Two-stage vacuum pump

In the last article, the structure and working principle of single stage vacuum pump were described. Next, we would like to introduce our two-stage vacuum pump. Our company’s best-selling double-stage vacuum pump mainly has two types: double-stage water ring vacuum pump and double-stage rotary vane vacuum pump.

2SK series two-stage water ring vacuum pump

2SK series two-stage water ring vacuum pump is equivalent to two SK series water ring vacuum pumps in series.

Because SK series water ring vacuum pump can only reach the limit vacuum of -700mmhg, in order to achieve a higher vacuum and a higher pumping rate under high vacuum, in the 1980s, domestic development of 2SK series vacuum pump.

2SK series water ring vacuum pump overview

The 2SK series two-stage water ring vacuum pump and the 2sk-p1 series two-stage water ring vacuum pump and air jet pump units are used to extract air and other non-corrosive, water-insoluble, non-solids gases in order to obtain a higher vacuum in an airtight container.

It is widely used in food, weaving chemical industry, medicine and metallurgy industry and electronic fields of vacuum evaporation, vacuum concentration, vacuum moisture, vacuum impregnation, vacuum drying and vacuum smelting. It is characterized by high vacuum, high pumping speed in high vacuum area, compact structure, reliable operation and convenient maintenance.

2SK series are suitable for operating conditions with suction pressure lower than 0.08mpa. 2sk-p1 series are suitable for working conditions with suction pressure lower than -0.096mpa. When equipped with large air pump, the ultimate vacuum degree can reach -750mmhg.

The operating vacuum range is 0.03-0.08mpa.

Product display

Technical specifications

| Model | Suction capacity | Ultimate vacuum | Power | speed | Water supply | Inlet/outlet diam | Water inlet |

| m³/min | MPa(G) | KW | r/min | L/min | DN(mm) | (mm) | |

| 2SK1.5 | 1.35 | -0.097 | 4 | 1440 | 10-15 | 40 | G1/2” |

| 2SK-3 | 2.7 | -0.098 | 7.5/11 | 1440 | 15-20 | 40 | G1/2” |

| 2SK-6 | 5.4 | -0.098 | 15 | 1460 | 25-35 | 65 | G1/2” |

| 2SK-12 | 10.8 | -0.098 | 22/30 | 970 | 40-50 | 100 | G1/2” |

| 2SK-20 | 18 | -0.098 | 45 | 740 | 60-80 | 125 | G3/4” |

| 2SK-30 | 27 | -0.098 | 55/75 | 740 | 70-90 | 125 | G3/4” |

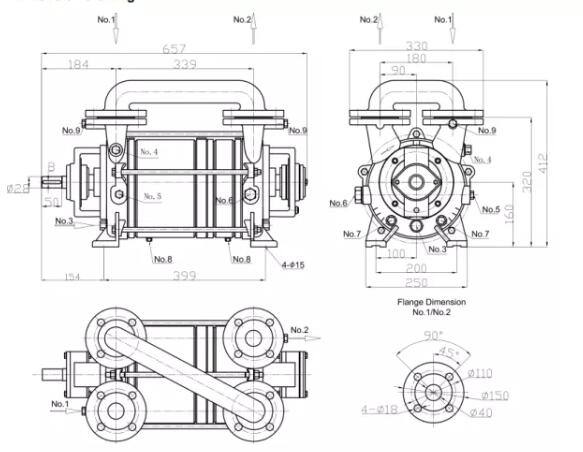

Installation dimensions

Model 2X-A double stage rotary vane vacuum pump

2x-a type two-stage rotary vane vacuum pump features:

1. Working requirements: when the inlet pressure is greater than 6500Pa, the continuous working time shall not exceed 3 minutes to avoid pump damage caused by oil injection.

2. Working requirements: the inlet pressure is less than 1330Pa, allowing continuous working for a long period.

3, environmental temperature, vacuum pump generally in 5 ℃ and 40 ℃ at room temperature and is not higher than 90% relative humidity environment in use.

4. Type of gas: clean and dry air without other mixtures at room temperature. No other dust or moisture is allowed.

5. Equipped with air ballast valve, which can remove a small amount of water vapor and extend the service time of oil pump (except for 2X-4A);

6, neon lamp manufacturing special vacuum pump, single crystal furnace, polycrystal furnace, laminator supporting vacuum operations.

7, can be used alone for the middle vacuum pump, can also cooperate with other high vacuum pump group for the pre-pump.

