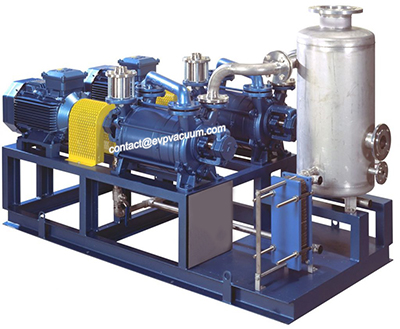

Vacuum pump system in deacidification process

Natural gas collected from oil and gas wells often contains H2S, CO2 and organic sulfur compounds. H2S and water can form sulfuric acid, CO2 and water can form carbonic acid, so it is called acid gas. We design different deacidification processes according to different gas conditions and requirements. The first choice of natural gas deacidification unit is vacuum unit. The application of vacuum pump system in natural gas deacidification unit is to use it for vacuum pump. At the same time, it has the characteristics of low energy consumption, compact structure, less land occupation, safety and stability.

Why dehydration and deacidification of natural gas?

Natural gas dehydration reason: natural gas is in contact with water, so it contains a certain amount of water vapor, which has the following hazards:

(1) In the presence of acid gases such as hydrogen sulfide and carbon dioxide, the condensation of water vapor can cause serious corrosion of pipelines.

(2) Natural gas and water can form hydrate to block the pipeline under certain conditions.

(3) When the light hydrocarbon in natural gas is recovered by low temperature separation, the water vapor condenses into water and then freezes, which can also cause pipeline blockage.

Reason for deacidification of natural gas: the main acid gases in natural gas are hydrogen sulfide and carbon dioxide. Hydrogen sulfide will increase the corrosion of pipelines and equipment, pollute the environment and cause catalyst poisoning in the post-processing process. Carbon dioxide will not only increase the corrosion of pipelines and equipment, but also reduce the calorific value of natural gas.

Application of vacuum pump system in natural gas deacidification unit.

The principle of natural gas deacidification is that the deacidification unit in the natural gas treatment plant can effectively remove H2S, CO2, cos, RSH and other acidic components in the natural gas, ensure production safety and prevent equipment pipeline corrosion. The shallow stripping process is applicable to the production of commercial natural gas (H2S content ≤ 6mg / m3, CO2 content ≤ 2mol%, organic sulfur content ≤ 200mg / m3).

Its main advantages:

(1) Deacidification by amine method (MDEA): it is widely applicable to different natural gas compositions.

(2) Solid adsorption desulfurization: it is suitable for gas wells with low sulfur content, high treatment depth requirements and remote dispersion.

(3) Membrane separation deacidification: it is suitable for crude separation of natural gas with high acid gas concentration.

Application characteristics of vacuum pump system in natural gas deacidification unit:

The vacuum pump system has the characteristics of simple structure, reliable operation, long service life, convenient installation and maintenance, good sealing performance, and large pumping capacity. The composition of natural gas deacidification device includes acid gas absorption tower, which is respectively connected with mixer, scrubber, acid gas absorbent regeneration tower, the first flash tank and the second flash tank. The first flash pipeline is connected with the first flash tank The first flash pipeline is provided with a first flash valve; the upper part of the first flash tank is connected with the bottom of the acid gas absorbent regeneration tower through a compressor; the lower part of the second flash tank is provided with a second return pipeline, the second return pipeline is connected with the first return pump, the first return pump is respectively connected with the acid gas absorbent regeneration tower and the second return pump through the corresponding second return branch, and the second return pipeline is connected with the acid gas absorbent regeneration tower and the second return pump The flow pump is used to connect with the acid gas absorption tower. After being compressed by the compressor, the flash gas lean absorbent enters the middle and lower part of the acid gas absorbent regeneration tower again to provide heat for the acid gas absorbent regeneration tower, which saves energy consumption compared with the process that the equal amount of steam is all generated by the reboiler.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)