Water ring vacuum pumps advantages

Multiple of water ring vacuum pumps simultaneous use of advantages

1. Water ring vacuum pump has simple structure, low processing and manufacturing requirements, no need for suction and exhaust valves, smooth operation and even air volume;

2. The compression of gas by water ring vacuum pump is close to isothermal compression, with little temperature change during compression. There is no metal contact surface of mutual friction in the vacuum pump, so it is not easy to occur combustion and explosion accidents;

3. The rotating part and the fixed part in the vacuum pump cavity are sealed by liquid, without lubrication, simple maintenance, easy operation, stable and reliable work;

4. According to the operation results, the drainage efficiency of the main drainage vacuum pump is significantly improved after the water ring vacuum pump is used. Meanwhile, the starting procedure is simplified to reduce the labor intensity when the vacuum pump is started.

5. After the water ring vacuum pump is used, the inlet bottom valve of the suction pipe is cancelled, and the suction water is unobimpeded to improve the drainage efficiency of the vacuum pump;

6. Since the direction of water injection in the water injection tube is from bottom to top, when the water level rises to the vacuum pump body, it can ensure that there is no air in the suction pipe and the vacuum pump body and prevent cavitation, which is conducive to the daily maintenance of the main drainage vacuum pump.

The way of using vacuum pump to start the big vacuum pump is beneficial to realize the automatic remote control of the main drainage system and creates the conditions for the digital mine construction. Water ring pumps were first used as self-priming pumps and then gradually used in petroleum, chemical, machinery, mining, light industry, medicine and food and many other industrial sectors

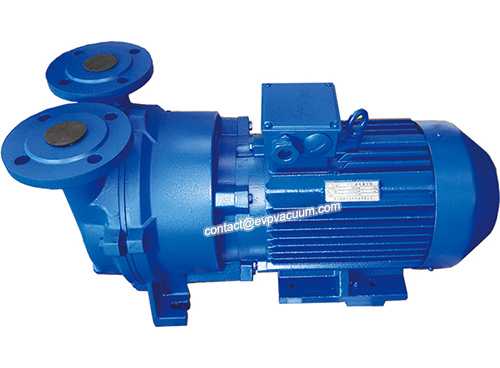

2BE series water ring vacuum pumps and compressors

The vacuum pump body is equipped with appropriate amount of water as the working fluid. When the impeller according to the direction indicated in the figure clockwise rotation, water is thrown to the impeller around, because of the effect of centrifugal force, water formed a determined by the shape of the vacuum pump chamber is approximately the same thickness of the closed ring. The inner surface of the upper part of the water ring is exactly tangent to the hub of the impeller, and the inner surface of the lower part of the water ring is just in contact with the tip of the blade (in fact, the blade has certain insertion depth in the water ring). At this time, a crescent-shaped space is formed between the impeller hub and the water ring, which is divided by the impeller into a number of small cavities with the same number of blades. If the upper part of the impeller is 0° as a starting point, the volume of the small cavity increases from small to large when the impeller is 180° before rotation, and it is communicated with the suction port on the end face. At this point, the gas is inhaled, and the small cavity is isolated from the suction port at the end of inhalation. When the impeller continues to rotate, the small cavity from large to small, so that the gas is compressed; When the small cavity and vent port connected, the gas is discharged out of the vacuum pump.

Simple structure, manufacturing precision requirements are not high, easy to process.

Compact structure, vacuum pump speed is higher, generally can be directly connected with the motor, without reducing the device. Therefore, a small structure size can be used to obtain a large volume of air and a small floor area. Compressed gas is basically isothermal, that is, the process of compressed gas temperature change is very small. Because there is no metal friction surface in the vacuum pump chamber, there is no need to lubricate the vacuum pump, and the wear is very small. Sealing between rotating and fixing parts can be done by water seal directly. The suction is even, the work is stable and reliable, the operation is simple, the maintenance is convenient.