Vacuum pump for 50 gallon juice degasser

50 gallon fruit juice beverage vacuum degasser

Applications

Vacuum degasser, also known as vacuum degassing tank and vacuum degassing device, is used to degas the homogenized juice under vacuum to prevent oxidation of the juice and extend the juice storage period. In the juice processing, the deaeration of the juice is mainly used for deaeration and deoxidation by vacuum method, even if the juice is dispersed into a film or mist in a vacuum state to remove oxygen or other gases; the vacuum deaeration unit is suitable for various juice Beverages or other liquid foods are degassed and deoxygenated under vacuum; the degassed fruit and vegetable juice beverage can reduce or avoid the oxidation of juice components, and reduce the change of juice color and flavor. This equipment is equipped with a liquid level float valve, which can automatically control the liquid level of the material, and has a lighting lamp and a sight glass to observe the degassing of the material in the vacuum chamber. This equipment uses a frame to organically combine the vacuum pump, vacuum degassing tank, and conveying pump (screw pump), with simple structure, convenient operation, easy maintenance, small floor space, and beautiful appearance.

Technical Specifications

1.Production capacity: 1000 L/h~3000L/h

2.Working pressure: -0.054~-0.082MPa

3.Water ring vacuum pump: SK-1.5B Air extraction volume: 1.5m3/min Ultimate vacuum: 0.0047MPa Motor: 4kw / 2900rpm

4.Screw pump: Flow rate: 5.5T/h Maximum lift: 39m Maximum suction range: 8.5m Motor power: 3kw

5.Total power: 7Kw

Main structure and working principle

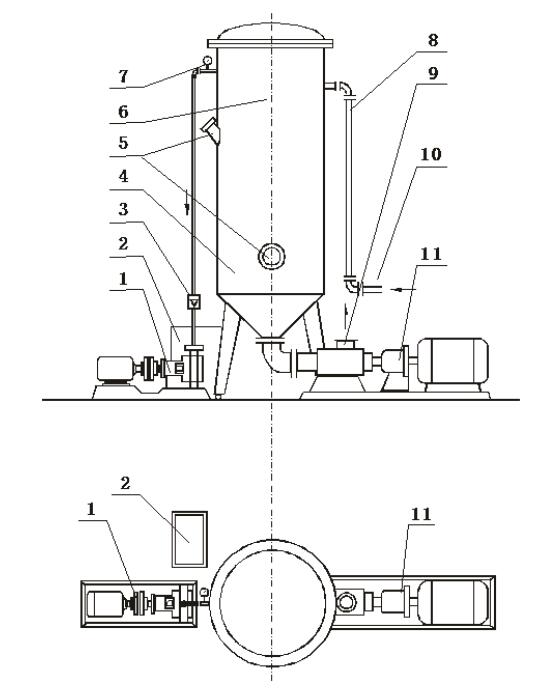

This equipment is composed of a stainless steel vacuum degassing tank, a screw pump, a water ring vacuum pump and a frame; the stainless steel vacuum degassing tank is equipped with a float valve near the bottom, which can automatically adjust the liquid level of the material. The material enters the upper part of the tank through the liquid level float valve and is ejected from the nozzle along the tangent line, spreads from the top into a film and falls along the tank wall. Due to the effect of vacuum, the gas dissolved in the juice can continuously escape. The top cover of the equipment is connected with a vacuum gauge, and is connected with a water ring vacuum pump with a pipe. The cone-shaped bottom outlet of the equipment is connected with a screw pump; the barrel of the equipment is attached with a detachable sight glass for observation and cleaning. At the bottom of the unit is a frame that organically combines these three machines. The frame is equipped with adjustable feet to adjust the height of the equipment. The top cover is sealed with a hinged structure and the cylinder body, making it easy to disassemble and clean.

Operation and maintenance

1.Before and after use, the inside of the equipment must be cleaned with hot water (90-95°C) and disinfected with steam.

2.Carry out regular maintenance. If the sealing ring is found to be aging or damaged, it should be replaced in time.

3.Keep all sealed parts in good condition during use and no air leakage.

4.Check the diaphragm pressure gauge frequently to keep it accurate.

1.Vacuum pump 2. Water pond 3. One-way valve 4. Tank body

Sight glass 6. Deaerator 7. Vacuum meter 8. Material inlet pipe

- Material outlet 10. Material inlet 11. Thick slurry pump

The following picture is a vacuum pump suitable for vacuum degassing of 50 gallons of juice: