buy vacuum pumps

Several factors must be considered when buy vacuum pumps. First, your choice should be adapted to your intended use, which will allow you to determine technology, lubrication, chemical resistance, vacuum and necessary flow.

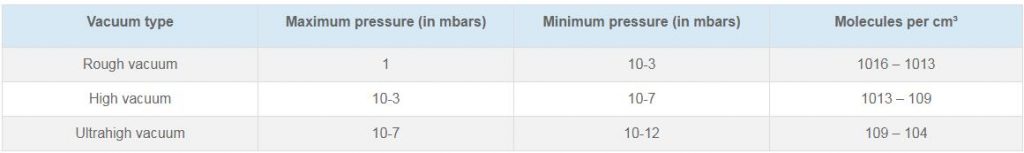

The basic factors that guide you to buy vacuum pumps are quality and required vacuum. There are several types of vacuum: rough or low vacuum, high vacuum and ultra-high vacuum. The difference between the three is the scarcity of the number of molecules obtained, which is measured by the pressure of residual gases. The weaker the pressure, the weaker the molecular number per cm. As a result, the vacuum quality is higher.

We refer to:

You must also consider the following characteristics:

Flow rate of pump: Flow rate is related to the drainage time of the machine. Therefore, it is necessary to evaluate the capacity of the vacuum pump according to the process requirements in order to generate the required pumping speed (volume flow) and mass flow. Usually, the higher the velocity of flow, the shorter the drainage time. The table above shows the number of remaining molecules per cubic centimeter, depending on the type of vacuum selected.

Chemical compatibility: It is necessary to consider the compatibility of the gas used in your application with the vacuum pump selected by analyzing all the problems that the equipment may encounter.

Lubrication: You must ask yourself if it is necessary to lubricate the vacuum pump. Lubricated vacuum pumps have higher efficiency and resistance. However, it does require very regular maintenance. In laboratory environment, it is best to use dry vacuum pump.

Maintenance and Cost: According to the criteria listed above, it is necessary to analyze the frequency of maintenance cycles. This will determine the total cost of installation, which must take into account the purchase price as well as operating and maintenance costs.

vacuum pumps types:

Liquid ring vacuum pump

Scroll Vacuum Pump

Rotary vane vacuum pump

Roots vacuum pump

Dry vacuum pump

Your choice of vacuum pump will depend on the type of vacuum required, as well as the price and durability of the required technology.

When should buy rotary vane vacuum pump?

If you want to find high performance vacuum pumps at low cost, you are advised to consider buy rotary vane vacuum pumps.

Rotary vane vacuum pump is small and compact, and can achieve vacuum degree. They are particularly effective for water-borne samples and high boiling point solvents. Steam can be captured even before it comes into contact with the pump.

Rotary vane vacuum pump needs oil to operate. The presence of oil can ensure perfect air tightness, constant and efficient lubrication of moving parts, and excellent heat dissipation performance, which can be used for cooling vacuum pumps.

However, in order to ensure the effective operation of the pump, regular maintenance should be organized. One of the drawbacks is the need to replace oil regularly to reduce the risk of wear and tear. It is recommended to replace it every 3,000 hours.

When should buy liquid ring vacuum pump?

The liquid ring vacuum pump operates by providing centrifugal liquid on the pump wall. This will form a liquid ring, thus maintaining the air tightness of the pump.

Liquid ring vacuum pumps have many advantages, which may be useful if you work in distilleries, refineries, power plants, mines, sugar refineries and other industries. These vacuum pumps are for liquids, fine solid particles or vapors. In addition, their isothermal compression is an ideal choice for explosive and heat sensitive products, which can ensure high safety. The liquid ring vacuum pump can also be used for vacuum filtration, water extraction, water removal from pulp, mineral recovery and ash treatment during paper making.

The maximum flow rate of these powerful pumps is 30,000 m/ h, which allows you to reduce and increase the pressure. However, we recommend that you pay attention to the saturated vapor pressure of the liquid ring. The minimum pressure of the vacuum pump must not be lower than the saturation pressure of the liquid ring, otherwise the liquid ring may evaporate. This will damage the air tightness of the vacuum pump.

When should buy scroll vacuum pump?

scroll vacuum pumps are used for clean and dry vacuum pumps. Therefore, they are widely used in research fields and laboratories.

scroll vacuum pumps use two spiral vortices to pump and compress liquid or gas media. One helix is fixed, while the other is eccentric. It is this eccentric motion that makes the gas compress.

The scroll vacuum pump is quiet, compact and does not require oil. The air tightness of vacuum pump is produced by joint helix. Seals must be replaced regularly to ensure optimum airtightness, so regular maintenance is required. The main disadvantage of these pumps is that they are easy to damage debris and introduced particles, which are easy to corrode the spiral seal.

What are the main uses of vacuum pumps?

Vacuum pumps are used in many different fields. They are mainly found in laboratories, medical and pharmaceutical industries, filtration and mass spectrometry analysis.

Each of these uses requires a specific type of vacuum. For example, mass spectrometry requires pressure between 10-3 and 10-4 mbar. Therefore, it is not necessary to use technology that can produce ultra-high vacuum.

If your application involves the agro-food industry, drying, vacuum metallurgy or distillation, then you will need a rough vacuum.

If you are involved in vacuum mixing or beam welding, we recommend that you switch to high vacuum.

However, if you are engaged in surface state physics or particle acceleration, we recommend the use of ultra-high vacuum. If you encounter any problems in buy vacuum pumps, please feel free to consult us.contact@evpvacuum.com

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)