Screw vacuum pump of basic knowledge for new friends

The basic knowledge of screw vacuum pump is given to new friends just entering the industry

Screw vacuum pump is a new member of positive displacement vacuum pump. It appeared in the 1990s and developed later. However, as an ideal dry pump, screw vacuum pump has been developed rapidly after it came into being. Now let’s go and learn about its basic knowledge with Xiaobian!

1、 Screw vacuum pump of characteristics

Screw vacuum pump is an ideal dry vacuum pump in displacement vacuum pump, which is derived from screw compressor and screw liquid pump. It can provide a clean and oil-free vacuum environment, and has strong adaptability to corrosive gases, condensable vapors and dust containing particulate gases. Therefore, screw vacuum pumps are favored in some industries with strict requirements for clean vacuum environment and complex gas components, such as electronic semiconductor, pharmaceutical, petrochemical, etc., and gradually become the replacement products of traditional oil sealed mechanical pumps and liquid ring pumps.

Through the opposite movement of a pair of asymmetric screw rotors, the screw vacuum pump periodically changes the volume between the teeth to transport gas and achieve the purpose of pumping. It has the following characteristics:

1. Clean, oil-free, multiphase mixed transportation, wide adaptability. There is a strict clearance between the rotors of screw vacuum pump, and there is no oil in the pump cavity. It can extract corrosive gas, toxic gas, dust and condensable steam and other complex gases.

2. It has the advantages of simple structure, good dynamic balance and high reliability. Screw vacuum pump has few parts, no vulnerable parts and unbalanced inertia force in the core parts, so it has reliable operation and long service life.

3. Because of its simple structure and few parts, it is easy to operate, repair and maintain.

4. Forced gas transportation can ensure a large pumping speed in a wide range of pressure, and the displacement is almost not affected by the exhaust pressure.

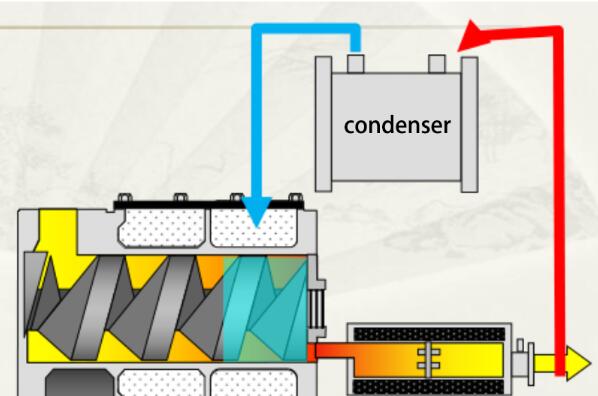

2、Screw vacuum pump of structure

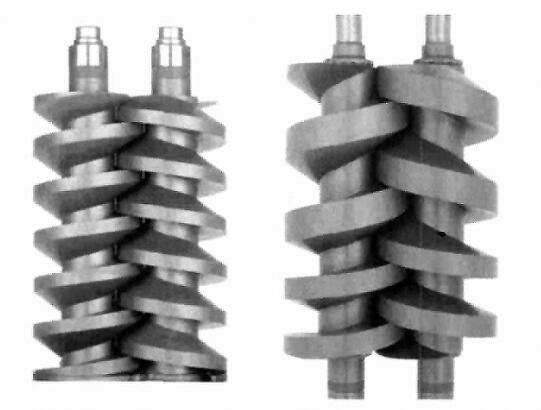

Screw vacuum pump is generally twin-screw structure. Screw type vacuum pump is a kind of pumping equipment which is driven by a pair of asymmetric screw rotors in the pump cavity in a synchronous and high-speed reverse operation, and periodically changing the volume between teeth.

Its main structure includes screw rotor, bearing, pump body, seal, etc. After fine dynamic balance correction, the screw rotor is supported by bearings and installed in the pump cavity. The screw and screw maintain a strict clearance. When the pump works, there is no friction between each other, the operation is stable, the noise is low, and there is no need for lubricating oil in the cavity. Therefore, the screw vacuum pump can remove large amounts of water vapor and a small amount of dust. It has the advantages of high vacuum limit, low power consumption, energy saving and maintenance free.

Screw vacuum pump of main structure

Screw vacuum pump is simple in structure. In form, screw vacuum pump has horizontal and vertical points; According to the screw rotor type line can be divided into single-head screw vacuum pump and multi-screw vacuum pump; According to the difference of rotor pitch, single-head screw vacuum pump can be divided into equal pitch screw vacuum pump and variable pitch screw vacuum pump, and variable pitch can be subdivided into one-stage type, two-stage type, three-stage type, etc.

Long lines within a lead which can complete suction, compression, exhaust process, less lead, which can effectively reduce the volume and weight of the pump, apply to the field of large pumping speed, but its complex type line, need special props and special machine tools, processing is expensive, and because of leakage triangle factors, vacuum degree is not high, so does not see more in the market.

Single – head line is suitable for small – and medium-sized screw vacuum pump, the market is more than single – head screw vacuum pump. Among them, there is no compression in the cavity of uniform pitch screw vacuum pump, which can easily discharge solid particles and condensable gases, but its exhaust temperature and energy consumption are high. Variable pitch screw vacuum pump cavity has compression, low exhaust temperature, low energy consumption, but dust particles and condensable gas tolerance is not as good as equal pitch.

Although due to cost of the type line technology and processing screw vacuum pump to purchase more expensive, but in the long run, the characteristics of its wide adaptability, high efficiency and energy saving environmental protection and low failure rate, maintenance can bring in running cycle higher comprehensive benefit and the social environment benefit, using the more extensive is the trend of the future.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)