Two-stage rotary vane vacuum pump

In the last article, the structure and working principle of the single-stage rotary vane vacuum pump were described. It can be seen from the article that the ultimate pressure of the single-stage rotary vane vacuum pump can only reach 1.3pa (some can reach 0.1pa). Why can’t the ultimate pressure be lower? So this paper will be about the next two single-stage pump connected together in series, forming a two-stage rotary vane vacuum pump structure and working principle.

2XZ double stage rotary vane vacuum working principle

The two-stage rotary vane vacuum pump of type 2X is of two-stage structure. The working performance of the vacuum pump is composed of high-pressure stage and low-pressure stage. The suction inlet of the vacuum pump is connected with the vacuum container or vacuum equipment. When the equipment is vacuumed, the high-pressure stage exhaust valve plate will be closed, and the gas inhaled in the high-pressure stage will be transferred to the second stage, which will be inhaled and discharged, so that the vacuum equipment can obtain a certain amount of vacuum. The technical parameters of the two-stage rotary vane vacuum pump are 6 10-2pa. According to the user situation, can be equipped with vacuum booster pump, the pump as the front pump, by the booster pump pumping force to strengthen, front pump edge pumping, can make your equipment get very important vacuum.

2XZ two-stage rotary vane vacuum pump overview:

Model 2XZ rotary vane vacuum pump is a two-stage high-speed direct connection rotary vane vacuum pump (hereinafter referred to as the pump). It has a rotor mounted eccentrically in the pump chamber and a rotor blade in the rotor groove. When the rotor drives the rotation, the rotor piece is close to the wall of the cavity, separating the inlet and exhaust ports, and making the volume of the air intake cavity periodically expand and inhale, and the volume of the exhaust cavity periodically shrink and compress the gas, push the exhaust valve to exhaust, so as to obtain a vacuum. FIG. 1 is a schematic diagram of the working principle of single-stage pump. The double stage is a series of two single stages.

The 2XZ rotary vane vacuum pump is equipped with air ballast valve, which can prolong the service time of pump oil and prevent the mixing of pump oil and water.

The 2XZ rotary vane vacuum pump has the advantages of small volume, light weight, low noise and easy starting. In addition, there are measures to prevent oil return (2xz-8 without oil) and measures to prevent oil leakage and pollution of the site.

2XZ two-stage rotary vane vacuum pump

1, the pump is the basic equipment to obtain vacuum, it can be used alone, can also be used as all kinds of high vacuum system of the pre-pump and pre-pump.

2. The air inlet of the pump shall be continuously open for atmospheric operation and shall not exceed three minutes.

3, the pump is not suitable for the removal of corrosive to the metal month, chemical reaction to the pump oil, containing dust particles of gas, to the body containing oxygen is too high, there are explosive gas.

4, the pump shall not be used as a compression pump or delivery pump.

5, pump working conditions: temperature 5 ℃ to 40 ℃, relative humidity is not greater than 90%, the inlet pressure under the condition of less than 1333 pa allows continuous operation for a long time.

6. When connecting the power supply, wire according to the motor label, and note that the rotation direction of the motor is consistent with the direction of the arrow on the support.

7. The diameter of the pipeline that is continuously pumped into the container should not be less than the diameter of the air inlet of the pump, and the pipeline should be short and have few elbows. Meanwhile, pay attention to the leakage of the pipeline.

8. Check the oil level before starting each time. When stopping the pump, it is advisable to fill oil to the 4/5 height of the diameter of the oil gauge glass.

9. Pump oil: sy1634-701 vacuum pump oil is clean.

10, the pump can be in the air or any vacuum next start. If the xz-1 single-stage pump is difficult to start, the plug cap of the intake pipe can be removed to start and then put into operation.

Product display

Technical parameters

| Models | 2XZ -2C | 2XZ-4C | 2XZ-6C | 2XZ-8C | 2XZ-15C | 2XZ-25C | ||

| Pump speed | 50HZ (L/s) | 2 | 4 | 6 | 8 | 15 | 25 | |

| 60HZ (L/s) | 2.4 | 4.8 | 7.2 | 9.6 | 18 | 30 | ||

| 50HZ (m3/h) | 7.2 | 14 | 22 | 29 | 54 | 90 | ||

| 60HZ (m3/h) | 8.6 | 17 | 25 | 35 | 65 | 108 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ² | 6×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | |

| Total pressure | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Rotary speed(r/min) | 50HZ | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| 60HZ | 1720 | 1720 | 1720 | 1720 | 1720 | 1720 | ||

| Motor power(Kw) | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 3.0 | ||

| Working voltage(v) | 220/380 | 220/380 | 380 | 380 | 380 | 380 | ||

| InletDiam(mm) | I.D. | KF-25 | KF-25 | KF-25 | KF-40 | KF-40 | KF-40 | |

| O.D. | ||||||||

| Dimensions(mm) | Length | 480 | 520 | 545 | 616 | 705 | 830 | |

| Width | 150 | 150 | 172 | 255 | 255 | 275 | ||

| Height | 200 | 200 | 285 | 360 | 360 | 440 | ||

| Noise(dBA) | 65 | 65 | 68 | 70 | 70 | 72 | ||

| Oil capacity (L) | 0.8 | 1 | 1.5 | 3 | 3.5 | 4 | ||

| G.W./N.W. (kg) | 22/20 | 26/22 | 55/46 | 70/60 | 86/75 | 105/85 | ||

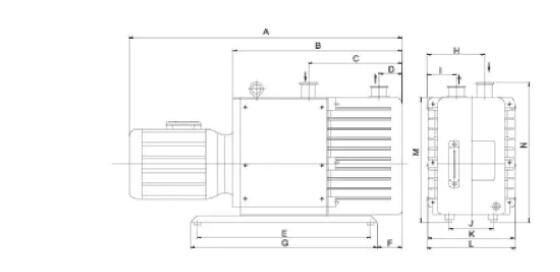

Installation dimensions

2XZ two-stage rotary vane vacuum pump order instructions:

1. Name of two-stage rotary vane vacuum pump;

2. Two-stage rotary vane vacuum pump model;

3. Two-stage rotary vane vacuum pump specifications;

4. Power of two-stage rotary vane vacuum pump;

5. Two-stage rotary vane vacuum pump voltage;

6. Operating temperature of two-stage rotary vane vacuum pump;

7. Two-stage rotary vane vacuum pump medium;