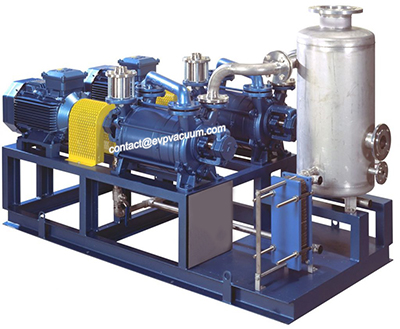

Vacuum system in vacuum degasser

Recently, many customers have asked us what kind of supporting equipment is needed for the vacuum degasser. In order to answer most people’s doubts, here, EVP vacuum pump manufacturer will explain to you. It is recommended to use the vacuum system in the vacuum degasser. As for the reason, let’s see the EVP vacuum pump manufacturer for your analysis. Vacuum degasser is a device which uses vacuum suction to remove the non condensable gas contained in the feed liquid. It is a necessary degassing equipment for the operation line of dairy products, juice and other materials.

The function of the vacuum degasser is to remove the air (oxygen) in the material liquid, inhibit the browning, pigment, vitamin, fragrance and other substances oxidation, and prevent the quality reduction; remove the suspended particles gas attached to the material liquid, inhibit the particles floating up, and maintain a good appearance; prevent the foaming of the tank and high temperature sterilization from affecting the sterilization; reduce the corrosion of the inner wall of the container, and play an anti-corrosion role Effect.

First of all, we must understand the characteristics of the special vacuum system of the vacuum degasser.

1. It can greatly shorten the exhaust time after the first water injection of heating or cooling system, which is very conducive to the first commissioning of the system.

2. Remove the gas in the system, prevent gas resistance, and ensure the stability and reliability of the system during normal operation.

3. Eliminate water pump cavitation and reduce system operation noise.

4. As the oxygen in water is removed, the aerobic corrosion of the system will be reduced and the service time of the equipment will be prolonged.

5. Because the gas in water is removed, there is no gas bubble on the surface of the heat exchanger, which improves the heating efficiency.

6. The working time and cycle of degasser can be adjusted as required.

7. The capacity of a single applicable system can be up to 150 m3, and multiple units can be used in parallel.

8. The equipment is easy to install, fully automatic operation, safe and reliable, easy to maintain.

Use steps of vacuum degasser:

When in use, as long as the matching vacuum pump is turned on, the air in the device is pumped out, and the material is sucked into the device from the feed inlet. When the material rises to a certain position, the control valve automatically controls the material. At this time, the feeding speed can be observed and controlled from the sight hole. When the vacuum degree in the device meets the technical requirements, the material can be pumped out from the outlet of the material, as long as the vacuum degree and the balance of the material in and out are maintained, Then production can continue. In order to prevent corrosion, the water supply system in the structure of power generation equipment can eliminate the non condensing natural gas, carbon dioxide, nitrogen, air mixed with water supply and maintain a certain suction head of water pump together with the open heat exchanger for water supply heating.

vacuum system in vacuum degasser application advantages:

1. The degassing effect is good. As a result of the driving gas input, a large number of bubble cores are formed in the riser, and the molten steel entering the vacuum chamber is sprayed into fine droplets, which greatly increases the degassing surface area of the molten steel, so it is conducive to degassing.

2. The temperature drop is small. Generally, the temperature drop of the treatment is only 30-50 ℃, and electric heating can be carried out in the degassing process, so only a little overheating is needed in the furnace.

3. The treatment range is large. The same equipment can deal with different capacity of molten steel, and can also be used in electric arc furnace and induction furnace.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)