2SK-20 water ring vacuum pump operating procedures

One. Purpose

This code is formulated to regulate the use, maintenance and maintenance of 2SK series two-stage water ring vacuum pumps to prevent accidents.

Two. Scope

Suitable for the use, maintenance and maintenance of 2SK series two-stage water ring vacuum pump.

Three.responsibility

2SK series two-stage water ring vacuum pump use, maintenance, maintenance personnel responsible for this procedure.

Four. content.

1. 2SK series two-stage water ring vacuum pump structure and main technical parameters

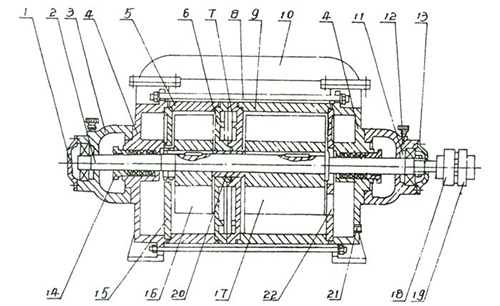

(1) structure

1,Rear shaft pressure cover 2, shaft 3, bearing housing 4, front and rear end covers 5, short pump body 6, middle wall (B) 7, middle wall (A) 8, tension bolts 9, long pump body 10, connect pipe 11, adjustment pad 12, oil cup 13, front shaft pressure cover 14, packing gland 15, Rear cover circular disk 16, short impeller 17, long impeller 18, pump coupling 19, motor coupling 20, shaft sleeve 21, water inlet hole 22. front cover garden plate

(2) Main technical parameters

| Model | Suction capacity | Ultimate vacuum | Power | speed | Water supply | Inlet/outlet diam | Water inlet |

| m³/min | MPa(G) | KW | r/min | L/min | DN(mm) | (mm) | |

| 2SK1.5 | 1.35 | -0.097 | 4 | 1440 | 10-15 | 40 | G1/2” |

| 2SK-3 | 2.7 | -0.098 | 7.5/11 | 1440 | 15-20 | 40 | G1/2” |

| 2SK-6 | 5.4 | -0.098 | 15 | 1460 | 25-35 | 65 | G1/2” |

| 2SK-12 | 10.8 | -0.098 | 22/30 | 970 | 40-50 | 100 | G1/2” |

| 2SK-20 | 18 | -0.098 | 45 | 740 | 60-80 | 125 | G3/4” |

| 2SK-30 | 27 | -0.098 | 55/75 | 740 | 70-90 | 125 | G3/4” |

2. 2SK series two-stage water ring vacuum pump of working principle

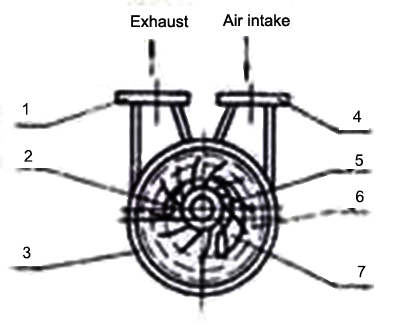

The working principle of water ring vacuum pump is shown in the figure. The impeller (5) is eccentrically installed in the pump body (3). When the impeller rotates, the water is thrown out by centrifugal force. Water ring contact surface area with the impeller wheel, when the impeller along the clockwise rotation, in the first half of the turn in the process of inner surface gradually away from the wheel, water ring cavity formed by two adjacent blades is gradually increasing, gas is pumped through the pump inlet pipe (4), the crescent suction hole within (7) is drawn into the cavity; In the process of the latter half rotation, the inner surface of the water ring is gradually close to the wheel hub, and the cavity between the two adjacent blades is gradually narrowed, so the gas is compressed, thus the pressure keeps increasing. When the pressure increases to greater than the external pressure, the gas is expelled, thus continuously sucking away the gas in the sealed container, forming a certain vacuum.

When the two-stage pump is working, the gas enters the pump through the pipeline valve, and then the gas-water mixture is discharged into the gas-water separator by the pump. Part of the water is replenished by the inlet pipeline, and the excess water is spilled by the overflow pipeline.

1. Exhaust pipe 2. Vent hole 3. Pump body 4. Inlet pipe 5. Impeller 6. Water ring 7

3. 2SK series two-stage water ring vacuum pump of installation

(1) installation of water ring vacuum pump

Before installation, turn the coupling by hand to verify whether the pump is stuck. The foundation of the pump shall be level to ensure that the pump is placed horizontally.

(2) pipeline installation of water ring vacuum pump

Water ring vacuum pump pipeline flange connection should be reliable close, especially the water ring vacuum pump inlet pipe is not a little tight, can not reach the predetermined vacuum. The inlet near the pump must be equipped with gate valves to close before stopping to prevent water in the pump from returning to the inlet or even to the sealed container under pressure from the exhaust pipe. It is best to install a vacuum gauge between the inlet valve and the pump to check whether the pump is normal at any time. Gate valves should also be installed on the water supply pipeline of the water ring vacuum pump to adjust the water supply. The water supply pressure should be around 0.1mpa.