8, more than one pump tap operation, improve efficiency, can save energy.

Product display

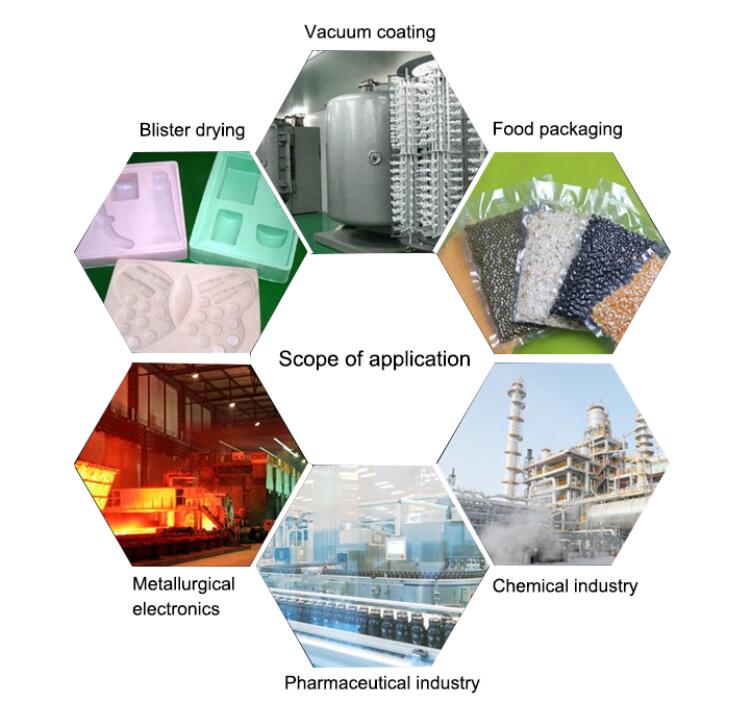

Scope of application

Technical specifications

| 2X-4A | 2X-8A | 2X-15A | 2X-30A | 2X-70A | 2X-100A | |||

| Pumping speed(L/s) | 4 | 8 | 15 | 30 | 70 | 100 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ²(5×10-4Torr) | ||||||

| Total pressure | 2.66(2×10-2 Torr) | |||||||

| Rotary speed(r/min) | 450 | 320 | 320 | 450 | 420 | 360 | ||

| Motor power(Kw) | 0.55 | 1.1 | 2.2 | 3 | 5.5 | 7.5 | ||

| Working voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Cooling Mode | Natural cooling | Water cooling | ||||||

| InletDiam(mm) | I.D. | 25 | 40 | 50 | 65 | 80 | 80 | |

| O.D. | 30 | 50 | 80 | 85 | 100 | 125 | ||

| Dimensions(mm) | Length | 540 | 790 | 790 | 810 | 910 | 1130 | |

| Width | 335 | 430 | 530 | 480 | 650 | 740 | ||

| Height | 380 | 540 | 540 | 560 | 700 | 690 | ||

| Oil capacity(L) | 1.0 | 2.0 | 2.8 | 3.0 | 4.2 | 5 | ||

| Recommend solenoid valve | DDC-JQ25 | DDC-JQ40 | DDC-JQ40 | DDC-JQ65 | DDC-JQ80 | |||

| Noise (dB A) | 65 | 70 | 70 | 70 | 75 | 90 | ||

| Weight(kg) | 60 | 158 | 202 | 230 | 480 | 560 | ||

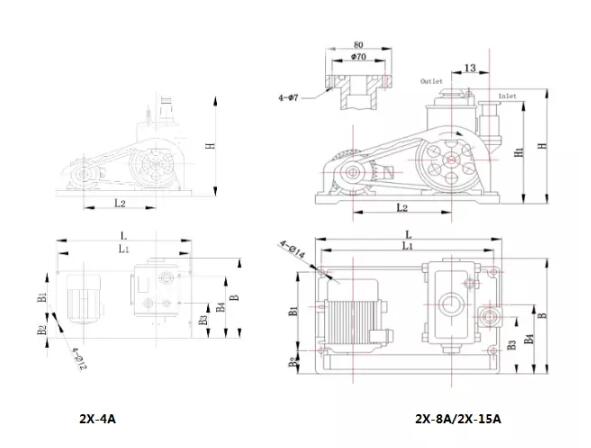

Installation dimensions

Related videos

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)