Application of EVP Screw Pumps in PET Sheet Extrusion Industry

With the rapid growth of demand for high-quality plastic sheets in packaging, electronics, automotive, and construction industries, PET (Polyethylene Terephthalate) sheet extrusion technology has been widely adopted. The production process places high demands on melt purity, extrusion stability, and vacuum degassing performance.To ensure uniform melt delivery, stable pressure, and continuous production, screw pumps play a crucial role in PET sheet extrusion systems.

EVP screw pumps, with their stable flow output, high temperature and pressure resistance, excellent wear and corrosion resistance, and long-term reliability, have become the ideal choice for melt conveying and metering in PET sheet extrusion lines.

I.Specific Applications of EVP Screw Pumps in PET Sheet Extrusion Production

1.Stable Melt Conveying

In PET extrusion systems, after the melt is plasticized and degassed by a twin-screw extruder, it must be conveyed steadily to the die head.The EVP screw pump, driven by precisely meshing twin screws, ensures stable flow with minimal pressure fluctuation, preventing thickness variations in the sheet caused by melt flow pulsations before the die.

Pump Functions:

(1) Ensure continuous and stable conveying, eliminating extruder pulsation.

(2) Provide precise pressure control to improve sheet thickness uniformity.

(3) Reduce pressure fluctuation at the die head and ensure a smooth, glossy sheet surface.

2.Melt Metering and Pressure Stabilization

Screw pumps feature a constant displacement design, maintaining a steady output pressure even under changing viscosity and flow conditions.In PET sheet production, they play a key role in metering and system pressure stabilization.

Pump Functions:

(1) Precisely control melt flow to achieve consistent sheet thickness.

(2) Stabilize die head feeding pressure and reduce cross-directional thickness variations.

(3) Improve process automation accuracy, supporting digitalized production control.

3.Support for Vacuum Degassing and Melt Purification

When recycled PET material is used, the melt may contain residual moisture or low molecular volatiles.The screw pump works in coordination with the vacuum degassing system, maintaining stable flow to prevent back flow or pulsation that could affect degassing efficiency..

Pump Functions:

(1)Provide constant melt flow, ensuring stable vacuum pressure in the degassing chamber.

(2) Prevent re-entrainment of gases, improving degassing efficiency.

(3) Enhance product transparency and impact resistance.

4.Multilayer Co-extrusion and Recycled Material Conveying

Multilayer PET sheets are often produced using several extruders and screw pumps, where each pump independently conveys and meters the melt for each layer.EVP screw pumps support multi-stream conveying and operate reliably under high-temperature, high-viscosity conditions, ensuring accurate layer-to-layer flow matching.

Pump Functions:

(1) Enable precise layer ratio control in multilayer co-extrusion, improving sheet structure stability.

(2) Support high recycled material ratios, reducing raw material costs.

(3) Ensure long-term, pulse-free, and clog-free operation.

II.Core Advantages of EVP Screw Pumps in the PET Sheet Industry

1.Constant Flow Output and Pressure Stability

EVP screw pumps feature precision synchronous drive technology, achieving truly pulsation-free conveying—ideal for extrusion processes requiring extreme melt stability.

2.Excellent Adaptability to High Temperature and Viscosity

Made of high-temperature resistant alloy steel and with special surface treatment, it can operate for extended periods at temperatures up to 350°C.Stable operation, supporting unattended continuous operation

3.Outstanding Wear and Leak Resistance

Key components are nitrided and hardened; sealing systems can be customized with high-temperature mechanical seals or fluororubber seals to ensure zero leakage during long-term operation.

4. High Efficiency and Easy Maintenance

Mechanical transmission efficiency exceeds 90%; the compact pump chamber structure allows easy maintenance with long service life for wear parts.

5. Versatile Process Compatibility

A single EVP screw pump can be applied in PET, PC, PMMA, and PLA extrusion lines—suitable for both single-layer and multilayer sheet production.

III. Conclusion

With its high precision, low pulsation, high-temperature resistance, and long service life, the EVP screw pump has become an essential component in PET sheet extrusion systems.It significantly improves melt conveying stability and sheet thickness consistency, while enhancing product appearance quality and production efficiency.

For optimal performance, it is recommended to select the pump model based on extruder capacity, melt viscosity, system pressure, and die size—maximizing process efficiency and supporting energy savings, quality enhancement, and intelligent manufacturing.

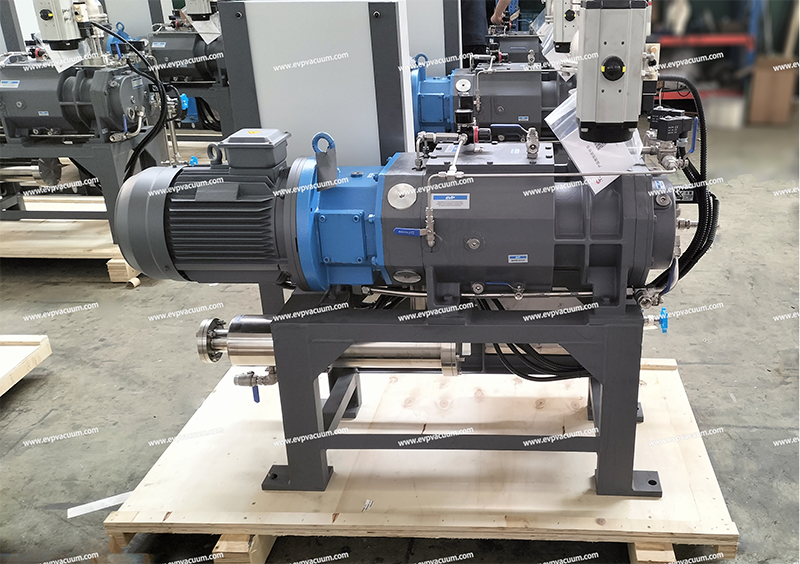

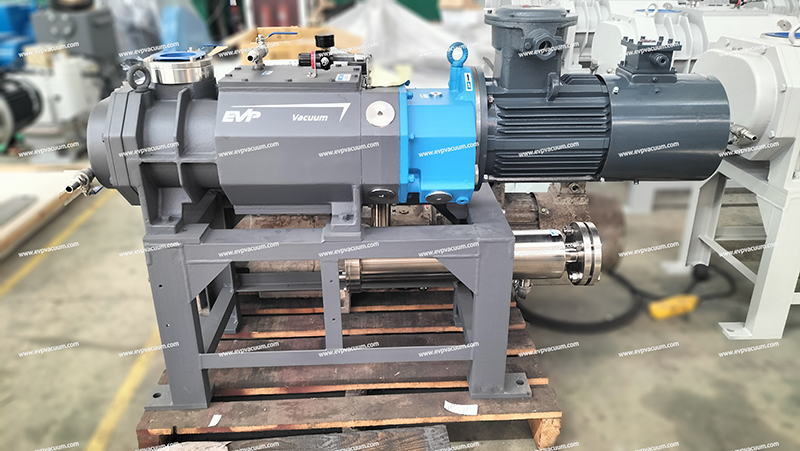

Shipping Image Reference:

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)