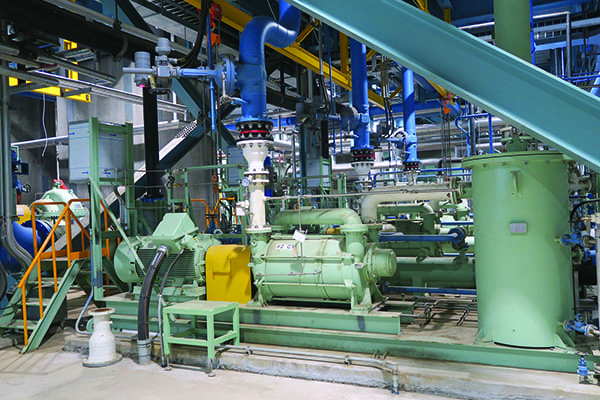

Water ring vacuum unit in petrochemical distillation process

The water ring vacuum unit is mainly used as the vacuum obtaining equipment in the process of petrochemical distillation. Each distillation tower with heat sensitive medium must adopt low pressure, atmospheric pressure and vacuum distillation. The exhaust gas produced by atmospheric pressure and vacuum distillation can not only meet the requirements of national and industrial safety, environmental protection and occupational health, but also the absorption tower and water ring vacuum pump can be arranged in the unit nearby, which has the characteristics of low equipment investment, low management cost and no increase of personnel. The operation results show that the absorption water ring vacuum pump pressurization torch combustion technology solves the problem of difficult treatment of exhaust gas in the separation of heat sensitive materials, which is worth popularizing and applying in similar devices.

Water ring vacuum unit is a kind of special equipment used to manufacture vacuum state. It has been widely used in many processes of petroleum, chemical industry, machinery, mine, light industry, papermaking, power, metallurgy, medicine, food and municipal and agricultural sectors (such as vacuum filtration, vacuum feed, vacuum degassing, vacuum evaporation, vacuum concentration and vacuum moisture return). Because the process of compressed gas in water ring vacuum pump is isothermal, the flammable and explosive gas and the gas containing dust and water can be removed. The application of water ring vacuum pump is increasing day by day.

In the process of petrochemical distillation, water ring vacuum unit is mainly used as the vacuum obtaining equipment of vacuum distillation. The equipment of water ring vacuum unit is composed of water ring vacuum pump, gas-liquid separator and heat exchanger. The water ring vacuum unit is installed near the condenser on the top of the vacuum distillation tower to extract the non condensable gas from the cooler. The gas enters the water ring vacuum unit through the front gas-liquid separation tank. The gas enters the rear gas-liquid separator after compression. After liquid separation, the non condensable gas at normal temperature and pressure enters the subsequent treatment system. Generally, a vacuum of – 0.092-0mpa can be produced by a single water ring unit. Water ring vacuum pump can also be used as the front pump of Roots vacuum pump, which can form a higher vacuum degree.

The water ring unit can pressurize the absorbed non condensable gas and send it to the flare system for combustion treatment, which can also meet the requirements of environmental protection.

Water ring vacuum unit in petrochemical distillation process

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)