Dry Screw Vacuum Pump in Food Industry

Preservation of Frozen Vegetables by Screw Vacuum Pump

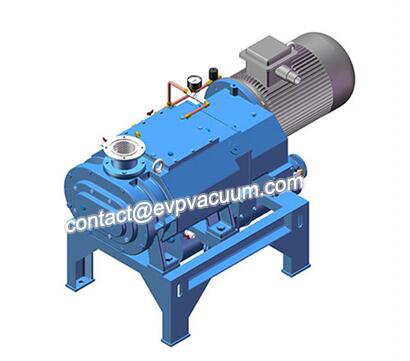

Screw vacuum pump is more and more widely used, with high vacuum, high efficiency, low power consumption, small occupancy and user acceptance! In addition to its applications in the pharmaceutical, chemical, printing and dyeing, and electronic industries, our dry screw vacuum pump has been successfully implemented in the field of vegetable preservation and food freezing industry.

Due to the high requirement of freshness and nutritional value of vegetable, the traditional frozen storage has been unable to meet the needs of customers. Under these conditions, the first dry screw vacuum pump in China has been developed and manufactured with high efficiency and integrated fresh-keeping drying equipment. The most critical equipment is the dry screw vacuum pump. Compared with the water ring vacuum pump (easy to operate, high vacuum, high efficiency, no water), the rotary vane vacuum pump (no oil, no exhaust gas, almost no maintenance, large pumping volume, short time), the reciprocating vacuum pump (occupies a large area, noise, low efficiency, large water consumption), not only occupies a small area, but mainly has high vacuum, stability and high efficiency. Compared with traditional cold storage, vegetable drying has incomparable advantages.

This kind of vacuum fast fresh-keeping equipment is almost always exported, which is 7.8 million or even higher. Therefore, the equipment has broad market prospects and incomparable use value!

Screw vacuum unit is not only used in small-scale preservation industry, it is known that: screw vacuum pump unit (Roots screw unit) in the field of food refrigeration has also achieved very good results.

The newly developed 100% oil-free screw vacuum pump ensures higher safety and efficiency in food and packaging processes.

Manufacturers and consumers are increasingly demanding the quality, shelf life and resource efficiency of food and packaging processes. This is more suitable for perishable products such as meat or fish. Vacuum is considered to be an advantageous technology and has made an important contribution to optimizing these processes.

“Many meat processing and packaging users can’t actually tolerate vacuum pump oil discharge, which improves the safety of rollover, filling, vacuum packaging and thermoforming applications. Another advantage of oil-free vacuum pumps is that they are cheaper to own because they require less maintenance and replacement of spare parts. In addition to the principle of oil-free screw, other mature components and principles of vacuum pump series will be transferred, including bearing structure and belt drive, to synchronize the rotor.

Air cooling reduces total cost of ownership

Usually, dry pumps are water-cooled, but air-cooled. This reduces operating costs by simplifying installation and debugging.

Screw Vacuum Pump of Wide Application

The new pump stands out for its long-term operation and robustness. For example, other products lose their termination pressure or reduce pumping speed due to wear and tear of the inner coating. However, performance is achieved throughout the pressure range and life cycle. This makes it an ideal choice for simple applications that emit low humidity, such as packaging of cold products. In addition, the pump is also very suitable for more rigorous processes requiring large amounts of water vapor, for example, when hot meals at temperatures up to 95 degrees C have to be rapidly cooled by evaporative cooling. “In addition to the air/steam mixture from the process, the screw vacuum pump can also handle the expected air pollution well. These are organic acids, spices, vinegar or other residues.

Verified in real life

The new pump has successfully passed many qualified on-site durability tests and is suitable for various food applications – roll, pallet sealing and thermoforming. In all applications, it shows very good performance, users achieve fast cycle time and low final pressure.

Prospective pumps

Prospective products have been successfully developed, which is expected to set new standards for food processing and packaging market. This is not only because there is no oil, but also because of noise behavior, robust design and low life cost.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)