South Africa vacuum pump supplier

Vacuum pump started, after more than 10 years of tortuous development. EVP’s own brand vacuum pump came out and entered the manufacturing field of vacuum equipment. At present, EVP vacuum pump manufacturer has grown into one of the leading manufacturers of water ring vacuum pump in China market. After years of investment and accumulation, the company has the core technology of products, and has the ability to develop new products independently. The comprehensive performance of products has the strength to compete with similar products of European and American brands.

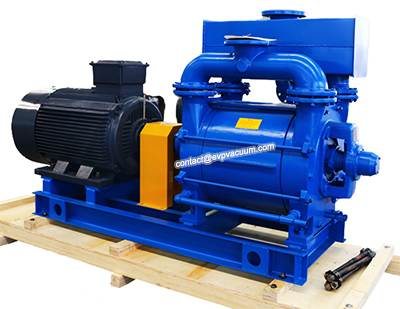

Vacuum equipment is an important part of plastic machine. We provide customized solutions according to the use characteristics of users in various industries, and walk out a sustainable development path. Our main product is water ring vacuum pump, which has a high market share and has become a leading brand in China. At present, water ring vacuum pump is widely used in papermaking industry, vacuum distillation and gas vacuum industry. Compared with the traditional products that have been used in the industry, the advantages of water ring vacuum pump are compact structure, reliable durability, energy saving and environmental protection.

Next, the South African vacuum pump supplier will share some selection skills of water ring vacuum pump.

1、 The type of water ring vacuum pump is mainly determined by the air volume, vacuum degree or exhaust pressure required for operation. When the pump works, the following two aspects should be paid attention to:

1. As far as possible, it is required to operate in the high efficiency area, that is, in the area of critical vacuum degree or critical exhaust pressure.

2. Operation near the maximum vacuum or exhaust pressure shall be avoided. In this area, not only the efficiency is very low, but also the work is very unstable, easy to produce vibration and noise. For vacuum pumps with high vacuum degree, cavitation often occurs when they operate in this area. The obvious sign of this phenomenon is that there is noise and vibration in the pump. Cavitation will cause damage to pump body, impeller and other parts, so that the pump can not work.

According to the above principles, when the vacuum degree or gas pressure required by the pump is not high, it can be selected in the single-stage pump preferentially. If the vacuum degree or exhaust pressure is high, the single-stage pump is often unable to meet the requirements, or the pump is required to have a large amount of air under a high vacuum degree, that is, the performance curve is required to be relatively flat under a high vacuum degree, so the two-stage pump can be selected. If the vacuum degree is required to be more than – 710mmhg, water ring atmospheric pump or water ring roots vacuum unit can be selected as the vacuum pumping device.

If it is only used for vacuum pump, it is better to choose single acting pump. Because the structure of single acting pump is simple, easy to manufacture and maintain, and it has good cavitation resistance under high vacuum. If it is only used for compressor with larger air volume, it is suitable to select double acting pump. Because of the large air volume, small volume and light weight of the double acting pump, the radial force can be automatically balanced, the shaft is not easy to produce fatigue fracture, and the service life of the pump is long.

2、 Select the vacuum pump according to the air volume required by the system

After the type of vacuum pump is preliminarily selected, the model of vacuum pump shall be selected according to the air volume required by the system. For the selection of pumping speed and calculation of pumping time of vacuum pump, please refer to the vacuum calculation formula.

At present, EVP vacuum pump product sales network all over the world, and in Europe, America, Australia, South Africa, the Middle East region set up dealers, product exports more than 50 countries.