Vacuum pump group modification scheme – water ring vacuum pump

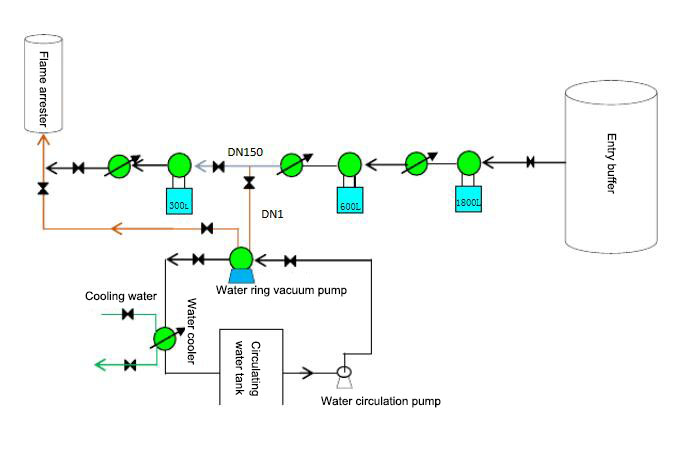

Now each group of vacuum pump is composed of 300 l, 600 l, 1800 l of roots vacuum pump, raw materials for the original design conditions of slurry oil, after the raw material is adjusted for wax crude oil, the process in the refining process of roof exhaust reduction high sulphur increased salt and solid impurities, cause the roots pump rotor, pump body parts such as corrosion in use process, was badly damaged and roots pump rotor clearance demanding, when using smaller impurities into the pump causing rotor clearance, the rotor are more serious wear and tear, pump operating load, noise big, over current, easy cause equipment accident, and affect production, the company’s property loss is very big, With central vacuum manufacturer communication, according to the nature of the device is now processing raw material advice each at the entrance of each group of tertiary roots vacuum pump increasing a stainless steel 316 l water ring pump valve roots vacuum pump in parallel with the original 300 l, switch to using a state, to reduce the number of roots vacuum pump repair, prolong service life, ensure the normal operation of equipment.

Water ring pump to introduction:

Vacuum pump group modification scheme – water ring vacuum pump

Water ring pump is composed of impeller, pump body, suction and exhaust disc, water in the pump body wall formed by the water ring, suction port, exhaust port, auxiliary exhaust valve. The process of compressed gas is isothermal, so it can be removed flammable, explosive gas, in addition to dust, water gas can be removed.

Water ring vacuum pump working principle:

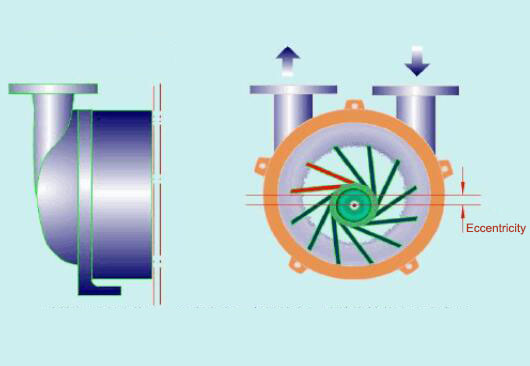

The pump body is equipped with appropriate amount of water as the working fluid. When the impeller rotates in the counterclockwise direction as shown in the figure, water is thrown around by the impeller. As a result of centrifugal force, water forms a closed ring of approximately equal thickness determined by the shape of the pump chamber.

If the lower part of the impeller is 0° as a starting point, the volume of the small cavity increases from small to large when the impeller is 180° before rotation, and it is communicated with the suction port on the end face. At this point, the gas is inhaled, and the small cavity is isolated from the suction port at the end of inhalation. When the impeller continues to rotate, the small cavity from large to small, so that the gas is compressed; When the small cavity and vent port connected, the gas is discharged out of the pump.

Compared with other types of mechanical vacuum pumps:

Water ring vacuum pump advantages:

Therefore, a small structure size can be used to obtain a large volume of air and a small floor area. Compressed gas is basically isothermal, that is, the process of compressed gas temperature change is very small. Because there is no metal friction surface in the pump chamber, there is no need to lubricate the pump, and the wear is very small. Sealing between rotating and fixing parts can be done by water seal directly. The suction is even, the work is stable and reliable, the operation is simple, the maintenance is convenient.

Water ring vacuum pump disadvantages:

Low efficiency, generally around 30%, better up to 50%. The vacuum is low, which is not only limited by the structure, but also by the saturated vapor pressure of the working fluid. Using water as working fluid, the limit pressure can only reach 2000~4000Pa. Oil as working fluid, up to 130Pa.

Schematic diagram of simple transformation process: