What is helium mass spectrometer leak detector

Helium mass spectrometer leak detector is a term used in gas industry. It uses helium or hydrogen as leakage indicator gas and uses gas analyzer to detect helium for leak detection. Helium has low background noise, small molecular weight and viscosity coefficient, so it is easy to pass through the leakage hole and easy to spread; in addition, helium is an inert gas, which does not corrode the equipment, so it is commonly used as leakage gas. Spray the gas onto the tested container connected with gas analyzer (adjusted to the working state of reacting only with helium). If there is a leak in the container, the analyzer will react, so as to know the location of the leak and the size of the leak.

helium mass spectrometer leak detector product introduction :

Helium mass spectrometer leak detector specially used for power plant leak detection. Key components are imported, stable and reliable performance. It is not only highly sensitive, but also easy to operate. It can automatically switch the double filament, automatically adjust the zero, automatically calibrate and automatically switch the measuring range.

helium mass spectrometer leak detector main technical parameters :

1. Minimum leak detection rate: 5 × 10-12pa · m3 / S

2. Leakage rate display range: 1 × 10-3-1 × 10-12pa · m3 / S

3. Starting time: ≤ 5min

4. Response time: ≤ 1s

5. Maximum pressure of leak detection port: 1500pa

6. Power requirements: 220V, 50Hz, single phase, 10A

7. Working environment: 5-35 ℃

8. Relative humidity: ≤ 80%

9. Boundary dimension: 550 (W) × 400 (d) × 780 (H)

10. Weight: 64kg

helium mass spectrometer leak detector advantages:

1. Portable design

2. Beautiful and compact appearance

3. LCD touch screen design

4. Communication interface

5. Leak detection data can be output easily

helium mass spectrometer leak detector use environment:

Ambient temperature: 5 ~ 35 ℃

Relative humidity: < 80%

Power supply voltage: single phase AC 220V ± 10%, 50Hz maximum working current: 10A

helium mass spectrometer leak detector main configuration:

1. Special molecular pump for leak detector

2. Mechanical pump or dry pump

3. Customized special solenoid valve for leak detector

4. Built in standard leak

5. Amplifier

6. Special module for mass spectrometry

Helium mass spectrometer leak detection method:

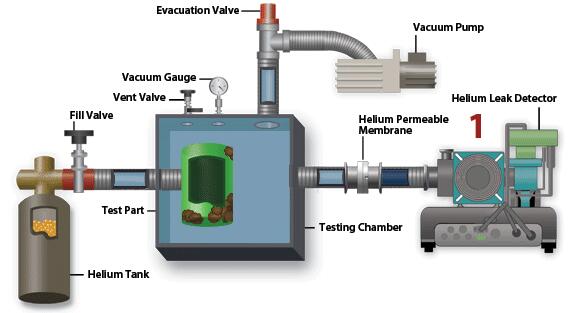

Helium mass spectrometer leak detection technology is an indispensable technology in the field of vacuum leak detection. It is widely used in resistance furnace leak detection because of its high leak detection efficiency, simple operation, sensitive response, high precision and not easy to be interfered by other gases. Helium mass spectrometer leak detector is based on the principle of mass spectrometry, using helium as leak gas to make a gas tightness detector.

It is composed of ion source, analyzer, collector, cold cathode ionization gauge, mass spectrometry chamber, air extraction system and electrical part. The electrons emitted from the filaments in the mass spectrometry chamber oscillate back and forth in the chamber, and collide with the indoor gas and helium entering the chamber through the leakage hole to ionize them into positive ions. These helium ions enter the magnetic field under the action of the accelerating electric field, which deflects due to the action of Lorentz force, forming an arc-shaped orbit. Changing the accelerating voltage can make different quality ions pass through the magnetic field and the receiving gap It is detected when it reaches the receiving pole. Helium injection method and helium absorption method are the two most commonly used methods of helium mass spectrometer leak detector in resistance furnace.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)