vacuum pump in vacuum forming and laminating process

Where are vacuum pumps used in forming, pressing and laminating applications?

In many industries and manufacturing technologies, vacuum forming, pressing and laminating are popular processes. These processes are used to connect a variety of materials together or to form a specific mold.

For forming, it is important to bring the material into the mold using a clearly defined vacuum. Thermoforming is a mature process, used for many products, is a process for forming plastic foil. For this process, the foil is heated to soften. Apply vacuum through the mold. This pulls the foil that has softened by the heating process into the mold. When the foil cools, it will maintain the shape of the mold.

Which vacuum pumps are particularly suitable for forming, pressing and laminating processes?

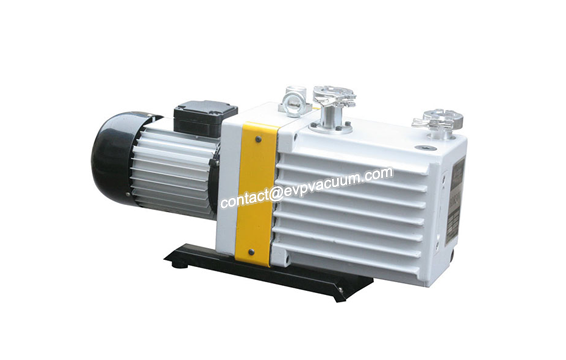

The application of rotary vane vacuum pump in the forming process has been tested by many years of practice, which represents the most advanced level at present.

Dry vacuum pump energy saving, mainly used for pressing process, such as furniture production. If the requirement of vacuum degree is high, the vortex dry vacuum pump can be the first choice.

Screw vacuum pump can discharge the leaked gas and steam without affecting the operation of vacuum pump, which is the preferred laminating process for solar cell module, flat screen and smartphone display screen.

In terms of forming, pressing and laminating applications, what are the applications of vacuum technology?

Vacuum forming, pressing and laminating are common processes in many industries and manufacturing technologies. Through these processes, various materials can be combined or customized.

As far as forming is concerned, it is very important to inject the material into the mold with a vacuum meeting the specific requirements. Among them, thermoforming is a conventional process in product production, which can make plastic film forming. In the thermoforming process, the plastic film is heated first to soften it. Then apply a vacuum to the mold. Under the action of vacuum, the plastic film that has been heated and softened is pulled into the mold. Once the plastic film cools, it forms the shape of the mold. This method can be used to make food and other commodity packaging, and also can be used to make preformed plastic mold shell of garden pool.

Vacuum pressing technology can be used in the wood industry. For example, when you want to paste multiple layers of wood together, but because of the geometry, you cannot use mechanical pressing, so you need to use vacuum pressing. In addition, vacuum technology can also paste or fix plywood or synthetic materials to the front of the kitchen and other similar boards.

Vacuum lamination is a process of combining multilayer materials, which is often used in semiconductor and electronic industries. This is how solar cells, flat screens and smart phone screens are made.

Application examples of vacuum technology in molding process:

Die exhaust – production of rotor blades for wind power plants

Thermoforming – production packaging

Application examples of vacuum technology in pressing process:

Press plate machine – glue the synthetic board to the furniture surface

Vacuum assisted resin transfer molding (vrtm)

Application examples of vacuum technology in lamination process:

Flat panel display lamination

Solar panel lamination

Thermoforming and Vacuum Forming create plastic parts by heating plastic material and pulling it over a mold under vacuum or pressure. rotary vane vacuum pumps produce deep vacuum and therefore are popular thermoforming pumps for thin gauge and heavy guage thermoforming. Our rotary vane vacuum pumps also serve the Twin Sheet Forming industry well.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)