Why choose LD side channel blowers

LD side channel blower of advantages:

1. Compact structure: beautiful appearance, good stability, convenient installation and maintenance.

2. Stable operation: the optimized impeller reduces the axial force to a low level, and has an efficient impeller. After static and dynamic balance correction, the whole machine runs smoothly. Without any damping device, the bearing amplitude is ≤ 0.04mm.

3. Low noise: when the fan is running, there is no mechanical friction, and reasonable blade shape line is adopted to reduce the sound to low. The noise produced by the fan is high-frequency noise. As long as there are obstacles, it can be sound insulated, so there is almost no noise outside the fan room.

4. Oil free machinery: the bearing of the fan is lubricated with grease, and the service life of the bearing is more than three years. The fan does not produce oil and gas during operation. For fans with special requirements, molybdenum disulfide lithium grease is used to lubricate bearings.

5. Impeller: the impeller adopts special composite linear, which reduces internal leakage and improves volume efficiency.

6 easy to adjust: the inlet end butterfly valve regulates the flow and the outlet end butterfly valve regulates the pressure.

7. Driving mode: usually two pole asynchronous motor or four pole motor. According to the different power grid, different voltage motors can be used.

8. Seal: except for the inlet ring, labyrinth seal is installed at both ends of each stage impeller, interstage and casing to prevent gas leakage.

LD side channel blower purpose:

1. Powder conveying

2. Paper pulp dehydration

3. Textile cutting cloth dust collection

4. Special for shuttleless loom

5. Paper (cloth) cutting machine pad

6. Air pump for glass industry and ice factory

7. Sewage treatment waterfall

8. Air supply by dust in Tunnel Engineering

9. Industrial yellow air

10. Aquaculture oxygen supply

11. Heavy oil spray

LD side channel blower of features:

1. Small, light, high dust, low noise, high air volume and high pressure

2. Use aluminum alloy material, greatly reduce the weight, and achieve the purpose of lightweight

3. The motor is designed by i.e.c. (above 1HP), totally closed external fan type aluminum frame motor, with special axis design

4. Special blade design, high pressure – large air volume – noise – long service life

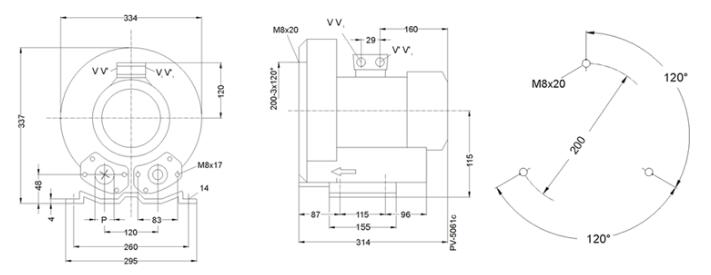

Size

Company strength

1500 square meters of large capacity storage capacity. Complete specifications, large inventory, short delivery time, ready to meet your needs.

Professional R & D, production r & D team to ensure that we have the ability to design, improve and produce in a system.

Professional maintenance team, pay attention to every detail.

Professional after-sales service team, dedicated to every customer service.

CNC precision CNC equipment.

The company conducts regular training for employees, and the trainers have professional application knowledge and rich experience in vacuum.