(3) installation of gas-water separator for 2SK water ring vacuum pump

Water ring vacuum pump gas water separator is placed on the ground, the connecting pipe separator shall not be too long, the change may not be too eager, request the connecting pipe and the distance of the pump inlet port, the highest no more than half a meter, up to more than 2 meters, not more than three shift, otherwise the water loss and air flow in the tube will increase, thus increased the pump to the exhaust pressure, thus reducing the flow rate and vacuum degree, increases the power consumption.

4. 2SK water ring vacuum pump before starting the check and prepare

(1) clean the surface and surrounding sundries of the vacuum pump

(2) operators must undergo training before starting work and master the operation rules and safety rules of the equipment

(3) operators must wear labor protection and protective equipment in accordance with the provisions, and slippers and fatigue operations are prohibited

(4) check whether the unit is fully grounded, whether the instruments are normal, whether the bolts of the unit are fastened, whether the pipelines are connected correctly, whether the control switch is out of control, whether the control valve is open correctly, and report any abnormality in time

(5) check the quality of lubricating oil should be in good condition, no emulsification, deterioration and other phenomena.

5. 2SK water ring vacuum pump of start

Before starting, especially the long stop pump must use the hand to turn the coupling several times, to ensure that the rotor can freely rotate. Before starting 2sk-12 and 2sk-20, all the water in the pump body should be released before starting.

Water ring vacuum pump can be started in the following order:

(1) close the gate valve on the inlet pipe;

(2) start the motor (pay attention to the positive and negative rotation of the motor at this time);

(3) open the gate valve on the water supply line and gradually increase the water supply until the water supply meets the specified requirements;

(4) when the pump reaches the ultimate vacuum, open the gate valve on the inlet pipe and the pump starts to work normally;

(5) adjust the packing gland to make the water drip outward. When the vacuum pump works under the ultimate vacuum, the power consumption does not increase due to the explosion caused by the physical action in the water ring vacuum pump. If the explosion sound generated with the increase of power is found, it indicates that the pump has been out of order.

6. 2SK water ring vacuum pump of shutdown

When using the water ring vacuum pump alone, stop the pump in the following order:

(1) close the gate valve on the inlet pipe.

(2) close the gate valve on the water supply line. After stopping water, the pump should not be stopped immediately, so that the pump can continue to turn for 1-2 minutes to discharge part of the working fluid.

(3) turn off the motor.

(4) if the water ring vacuum pump stops for more than one day, the plug at the bottom of the pump must be opened to drain the water.

7. 2SK water ring vacuum pump of maintenance

(1) water ring vacuum pump should be regularly compressed packing, if the packing because of wear and tear can not ensure the seal should be replaced with a new packing, packing can not be pressed too tight, the normal pressure of the packing is allowed to drip out. But the amount should not be too much, the use of oil-soaked asbestos rope as packing.

(2) the ball bearing of the vacuum pump shall have good working conditions, and its working temperature shall not be higher than the ambient temperature of 35℃, but the measured temperature value shall not be greater than 70℃. 2/3 of the whole room of the bearing shall be filled with butter. Normally working bearings shall be filled with oil 3-4 times a year.

8. 2SK water ring vacuum pump and solutions of common faults

|

Malfunction |

Cause of issue |

Solution |

|

Insufficient air extraction |

1. The gap is too large |

Adjustment gap |

|

2. Air leakage at the packing |

Compact or replace packing |

|

|

3. High water ring temperature |

Increase water supply |

|

|

4. Air leakage in the piping system |

Tighten flange bolts, replace gaskets or repair welding cracks, etc. |

|

|

Reduced vacuum |

Pipeline system ① Air leakage at flange joint ②Pipe is cracked |

① Tighten flange bolts or replace gaskets ② Welding repair or replacement |

|

2. Water ring pump ① Filler leak ② The gap between the impeller and the side cover is too large ③ The water ring is hot ④Insufficient water ⑤ Friction and heating of parts cause the temperature of the water ring to rise |

① Press the packing and replace it with a new one ② Replace the gasket to adjust the gap ③ Reduce the temperature of the water supply ④ Increase water supply ⑤ Adjust or reinstall |

|

|

Vibration or There is a noise |

1. Anchor bolts are loose 2. There is foreign material grinding in the pump Leaf fall 4. Cavitation |

Tighten the anchor bolts Stop the pump and check for foreign objects Replace impeller Open the suction pipe valve |

|

Bearing heating |

1. Insufficient lubricant 2. The packing pressure is too tight 3. No seal water or insufficient 4. The bearing or shaft or bearing frame is too tight, so that the clearance between the ball and the inner and outer ring is too small, causing friction |

Check lubrication and refuel Properly loosen the packing gland Supply sealed water or increase the amount of water Adjusting the fit of the bearing to the shaft or bearing frame |

|

Difficult to start |

1. After long-term shutdown, rust inside the pump 2. Packing compaction 3. Partial wear between impeller and pump body |

Rotate the impeller several times by hand or special tool Gum Pine Filling Gland Reinstall and adjust |