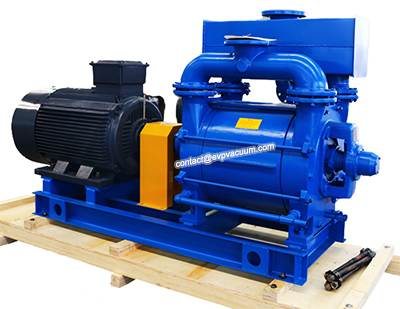

Vacuum pump for dry system

For many industries and fields, it is hard to imagine without vacuum drying technology. With the vacuum drying process, the liquid contained in the processing material is evaporated into steam and pumped out under the effect of pressure reduction.

Compared with heating drying, vacuum drying is faster, milder and more energy-saving. The process is especially suitable for drying chemicals, drugs, food and other applications where overheating can cause product damage or degradation.

Vacuum dryer is composed of refrigeration system, vacuum system, heating system, electrical instrument control system. The main components are drying box, condenser, refrigerating unit, vacuum pump, heating / cooling device, etc. The process of vacuum drying is to place the dried materials in a closed drying chamber, vacuum the dried materials with a vacuum system and heat them continuously, so that the water inside the materials diffuses to the surface through the pressure difference or concentration difference, and the water molecules obtain enough kinetic energy on the surface of the materials. After overcoming the mutual attraction between the molecules, they escape to the low-pressure space of the vacuum chamber, so as to be true The process of pumping.

The vacuum system used in vacuum drying equipment often causes the damage of vacuum pump. Because the purpose of vacuum drying is to remove water vapor. In addition, during the storage, transportation and manufacturing process of the dried materials or products as well as during the opening of the vacuum tank itself, it is inevitable to bring in a lot of dust and granular impurities. When the vacuum system is in the stage of high pressure pumping, these impurities may be brought into the cavity of the vacuum pump by turbulent air flow.

In order to avoid the damage of mechanical vacuum pump caused by the above reasons, in addition to cleaning the vacuum system as much as possible during the process, a filter screen can be installed at the air inlet of the vacuum pump to block the impurities and dirt that may enter into the pump cavity from the air inlet. The air inlet of the pump is provided with a dirt catching cavity to prevent the dirt from entering the air inlet in case of damage of the mesh of the air inlet of the pump or other reasons, and it can only fall into the dirt catching cavity instead of the vacuum pump cavity.

In order to prevent the dust and particulate matter in the pump oil from entering the pump cavity with the pump oil, a continuous pump oil filtration device should be set up during the operation of the pump for some technological processes. After the dust, impurities and polluted oil sink into the bottom of the main oil tank, it flows into the auxiliary oil tank through the return pipe for separation and sedimentation. The emulsified oil, water, dust and impurities sink into the bottom of the auxiliary oil tank and are discharged regularly by the drain valve. The relatively clean oil is filtered by the filter in the upper part of the auxiliary oil tank and then enters the oil distribution cavity through the oil inlet pipe before the supply end cover and pump cavity work.

The filter element in the filter blocks the mechanical pollutants when the oil passes and purifies the pump oil. Pressure gauge is often set on the filter to show whether the filter is blocked. When the pressure increases and the oil cannot flow normally, the filter is blocked, and the filter element should be replaced or cleaned.

The vacuum pump generally checks the oil quantity every week. The oil change interval depends on the working conditions. Generally due to poor oil lubrication, oil decomposition or too many pollutants make the pump limit pressure rise, it is necessary to change the oil.