water ring vacuum pump installation instructions

The exhaust pipe of water ring vacuum pump or compressor is connected with the intake pipe of gas-water separator. When used as compressor, the exhaust pipe of gas-water separator is connected with the system using compressed gas. Generally, the pipeline shall not be too long and the turning shall not be too fast. When used as a water ring vacuum pump, the gas is discharged to the atmosphere from the exhaust port of the water gas separator. In order to improve the working environment, the gas can be discharged out of the working place through the pipeline.

The intake pipe of water ring vacuum pump or compressor shall be equipped with gate valve, so as to shut down the pump first when stopping, so as to prevent the water in the water ring vacuum pump or compressor from returning to the system under the pressure of the exhaust pipe. In order to facilitate the work, it is better to install a vacuum gauge between the air inlet and the valve, so as to check whether the working condition of the water ring vacuum pump is normal at any time. When it is used as a compressor, a gate valve shall be installed on the exhaust pipe of the gas water separator (preferably a one-way valve to ensure that in case of abnormal conditions, the gas will not return to the system, so that the working water will return to the system). A pressure gauge shall be installed between the exhaust pipe and the valve to check whether the compressed gas reaches the required pressure at any time.

Filter screen shall be installed before the air inlet of water ring vacuum pump or compressor to prevent particles from entering the pump.

water ring vacuum pump start and stop:

water ring vacuum pump startup:

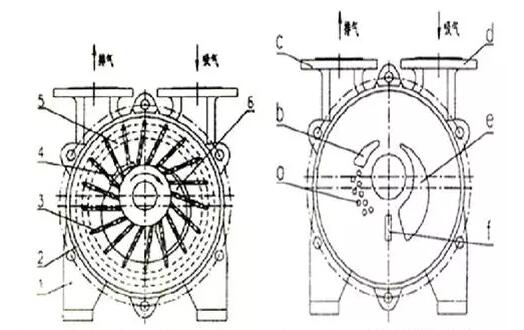

Before the long-term stop water ring vacuum pump is started, it must be turned by hand for several weeks to confirm that there is no jamming or other damage in the pump. The start-up is carried out in the following order (refer to the equipment description drawing).

1) Close the gate valve 4 on the air inlet pipe;

2) Start the motor (from the transmission direction, the motor rotates clockwise, the right side is the suction port, the left side is the exhaust port). The water ring vacuum pump is a mechanical seal, the mechanical seal should be filled with water before starting the motor;

3) Open the valve 6 on the water supply pipe or directly use tap water to supply water to the water ring vacuum pump to gradually increase the water supply until the water supply meets the specified requirements;

4) When the water ring vacuum pump reaches the limit vacuum or the maximum pressure, open the valve 2 on the intake pipe, and the pump starts to work normally;

5) Adjust the packing gland to make the water drip outwards;

6) The valve is used to adjust the water supply from the gas-water separator to the water ring vacuum pump, so as to operate under the required technical conditions, minimize the power consumption, reach the performance index and meet the working requirements;

7) Adjust the water quantity of the gas water separator supplied by the water supply pipe, so as to use the minimum water consumption and ensure the required technical specifications in the water ring vacuum pump;

8) When the water ring vacuum pump works under the limit pressure, the explosion sound may occur in the pump due to the physical effect, but the power consumption does not increase. The valve on the intake pipe can be opened to let it enter a small amount of gas, and the explosion sound disappears. If the explosion sound does not disappear and the power consumption increases, it indicates that the water ring vacuum pump has failed and should be stopped for maintenance.

water ring vacuum pump stop:

Parking shall be in the following order:

1) Close the valve on the intake pipe (for compression, close the valve on the exhaust pipe first, and then close the suction valve);

2) Close the gate valve on the water supply pipeline. After the water supply is stopped, the water ring vacuum pump should not be stopped immediately. Keep the pump running for 1-2 minutes to discharge part of the working fluid. The pump is a mechanical seal, and the cooling water of the mechanical seal cannot be closed;

3) Turn off the motor, and then turn off the mechanical seal cooling water;

4) If the shutdown time is more than one day, the water in the water ring vacuum pump and air-water separator must be drained to prevent rust.

water ring vacuum pump maintenance:

1. Check the operation and lubrication of the bearing of water ring vacuum pump regularly.

2. The normal working bearing is 15 ℃ – 20 ℃ higher than the surrounding temperature, and the maximum temperature is not allowed to exceed 55 ℃ – 60 ℃: the normal working water ring vacuum pump bearing shall be filled with oil 3-4 times a year. Clean the bearing at least once a year and replace the lubricating oil traction part.

3. If the packing is sealed, the packing shall be pressed regularly. If the packing cannot guarantee the required sealing performance due to wear, the new packing shall be replaced. The packing must not be pressed too tight. The normally pressed packing allows water to drip out to ensure the cooling of water ring vacuum pump and enhance the sealing performance.

If the mechanical seal is used and leakage occurs, check whether the dynamic and static rings of the mechanical seal are damaged or the sealing rings are aged. If the above situations occur, replace the new parts of the water ring vacuum pump.

water ring vacuum pump disassembly and assembly:

water ring vacuum pump disassembly:

The disassembly of the water ring vacuum pump is divided into partial disassembly inspection, complete disassembly, repair and replacement of parts. Before disassembly, the water in the pump cavity shall be discharged, and the air inlet and exhaust shall be removed. During disassembly, all pads shall be carefully removed. In case of damage, new pads of the same thickness shall be abstracted during assembly. The pump shall be disassembled from the rear end (one end without coupling) in the following order:

1. Loosen and remove the two connecting pipes;

2. Loosen and remove the rear bearing gland;

3. Loosen the round nut with hook plate hand and remove the packing gland;

4. Loosen the gland nut and remove the gland:

5. Loosen the connecting bolt of the pump body and the end cover and the accumulated bolt at the pump foot;

6. Add a support under the pump body, and then remove the lower end cover from the shaft;

7. Remove the pump body. Sk type water ring vacuum pump has been disassembled so far. At this time, the working part of the pump and all parts can be inspected and cleaned. Complete disassembly shall be carried out in the following order:;

8. Loosen the other pump foot bolt and remove the pump head from the base;

9. Take off the coupling of water ring vacuum pump

10. Remove the key of the coupling from the shaft

11. Remove the front bearing gland;

12. Loosen the back-up cap of the bearing and take down the bearing frame and bearing;

13. Loosen the compression nut of the packing gland and remove the packing gland;

14. Remove the shaft and blade from the end cover together;

15. Remove the shaft sleeve from the shaft;

16. Take the impeller from the shaft.

After the removal of the water ring vacuum pump, the fitting surface and thread shall be wiped and coated with oil carefully.

Water ring vacuum pump assembly:

1. Before assembly, clean the gasket left on the mating surface and wipe it carefully:

2. Remove the old oil in the bearing and bearing frame and replace with new oil:

3. The assembly sequence is opposite to the disassembly sequence.

During assembly, the most important thing is to adjust the clearance between the impeller end face and the disc on the end cover, which directly affects the performance of the water ring vacuum pump. The total clearance on both sides is specified in the table below, which is obtained by adding a pad between the pump body and the end cover. The clearance on both ends of the impeller should be uniform, and the water ring vacuum pump shaft sleeve or back cover can be tightened to move the impeller for adjustment.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)