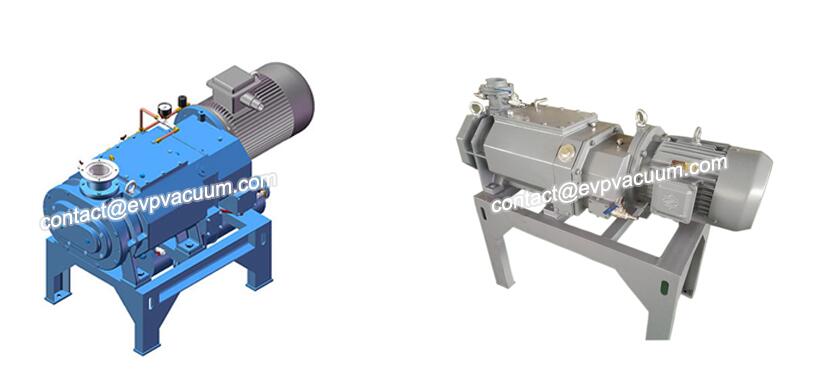

Screw vacuum pump industrial manufacturers

The screw vacuum pump industry manufacturer, screw vacuum pump may be many enterprises are familiar with and unfamiliar, familiarity means that this equipment has been widely affected in domestic enterprises for a long time, and has a certain understanding of its characteristics, advantages, performance and other aspects, for the help of enterprises after application. Help is also more thorough research, as equipment in various industries. But it is unfamiliar, because its utilization rate can not cover the domestic market, the price of some equipment also needs to be imported, and domestic production capacity restricts the development of equipment, so in-depth understanding of the application is unfamiliar.

In view of these two situations, many production enterprises, EVP oil-free screw vacuum pump, have slowly shifted production investment to screw vacuum pump in recent years. Although this is a good development direction, the use of dry pump will eventually be recognized by the domestic market, but for the current production capacity, there are also very few enterprises in China. Industry can achieve, Shandong screw vacuum pump manufacturers, and for such sophisticated equipment, high processing technology can truly reflect the advantages of the equipment.

In the future market, the application of screw vacuum pump will certainly become the focus of the domestic market, which is very conducive to the development of enterprises, and will also drive the whole vacuum pump market into another space to improve and expand its influence.

Screw Vacuum Pump of Industrial Application

(1) Screw vacuum pump in solvent recovery in pharmaceutical industry of application

The raw materials used in the solvent crystallization process are usually filtered, washed and vacuum dried after crystallization. The moisture content in the material is usually 20%~200%. The solvent in the wet material is usually flammable, explosive, toxic and harmful. They are removed by the vacuum unit during the drying process.

Roots-liquid ring vacuum pump unit is widely used in traditional wet vacuum system. Sealing fluid of liquid ring pump dissolves or absorbs part of organic solvent in operation, and separates waste gas and high concentration organic waste liquid in vapor-liquid separator. These two parts need to be treated, which not only can not fully recover this part of solvent, but also can make enterprise transport. With the increase of the cost, the health, safety and environmental protection will be challenged. The application of dry vacuum condensation system can condensate organic solvents in the exhaust side of the drying process, achieve solvent recovery, and zero discharge of waste water. Because there is no other process medium in the cavity of screw pump, the inner surface is protected by coating. Corrosion measures, both energy-saving and environmental protection, no waste liquid treatment problems, the solvent can also be completely recycled. So screw vacuum pump has become the best choice in this application field.

(2) Screw Vacuum Pump in Gasoline Steam Recovery in Petrochemical Industry of application

Dry screw vacuum pump is a key equipment in gasoline vapor recovery unit. The extracted gases are volatile gasoline vapors, mainly composed of gasoline vapors such as C4, C5 and C6.

Usually the operating temperature of the pump is required to be controlled below 80 C. However, the operation of the pump can not be reduced to such a low temperature only by cooling the jacket of the pump body. In addition, cooling water can not be provided in most fields. The cooling liquid that can be provided is gasoline. In order to reduce the operating temperature of the pump, besides injecting gasoline into the jacket of the pump body, The most effective method is to inject appropriate amount of gasoline into the pump chamber (at the highest temperature), so as to evaporate and absorb heat to reduce the temperature in the pump chamber.

In the process of oil vapor recovery of screw vacuum pump, condensed gasoline will accumulate at the exhaust port of the pump, which will cause abnormal vibration and noise of the pump, so it must be discharged in time. For this reason, the following three improvement measures can be taken.

Measure 1: The exhaust pipe of the pump inclines downward, and the position of the exhaust pipe is lower than that of the exhaust port of the pump.

Measure 2: Install a circulating pump at the exhaust port of the pump or the lowest position of the muffler to eliminate the accumulation of fluid.

Measure 3: Install a one-way valve at the outlet of the pump to prevent the condensate from flowing back into the pump chamber due to the siphon phenomenon when the pump stops running.

(3)Screw vacuum pump in space simulation of application

Because the volume of the container pumped by the space simulator varies from several thousand cubic meters to tens of thousands of cubic meters, the vacuum degree varies from tens of thousands of Pa to several Pa, and the gas pumped contains a large amount of water vapor or part of nitrogen oxides, the first problem encountered by this vacuum system is the pre-pumping vacuum problem, if the traditional slide valve pump is chosen as the one. The front stage pump has the following problems:

Firstly, the sliding valve pump operates for a long time under high inlet pressure. Because of the airflow carrying effect, its fuel injection phenomenon is very serious. First, it wastes a lot of expensive oil, and second, it pollutes the environment.

Because the pumped gas contains a large amount of water vapor or nitrogen oxides, once these gases enter the pump, the vacuum pump oil will quickly emulsify and deteriorate, and the sealing of the oil will be damaged, resulting in the decline of vacuum performance, or even the destruction of the pump.

The number of pumps needed to be equipped is large, and the vibration and noise of the sliding valve pump are also large.

Screw vacuum pump has become the preferred product of large-scale space simulation vacuum system because of its advantages of clean, oil-free, high pumping speed, low vibration and low noise. In addition, in order to improve the pumping speed and limit vacuum of the vacuum unit and reduce the size of the screw pump accordingly, a two-stage unit consisting of a Roots pump and a screw vacuum pump in series or a three-stage unit consisting of two Roots pumps and a screw vacuum pump in series are generally adopted. In order to prevent particulate impurities from entering the pump, the inlet filters are equipped at the entrance of the vacuum unit with a precision of 50 microns.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)