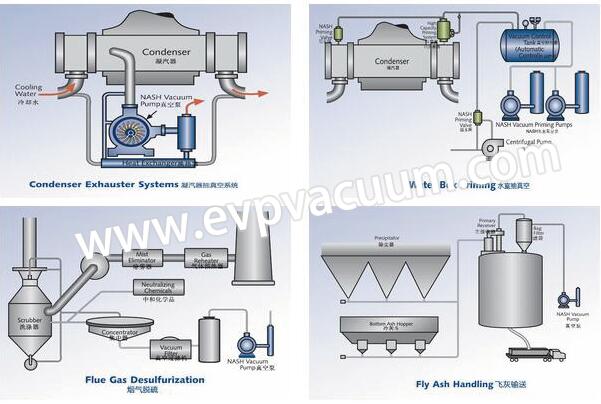

vaccum system for powe industry

Vacuum system solutions for power industry

Analysis of different solutions for condenser vacuum system:

Water ring unit: most commonly used, reliable operation, vacuum degree is greatly affected by cooling conditions, impeller is impacted by cavitation;

Water ring water ring pump with air ejector unit: the operating shaft power is higher than that of water ring pump, and the air extraction volume is greatly reduced compared with the water ring pump. The advantage is that the impeller is not easy to be damaged by cavitation;

Water ring pump with steam ejector: in the case of poor cooling conditions can be considered, high cost of steam;

Hydraulic jet unit: reliable operation, but high energy consumption and low efficiency;

The water ring pump is cooled by a refrigerator: the possibility of impeller cavitation is reduced, the pumping capacity is slightly increased, and the operation power is high;

Small pump instead of large pump: the actual leakage of condenser is smaller than the design value, the large pump is used to pump when starting the unit, and then the small pump is used to maintain the vacuum. The advantage is to save operation power consumption, but the disadvantage is that the vacuum degree cannot be increased when the leakage is small. When the leakage is slightly increased (not exceeding the design value), the normal vacuum degree of the condenser can not be maintained, and the power generation is reduced. The saved operation power consumption can not make up for the loss of less power generation, and the risk is too high;

Condenser vacuum degree lifting device: compared with the water ring pump, when the leakage is small, it can slightly improve the condenser vacuum degree (at least 0.1kpa), when the leakage is large, it can increase the vacuum degree up to 1kPa, bring huge benefits to increase the power generation, and save the operation power consumption.

Operation description

Turbine machine, with water ring vacuum pump group set up first, to achieve the water ring vacuum pumps can achieve limit value, start the vacuum lifting device and after reaching the set value, stop running water ring pump group and connected to the vacuum lifting device operation to upgrade the condenser vacuum to 0.1 KPa to 1 KPa, turbine running in the process of vacuum lifting device to the condenser vacuum has been maintained at a higher value.

Advantages:

Increasing the vacuum of condenser can improve the efficiency of generator set.

The energy saving effect is obvious and the operation cost is saved.

Reduce coal consumption, reduce carbon dioxide emissions, increase social benefits.

Unique patented technology.

Vacuum system for power industry is applicable to: