Vacuum pump for vacuum drying oven?

Vacuum pump is one of the necessary accessories of vacuum drying box. When customers choose vacuum pump, they need to pay attention to the following matters:

1. The working pressure of the vacuum pump shall meet the requirements of the extreme vacuum and working pressure of the vacuum equipment. Such as: vacuum coating requirements 110-5mmhg vacuum, the selection of vacuum pump vacuum to at least 510-6mmhg. Usually the choice of vacuum pump vacuum than vacuum equipment vacuum half to an order of magnitude.

2, the correct choice of vacuum pump operating point. Each pump has a certain range of working pressure, such as: diffusion pump for 10-3~ 10-7mmhg, in such a wide range of pressure, the pump pumping speed with pressure, its stable working pressure range is 510-4~ 510-6mmhg. Therefore, the working point of the pump should be selected in this range, and can not let it work in 10-8mmhg for a long time. Another example is the titanium sublimation pump can work at 10-2mmhg, but its working pressure should be less than 110-5mmhg is good.

3, the vacuum pump in its working pressure, should be able to exhaust all the gas produced in the process of vacuum equipment.

4, the correct combination of vacuum pump. Because vacuum pump has optional take out air, consequently, sometimes choose a kind of pump to cannot satisfy take out air requirement, need a few kinds of pumps to combine, mutual complement just can satisfy take out air requirement. For example, the titanium sublimation pump has a high pumping speed for hydrogen, but cannot pump helium, while the three-pole sputtering ion pump (or the two-pole asymmetric cathode sputtering ion pump) has a certain pumping speed for argon. In addition, some vacuum pumps can not work under atmospheric pressure, the need for pre-vacuum; Some vacuum pump outlet pressure is lower than atmospheric pressure, the need for the former pump, so the pump needs to be used together.

5. Requirements for oil pollution of vacuum equipment. If the equipment strictly requires no oil, should choose a variety of pumps, such as: water ring pump, molecular sieve adsorption pump, sputtering ion pump, cryogenic pump. If the requirements are not strict, you can choose a pump, plus some anti-oil pollution measures, such as cold trap, baffle, oil trap, etc., can also meet the requirements of clean vacuum.

6, to understand the composition of the gas, the gas contains condensable steam, no particle dust, corrosion, etc. When selecting a vacuum pump, it is necessary to know the gas composition and select the corresponding pump for the pumped gas. If the gas contains steam, particles, and corrosive gases, it should be considered to install auxiliary equipment, such as condenser, dust remover, etc. on the inlet pipe line of the pump.

7, the vacuum pump exhaust oil vapor on the environment. If the environment does not allow pollution, you can choose oil-free vacuum pump, or the oil vapor exhaust to the outdoor.

8. Whether the vibration generated during the operation of the vacuum pump has any influence on the process and environment. If the process does not allow, should choose no vibration of the pump or take anti-vibration measures.

How to choose the vacuum drying chamber vacuum pump

There are two main vacuum pump:

1. According to the conditions of drying materials, if the water content of materials is more than 10%, water ring vacuum pump should be selected. In this way, the condenser and buffer tank can be excluded.

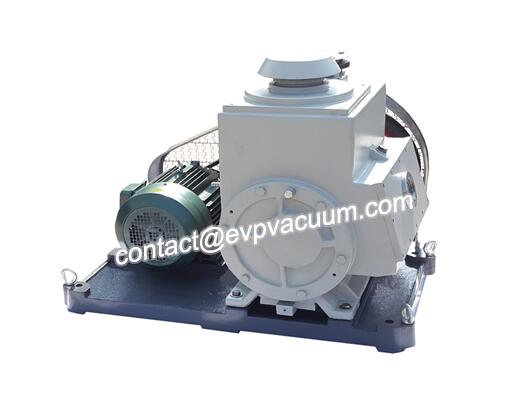

2. If the water content of the material is small, the rotary vane vacuum pump can be used. In this way, the condenser and buffer tank are not listed, which can improve the vacuum degree, generally at -0.097mpa.

3. For high vacuum degree and large water content of materials, rotary vane vacuum pump can be used, in addition to the tube condenser and buffer tank.

4, rotary vane vacuum pump generally USES vacuum pump oil as the vacuum medium, the advantages of high vacuum, generally can reach -0.097mpa, is also very convenient in use. But it also has some disadvantages, one is that the vacuum pump is more expensive, and the vacuum pump oil is often pumped into the gas containing water or pollutants, affecting the quality of the oil, the use of deterioration of the vacuum pump oil is easy to cause damage to the vacuum pump, need to replace the vacuum pump oil.

6, water ring vacuum pump generally USES water as the vacuum medium, the advantage is that water is more commonly used, easy to get, and the price of the vacuum pump is cheaper than the rotary vane pump, the disadvantage is that the vacuum degree is lower than the rotary vane vacuum pump, generally around 0.08mpa, when the vacuum reached more than 0.06mpa, the speed is slower than the rotary vane pump.

According to the above two kinds of vacuum pump performance for the vacuum drying box to choose the right vacuum pump can reduce the cost of waste in the process of use. Water ring vacuum pump can be used by users with low requirements for vacuum degree, and rotary vane vacuum pump can be used by users with high requirements for vacuum degree.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)