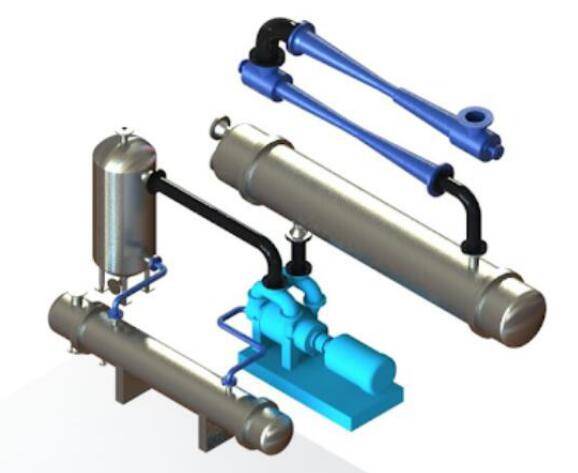

Steam ejector in vacuum crystallization system

Product description: Steam ejector is the main equipment of the vacuum crystallization system. It is widely used in titanium dioxide, mirabilite, sodium chloride, potassium chloride, chromium salt, boric acid, amino acid, lysine, monosodium glutamate, xylitol, etc. The product is in the crystallization process.

Steam jet pump series in vacuum crystallization system:

| Equipment | Output (10,000 tons/year) | The initial temperature and final temperature of acid ℃ | Working steam pressure KPaA | Cooling water temperature ℃ | Working steam consumption Kg/h | Cooling water consumption

t/h |

Power

Kw |

| Diacid crystallization system | 6.0 | 45/20 | 0.55 | 15/30 | 1410 | 380/60 | 22 |

| Titanium dioxide crystallization system | 1.5 | 55/15 | 0.5 | 32 | 1580 | 200 | 37 |

| Titanium dioxide crystallization system | 2.0 | 55/15 | 0.8 | 32 | 2100 | 210 | 75 |

Vacuum freezing crystal ejector

Vacuum crystallization of titanium dioxide

A large amount of ferrous sulfate is contained in the titanium solution obtained from ilmenite through acid hydrolysis and then leaching with water. The purpose of vacuum crystallization is to freeze the titanium solution until the ferrous sulfate reaches saturation and crystals are precipitated. In the vacuum and decompression state, the boiling point of the titanium solution drops to form a partial boiling, which causes the solvent to evaporate. Due to the latent heat of vaporization, a large amount of heat needs to be absorbed to quickly cool the solution and crystallize green alum crystals.

Features:

- High freezing efficiency

- Simple accessory equipment

- Low equipment investment cost

- Low production cost

- Equipment area is small

- High concentration of titanium solution after crystallization can reduce concentration workload

- High temperature at the end of crystallization

Installation instructions

The installation quality of the steam jet vacuum pump system has a great influence on its safe operation and working ability. Therefore, you must understand the installation procedures before installation. The following points are for reference when installing.

1.Preparations before installation:

①Before construction, the user must be familiar with the process flow chart and equipment installation general drawing; understand the assembly dimensions, assembly requirements, technical conditions and interconnected parts.

②Check the components to be installed and inspect each component. For unqualified products, the supplier should be notified to send someone to repair it.

③ Thorough removal of the inside of the installed parts, especially the debris in the steam pipe and cooling water pipe, is one of the main factors that cause the vacuum pump to work abnormally;

④ Strictly check the rust on the inner surface of the steam pipeline, and thoroughly remove the rust before installation. The use of severely rusted pipelines is prohibited.

⑤Check whether the position and size of the anchor bolts of the machine base where the equipment is installed are correct, and whether the height of the machine base meets the design requirements.

2.Installation:

①For the installation dimensions of each equipment, please refer to the overall equipment installation drawing

②When installing, start with the positioning and installation of each condenser, first hoist the first main condenser on the base, correct the installation position of the first main condenser, and fix the first main condenser completely after passing the test; mixed condensing The device must be installed vertically (allow vertical error less than 2°).

③The installation requirements of other condensers are the same as above.

④ Then connect all levels of ejectors between the system and the condenser. The connection type and arrangement of each ejector have been shown in the process flow chart and equipment installation diagram. The direction of the jet pump cannot be changed without prior consent.

⑤The installation height of the condenser of the steam jet straight air pump is 12 meters from the liquid level of the liquid sealed water tank at the condenser water outlet. The atmospheric leg should extend below the liquid surface, and the depth should be equal to its pipe diameter and not less than 200mm.

⑥The heavier and larger injectors of the first and second injectors should be supported and fixed.

⑦When installing steam pipes and cooling water pipes, no debris such as welding slag should remain in the pipes to prevent nozzle blockage.

⑧The steam pipeline should have heat preservation measures and be inclined to the steam sub-cylinder with a slope of 1%.

⑨When the steam jet vacuum pump is a single-stage pump or a multistage pump without an intermediate condenser, the installation height of the equipment is not limited. The installation height of the silencing condenser (direct cooling or indirect cooling) that exhausts the atmosphere is also not limited.

⑩After installation, the entire vacuum system is required to have good airtightness. All the connections of the vacuum chamber, vacuum pipes, drain pipes, and steam ejectors at all levels should be strictly sealed and tested for sealing.

3.Installation notes:

①Install the vacuum condenser drain pipe according to the condenser drain pipe size. When the following water pipes need to be bent and installed, the angle between the inclined pipe and the vertical pipe should not be greater than 45°, and the bottom of the drain pipe should be equipped with a flange for vacuum The equipment is used for sealing when performing air tightness test and leak detection.

②The pipes connected to the vacuum equipment should be equipped strictly according to the diameter required by the equipment installation general drawing, and the pipe diameter should not be changed at will.

③The gasket on the sealing surface of each connecting flange should be flat without creases, and the inner diameter of the gasket should not be less than the inner diameter of the pipe mouth.

④Install the water supply pipeline according to the design requirements. After the installation is completed, before connecting with the condenser interface, the water supply pipeline is purged, and then the water supply system is subjected to a hydraulic test. The test pressure is 0.4MPa (G), and the pressure is maintained for 30 minutes without leakage. , After the pressure test is qualified, remove the blind plate, and connect the water supply pipe to the condenser.

⑤ Install the steam supply pipeline according to the design requirements. After the installation is completed, the steam supply pipeline shall be purged before connecting to the interfaces of the jet pumps at all levels, and then the gas supply system shall be tested for air tightness. The test pressure is 1.0MPa(G). Press for 30 minutes without leakage. During the pressure test, the pressure should be gradually increased. After the pressure test is qualified, remove the blind plate and connect the steam supply pipe to the ejector.

⑥ After the installation is completed, all interfaces of the vacuum equipment are sealed with blind plates, and the vacuum equipment is leak-tight and pressure tested. The compressed air of 0.2MPa (G) is passed through and the pressure is maintained for 24 hours. The average pressure per hour is required. The drop is not more than 2%. The air pressure test should be carried out under the supervision of the safety department. The air tightness test of the vacuum equipment includes vacuum pumps at all levels, condensers, pump indirect pipes, and condenser drain pipes.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)