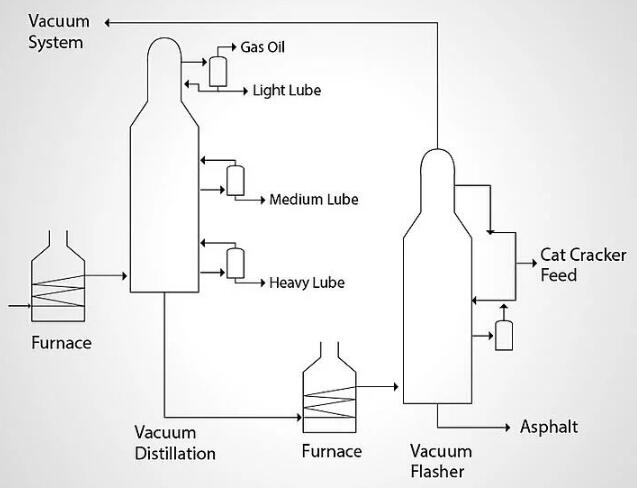

Vacuum system in vacuum tower system

The vacuum system of vacuum tower system, the treatment capacity of atmospheric and vacuum unit represents the scale and processing capacity of petroleum refining enterprises, and effective vacuum pump system can make atmospheric unit obtain large output of sidestream distillate. At present, in the atmospheric and vacuum distillation unit of crude oil, the special vacuum system at the top of vacuum tower generally adopts the vacuum pump system of steam jet extractor or mechanical vacuum pump system.

Generally, two-stage steam vacuum pump system is used in steam vacuum pump system, and three-stage vacuum pump system is often used in dry vacuum distillation. The residual pressure at the top of the vacuum tower of the two-stage steam vacuum pump system is usually 3-5kpa, which leads to low extraction rate of vacuum distillation and low operation flexibility of the vacuum tower. If the three-stage steam vacuum pump system is used, the vacuum degree of the vacuum tower can be increased, but the consumption of steam and cooling water will increase greatly, which will increase the energy consumption of the unit. In addition, the steam with pressure above 0.8MPa is generally used in the steam extractor. When the steam pressure fluctuates or the vacuum tower operation fluctuates, it is easy to cause vacuum fluctuation, which will affect the vacuum distillation operation, product quality and yield.

In addition, in the vacuum pump system of steam exhauster, the pressure of non condensable gas at the outlet of the last stage condenser is often close to the atmospheric pressure. Due to the low pressure, the non condensable gas can not be sent to the burner of the heating furnace for combustion, and the combustion of the burner will be extinguished from time to time, which will affect the smooth operation of the heating furnace.

Although the energy consumption of mechanical vacuum pump system is low, due to the domestic machinery manufacturing, anti-corrosion, maintenance and other reasons, the large-scale mechanical vacuum pump can not operate safely for a long period, so it is not suitable for use in large-scale vacuum distillation unit. It is only used in small atmospheric and vacuum distillation unit with annual crude oil processing capacity of less than 300000 tons. However, the equipment is seriously corroded and the maintenance cost is high.

The vacuum tower vacuum pump is improved to reduce the pressure fluctuation of vacuum tower and improve the operation pressure of vacuum tower. In addition, the final non condensable gas discharged from the vacuum pump system is properly pressurized to heat the furnace burner for stable combustion.

Through the operation of the vacuum system, it is found that compared with the traditional steam exhauster, although the initial investment cost is higher, because of its simple structure, easy maintenance and maintenance, multiple debugging can be selected according to the use, frequency conversion adjustment, low energy consumption and less sewage treatment cost. In fact, the application economy of vacuum system in vacuum tower system is better than that of steam vacuum extractor. And its structure is more in line with the vacuum tower system.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)